UV super-hydrophobic polyimide paint prepared by room temperature reaction and used for wood material surface

A water polyimide, wood material technology, applied in the direction of coating, can solve the problems of limitation, flammability, inability to withstand high temperature, etc., achieve excellent sealing performance and heat resistance, and solve the effect of high conversion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

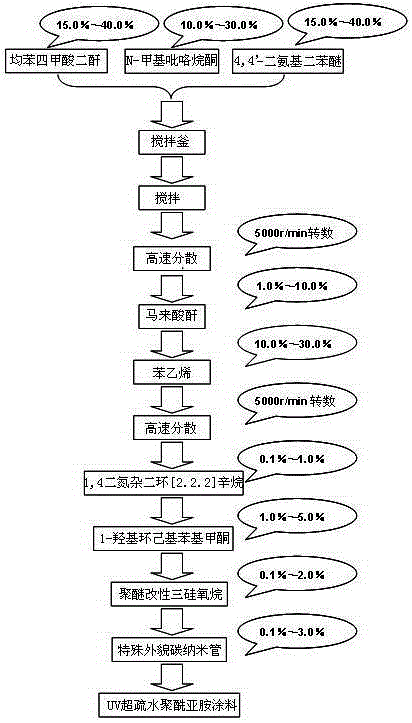

[0037] Such as figure 1 Shown, a kind of room temperature reaction preparation can be used for the preparation method of the UV superhydrophobic polyimide coating of wooden material surface, comprises the following steps:

[0038] (1) Add pyromellitic dianhydride, N-methylpyrrolidone, and 4,4'-diaminodiphenyl ether into the stirring tank in sequence, and stir evenly, wherein the weight part of pyromellitic dianhydride is controlled at 15-40 parts, the weight part of N-methylpyrrolidone is controlled at 10-30 parts, and the weight part of 4,4'-diaminodiphenyl ether is controlled at 15-40 parts;

[0039] (2) The system is dispersed at room temperature for 24-48 hours at a speed of 3000-5000r / min;

[0040] (3) Add maleic anhydride and styrene to the above system in sequence to adjust to an appropriate viscosity, wherein the parts by weight of maleic anhydride are controlled at 1 to 10 parts, and the parts by weight of styrene are controlled at 10 to 30 parts;

[0041] (4) The sys...

Embodiment 1

[0046] Embodiment 1: room temperature reaction prepares the preparation method that can be used for the UV superhydrophobic polyimide coating of wooden material surface, comprises the following steps:

[0047] (1) Add 40kg of pyromellitic dianhydride, 10kg of N-methylpyrrolidone, and 36kg of 4,4'-diaminodiphenyl ether into the stirring tank in sequence, and stir;

[0048] (2) The system is dispersed at room temperature for 46 hours at a speed of 3000-5000r / min;

[0049] (3) Then add 1kg of maleic anhydride and 10kg of styrene to the above system in turn to adjust to an appropriate viscosity (coating -4 cups for 15~35s);

[0050] (4) The system is dispersed at room temperature for 24 hours at a speed of 3000-5000r / min;

[0051] (5) After the reaction is over, slowly add 0.1kg of 1,4-diazabicyclo[2.2.2]octane, 1.8kg of photoinitiator 1-hydroxycyclohexyl phenyl ketone and 1kg of Leveling agent polyether-modified trisiloxane, and finally add 0.1 kg of carbon nanotubes with speci...

Embodiment 2

[0052] Embodiment 2: room temperature reaction preparation can be used for the preparation method of the UV superhydrophobic polyimide coating of wooden material surface, comprises the following steps:

[0053] (1) Add 15kg of pyromellitic dianhydride, 30kg of N-methylpyrrolidone, and 15kg of 4,4'-diaminodiphenyl ether into the stirring tank in sequence, and stir;

[0054] (2) The system is dispersed at room temperature for 24 hours at a speed of 3000-5000r / min;

[0055] (3) Then add 1kg of maleic anhydride and 30kg of styrene to the above system in turn to adjust to an appropriate viscosity (coating -4 cups for 15~35s);

[0056] (4) The system is dispersed at room temperature for 42 hours at a speed of 3000-5000r / min;

[0057] (5) After the reaction is over, slowly add 0.1kg of 1,4-diazabicyclo[2.2.2]octane, 5kg of photoinitiator 1-hydroxycyclohexyl phenyl ketone and 2kg of fluid under high-speed stirring conditions. Leveling agent polyether modified trisiloxane, and finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com