High-strength polypeptide hydrogel preparation method

A hydrogel, high-strength technology, used in non-active medical preparations, pharmaceutical formulations, non-active components of polymer compounds, etc. problems, to achieve the effect of improving the mechanical strength and improving the ability to form glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

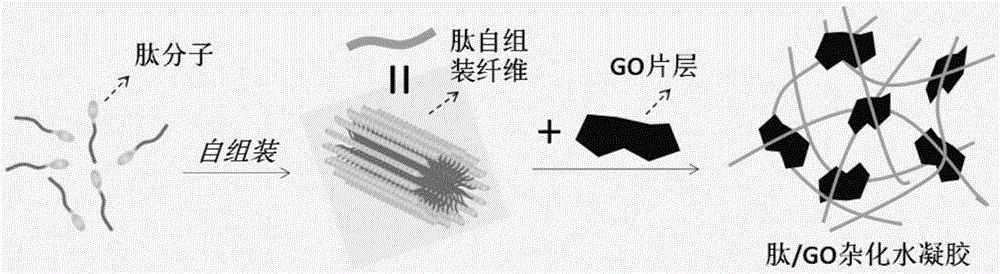

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation I 3 K polypeptide molecular 4.0mmol / L aqueous solution, ultrasonic mixing, ultrasonic power 100W, ultrasonic time 10min; stand at room temperature for 3 days to make it self-assemble into a long fiber structure, at this time the system can not form a hydrogel;

[0036] (2) Add GO sheets with a length of 300±200nm, a width of 300±200nm, and a thickness of 1-2nm in the solution containing the polypeptide long fiber structure, so that the concentration of the GO sheet is 0.1 mg / mL (that is, every mL Add 0.1 mg GO flakes to the solution), and ultrasonically mix, the ultrasonic power is 100W, and the ultrasonic time is 12min; the pH value of the mixed solution is adjusted to 10.5 by using NaOH solution with a concentration of 0.5mol / L, and it is allowed to stand at room temperature for 6 hours to form hybrid water gel.

[0037]The storage modulus (G') of the hydrogel obtained in Example 1 can reach 4000Pa, the energy dissipation modulus (G") can reach 500Pa,...

Embodiment 2

[0039] (1) Prepare K 3 A 3 I 3 G 3 V 3 Polypeptide molecule 4.0mmol / L aqueous solution, ultrasonic mixing, ultrasonic power 100W, ultrasonic time 10min; stand at room temperature for 3 days to make it self-assemble into a long fiber structure;

[0040] (2) Add GO sheets with a length of 300±200nm, a width of 300±200nm, and a thickness of 1-2nm to the above-mentioned long fiber structure solution, so that the concentration of the GO sheet is 0.02mg / mL, ultrasonically mix, and the ultrasonic power 100W, ultrasonic time is 10min; use 0.5mol / L NaOH solution to adjust the pH of the mixed solution to 10.0, and let it stand at room temperature for 6 hours to form a hybrid hydrogel.

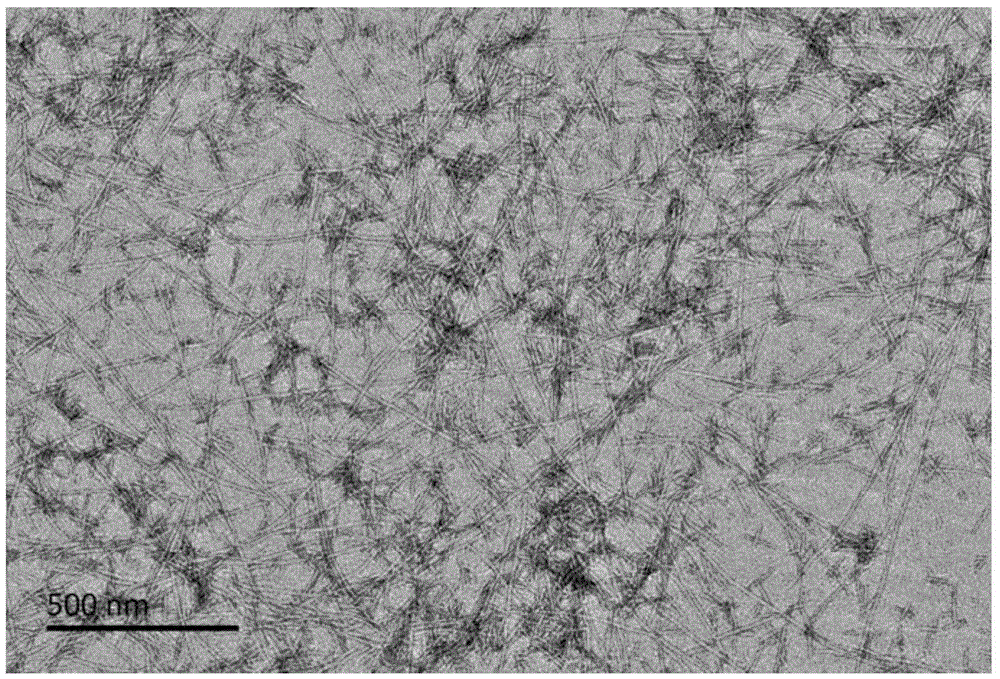

[0041] The storage modulus (G') of the hydrogel obtained in Example 2 can reach 5000Pa, the energy dissipation modulus (G") can reach 600Pa, and the gel pore size is less than 500nm; the self-supporting hybrid Hydrogels.

Embodiment 3

[0043] (1) Prepare K 3 A 3 I 3 G 3 V 3 Polypeptide molecule 4.0mmol / L aqueous solution, ultrasonic mixing, ultrasonic power 100W, ultrasonic time 10min; stand at room temperature for 3 days to make it self-assemble into a long fiber structure;

[0044] (2) Add GO sheets with a length of 300±200nm, a width of 300±200nm, and a thickness of 1-2nm to the above-mentioned long fiber structure solution, so that the concentration of the GO sheet is 0.1mg / mL, ultrasonically mix, and the ultrasonic power 100W, ultrasonic time is 10min; use 0.5mol / L NaOH solution to adjust the pH of the mixed solution to 10.0, and let it stand at room temperature for 6 hours to form a hybrid hydrogel.

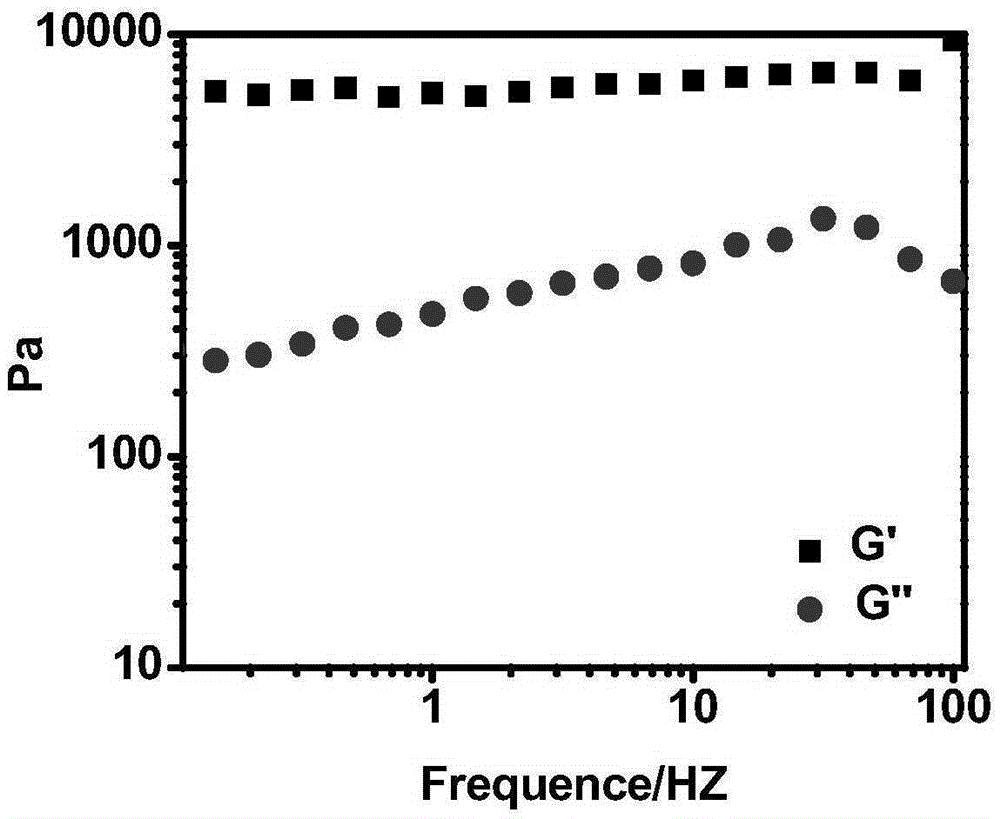

[0045] The storage modulus (G') of the hydrogel obtained in Example 3 can reach 6000Pa, the loss modulus (G") can reach 1000Pa, and the gel pore size is less than 500nm. image 3 It is the rheological measurement result of the hybrid hydrogel of this embodiment; a self-supporting hybrid hydrogel can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com