Weather-resistant pearl powder coating special for aluminum material and preparation method of weather-resistant pearl powder coating

A powder coating and weather resistance technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as improper powder coating formula and process, shedding of powder boiled pearl powder, unstable mortar resistance, etc., to achieve beautiful Bright pearlescent metal effect, strong adhesion and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

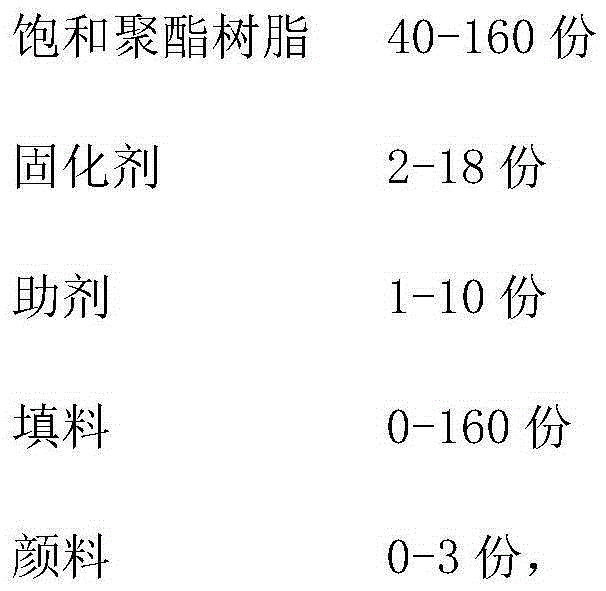

[0039] A special weather-resistant pearlescent powder coating for aluminum materials, which is formed by bonding together a base powder and a weather-resistant pearlescent pigment at a weight ratio of 100:1, and the base powder includes the following components by weight:

[0040]

[0041] Preparation:

[0042] 1. Prepare base powder:

[0043] (a) Weigh saturated polyester resin, curing agent TGIC, titanium dioxide, barium sulfate, leveling agent, benzoin, other additives and pigments in the mixing tank according to the above weight ratio, fully mix and crush for 1 to 10 minutes ;

[0044] (b) The crushed material enters the twin-screw extruder for extrusion; the heating temperature of the extruder is controlled at 80-120°C;

[0045] (c) The extruded material is pressed into tablets, cooled, pulverized into a powder with a particle size (equivalent particle size D50) of 30-45um, and then sieved to obtain a special weather-resistant pearlescent powder coating for aluminum....

Embodiment 2

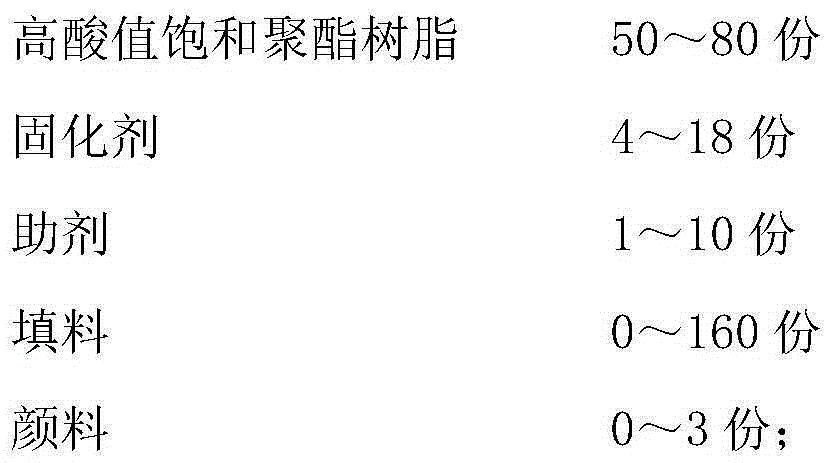

[0053] A special weather-resistant pearlescent powder coating for aluminum, which is formed by bonding together a base powder and a weather-resistant pearlescent pigment at a weight ratio of 100:3, and the base powder includes the following components by weight:

[0054]

[0055]

[0056] Preparation:

[0057] 1. Prepare base powder:

[0058] (a) Weigh saturated polyester resin, curing agent TGIC, titanium dioxide, barium sulfate, leveling agent, benzoin, other additives and pigments in the mixing tank according to the above weight ratio, fully mix and crush for 1 to 10 minutes ;

[0059] (b) The crushed material enters the twin-screw extruder for extrusion; the heating temperature of the extruder is controlled at 80-120°C;

[0060] (c) The extruded material is pressed into tablets, cooled, pulverized into a powder with a particle size (equivalent particle size D50) of 30-45um, and then sieved to obtain a special weather-resistant pearlescent powder coating for aluminu...

Embodiment 3

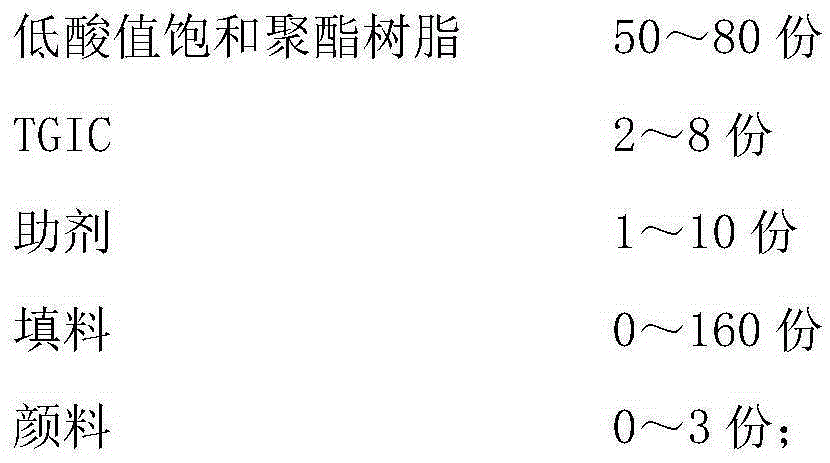

[0069] A special weather-resistant pearlescent powder coating for aluminum materials, which is formed by bonding together a primer and a weather-resistant pearlescent pigment at a weight ratio of 100:1. The primer is composed of composition A and composition B.

[0070] The composition B contains the following components by weight:

[0071]

[0072] The composition B contains the following components by weight:

[0073]

[0074] Preparation:

[0075] 1. Prepare base powder:

[0076] (a) Weighing composition A and composition B according to the weight ratio, respectively placing them in a mixing tank, fully mixing and crushing for 1 to 10 minutes;

[0077] (b) The crushed materials of composition A and composition B are respectively extruded into a twin-screw extruder; the heating temperature of the extruder is controlled at 80-120°C;

[0078] (c) The extruded composition A material and composition B material are respectively tabletted, cooled, and crushed, and then re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com