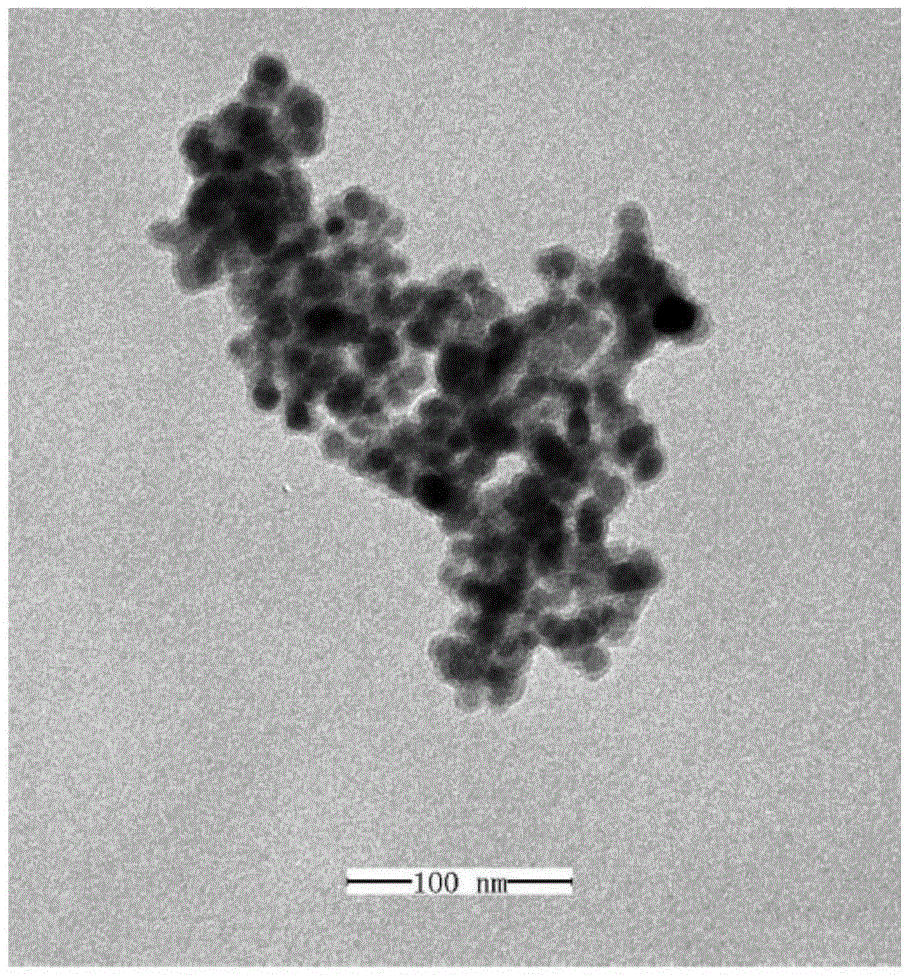

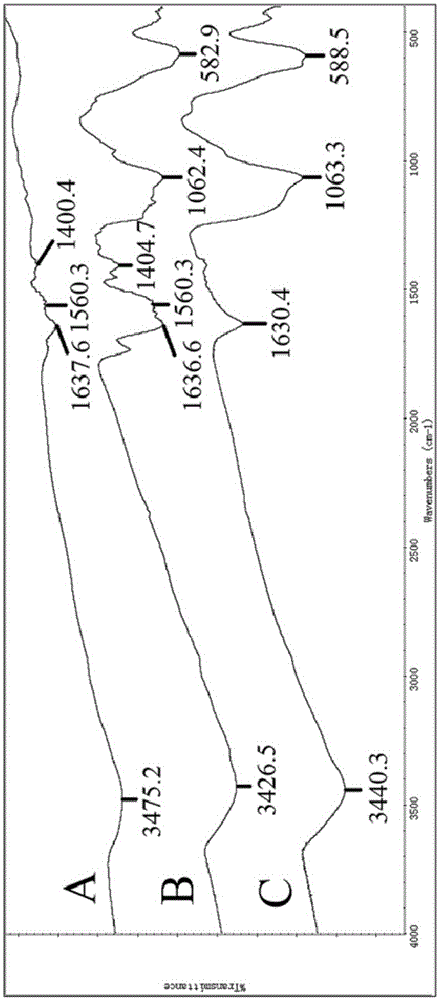

Magnetic nano-particle adsorbent and preparation method and application thereof

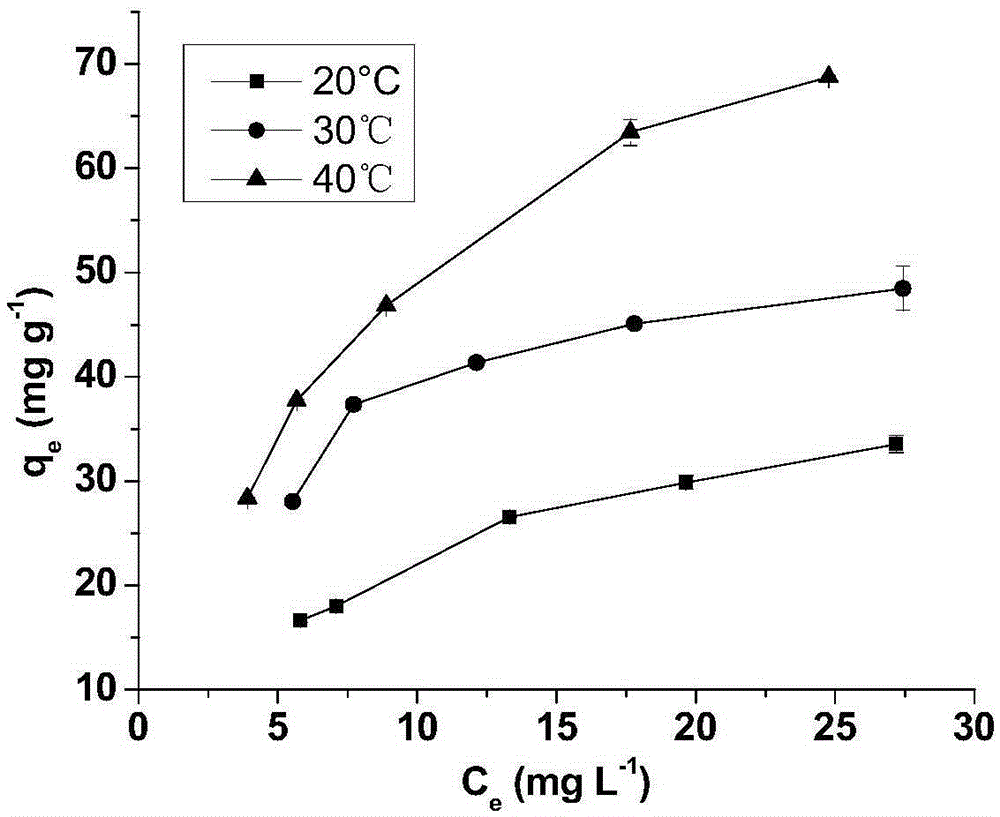

A magnetic nanoparticle and nanoparticle technology, applied in the field of water pollution treatment, can solve the problems of intolerance to water quality environment, no specificity, low adsorption capacity, etc., and achieve the effect of low cost, fast elution, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] In a second aspect, the present invention provides a method for preparing a magnetic nanoparticle adsorbent, comprising the following steps:

[0020] (1) Fe 3 o 4 After mixing the nanoparticles with ethanol and concentrated ammonia water evenly, heat them in the reaction vessel to 30-50°C, maintain a constant temperature, add tetraethyl orthosilicate dropwise after 4-6 minutes, and magnetically separate the magnetic particles after 24-36 hours of reaction, and wash to obtain Coated intermediate product particles;

[0021] (2) Mix the coated intermediate product particles obtained in step (1) with toluene evenly, stir and heat in the reaction vessel to 30-50°C, maintain a constant temperature, and add 3-aminopropyltriethoxy dropwise after 5-30min base silane, after 24-36 hours of reaction, magnetically separate the magnetic particles and wash to obtain the intermediate product particles after connection;

[0022] (3) Mix the connected intermediate product particles ob...

Embodiment 1

[0030] (1) With 2.6gFe 3 o 4 Nanoparticles are the precursor, ethanol is the solvent, add concentrated ammonia water with a mass fraction of 30%, accounting for 4.25% of the total volume; mix well, heat to 40°C in a constant temperature stirring water bath in a reaction vessel, maintain a constant temperature, and add dropwise after 5 minutes Tetraethyl orthosilicate, accounted for Fe 3 o 4 0.5 times the mass of nanoparticles; after 24 hours of reaction, magnetically separate the magnetic particles, wash with ethanol and toluene, and obtain coated intermediate product particles;

[0031] (2) Disperse the magnetic particles obtained in step (1) in toluene, mix them evenly, heat them in a constant temperature stirring water bath to 40°C in a reaction vessel, maintain a constant temperature, add 3-aminopropyltriethoxysilane dropwise after 5 minutes, accounted for Fe 3 o 4 0.8 times the mass of nanoparticles; after 24 hours of reaction, the magnetic particles are magnetically...

Embodiment 2

[0042] (1) With 2.6gFe 3 o 4 Nanoparticles are the precursor, ethanol is the solvent, add concentrated ammonia water with a mass fraction of 30%, accounting for 4.25% of the total volume fraction; after mixing evenly, heat it to 30°C in a constant temperature stirring water bath in a reaction vessel, maintain a constant temperature, and add dropwise after 4 minutes Tetraethyl orthosilicate, accounted for Fe 3 o 4 0.4 times the mass of nanoparticles; after 24 hours of reaction, the magnetic particles are separated magnetically, washed with ethanol and toluene, and the coated intermediate product particles are obtained;

[0043] (2) Disperse the magnetic particles obtained in step (1) in toluene, mix them evenly, heat them in a constant temperature stirring water bath in the reaction vessel to 30°C, maintain a constant temperature, add 3-aminopropyltriethoxysilane dropwise after 5 minutes, accounted for Fe 3 o 4 0.6 times the mass of nanoparticles; after 24 hours of reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com