Method for converting greenhouse gas into carbon

A greenhouse gas, room temperature technology, applied in the field of fixation and utilization of greenhouse gases, can solve the problems of low conversion rate, high energy consumption, slow reaction rate, etc., and achieve the effect of simple and easy control and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

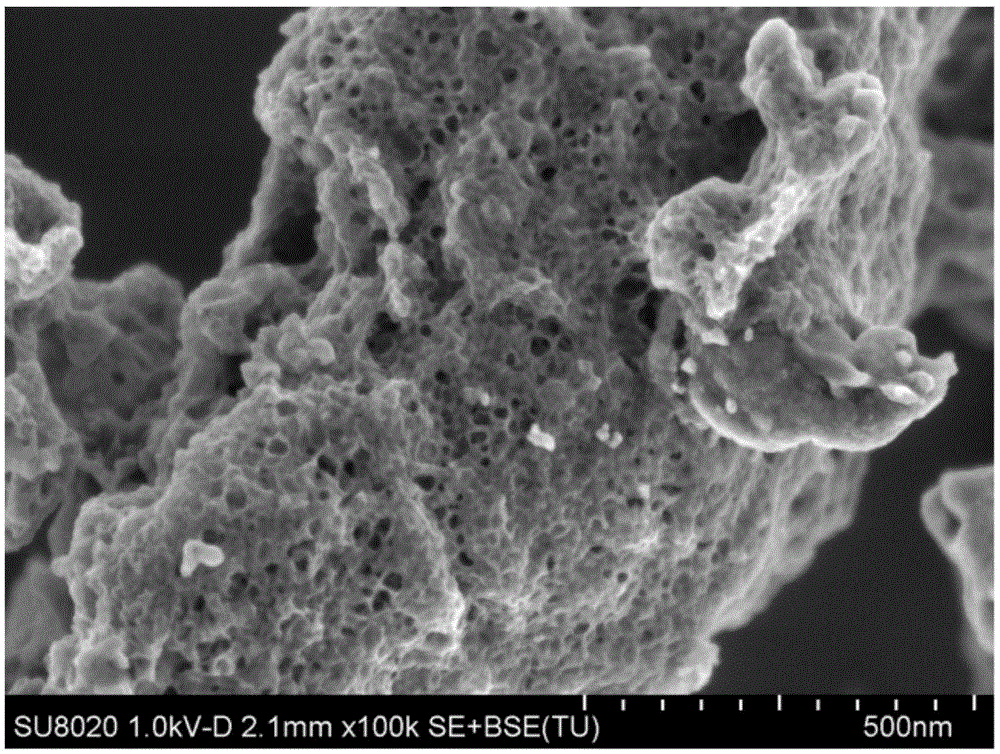

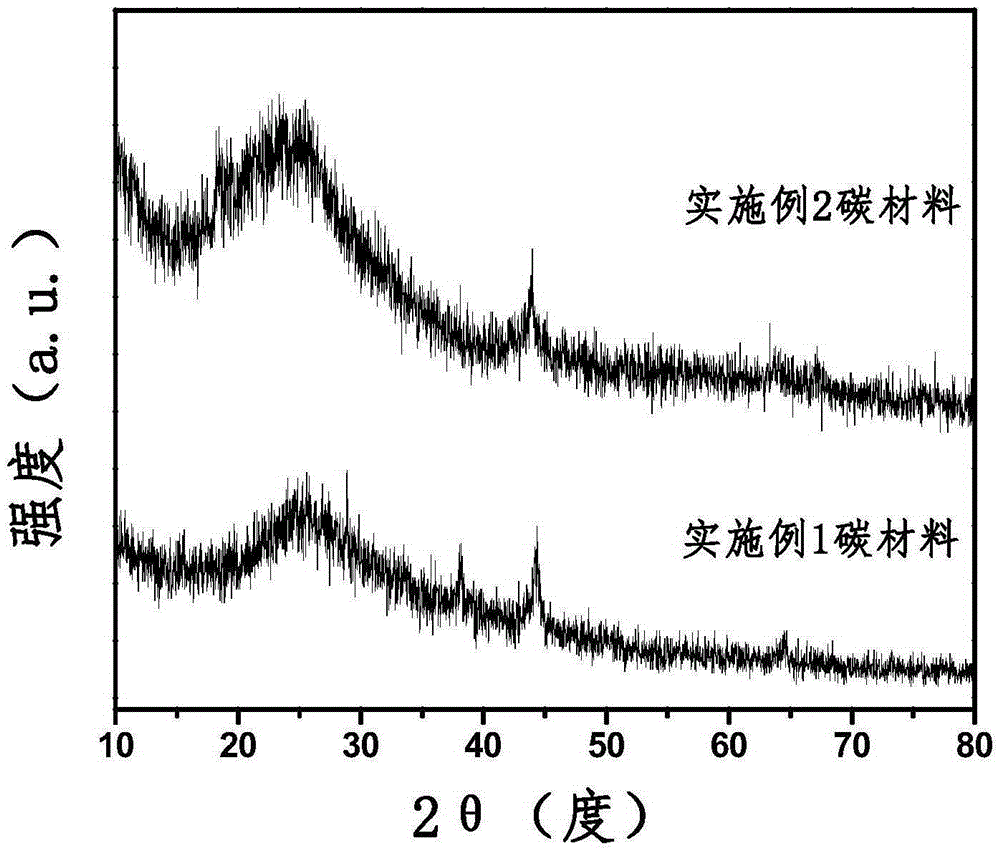

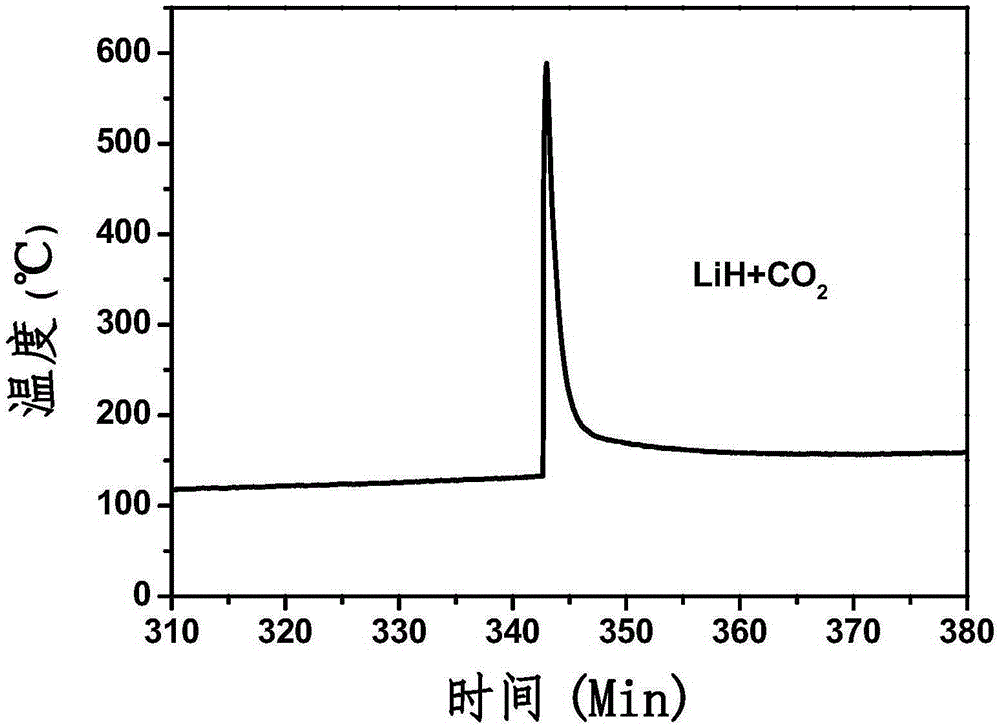

Embodiment 1

[0035] In a dry air atmosphere, disperse 2g of lithium hydride powder into the bottom of the dry reactor, then seal the reactor and evacuate it, and then slowly introduce CO into the reactor. 2 Gas to a pressure of 6MPa, and finally inject 0.5ml of water into the reactor through pressure difference. The heat released by the reaction of water and lithium hydride can trigger the reaction of lithium hydride and CO 2gas reaction. After 5 minutes of reaction time, after the reaction is completed and cooled, first collect the gas in the reactor, then take out the solid product in the reactor and soak it in 8wt% dilute hydrochloric acid for 3 hours, then filter it, wash it with water, and dry it , the carbon material (purity greater than 95%) can be obtained.

Embodiment 2

[0037] Under an argon atmosphere, put 1 g of lithium hydride powder into the bottom of a dry tubular reactor, and slowly introduce CO into the tubular reactor. 2 Gas to a pressure of 5MPa, and then increase the temperature to 180°C at a rate of 0.5°C / min. Then cool down, first collect the gas in the reactor, then take out the solid product in the reactor to a concentration of 5wt% dilute hydrochloric acid and soak it for 12h, then filter it, wash it with water, and dry it to obtain the carbon material (purity greater than 95 %).

Embodiment 3

[0039] Under the protection of nitrogen atmosphere, disperse 1.5g lithium hydride powder into the bottom of the dry reactor, then seal the reactor and evacuate it, and then use the gas pressure difference to quickly (flow rate is about 950m / s) into the reactor into CO 2 Gas to a pressure of 7MPa. CO 2 The kinetic energy of the gas can trigger lithium hydride and CO 2 gas reaction. After 3 minutes of reaction time, after the reaction is finished and cooled, first collect the gas in the reactor, then take out the solid product in the reactor and soak it in 8wt% dilute hydrochloric acid for 6 hours, then filter it, wash it with water, and dry it , the carbon material (purity greater than 95%) can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com