Durable, antistatic and dustproof finishing agent for flocking fabrics and preparation method thereof

An antistatic and anti-dusting technology, which is applied in fiber treatment, textiles and papermaking, etc., to achieve the effect of reducing adhesion, embedding or hooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

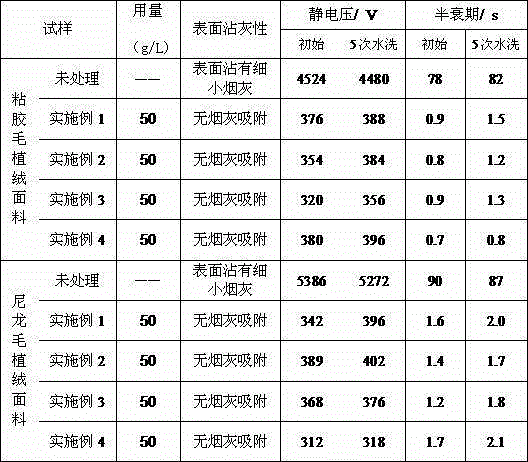

Examples

Embodiment 1

[0032] Raw material by weight ratio

[0033] (1) 50 parts of methyl hydrogen-containing silicone oil (mass fraction of active hydrogen is 0.15%), 99 parts of allyl polyethoxy polypropoxy ether (number average molecular weight 1200), 2 parts of vinyltrimethoxysilane, Put it into a reaction kettle equipped with a condenser and a stirring device, raise the temperature to 70-72°C, add 0.12 parts of chloroplatinic acid ethanol solution (15mgPt / mL), and then raise the temperature to 90°C-95°C, and carry out in this temperature range Addition reaction for 3 hours to obtain polyether and alkoxy co-modified silicone oil;

[0034] (2) Cool down the modified silicone oil obtained in step 1 to 30-40°C, add 604 parts of water to dilute;

[0035] (3) Add 12 parts of glyoxal aqueous solution (40% by mass) and 400 parts of guanidine hydrochloride aqueous solution (20% by mass) to the product obtained in step 2, and stir evenly to obtain durable antistatic and antistatic flocking fabrics. Du...

Embodiment 2

[0037] (1) 70 parts of methyl hydrogen-containing silicone oil (mass fraction of active hydrogen is 0.15%), 80 parts of allyl polyethoxy polypropoxy ether (number average molecular weight 1200), 5 parts of vinyl triethoxysilane , put it into a reaction kettle equipped with a condenser and a stirring device, raise the temperature to 70-72°C, add 0.15 parts of chloroplatinic acid ethanol solution (15mgPt / mL), and then raise the temperature to 90°C-95°C. Addition reaction was carried out for 3.5 hours to obtain polyether and alkoxy co-modified silicone oil;

[0038] (2) Cool down the modified silicone oil obtained in step 1 to 30-40°C, and add 620 parts of water to dilute;

[0039] (3) Add 10 parts of glyoxal aqueous solution (40% by mass) and 500 parts of guanidine hydrochloride aqueous solution (20% by mass) to the product obtained in step 2, and stir evenly to obtain durable antistatic and antistatic flocking fabrics. Dust finishing agent.

Embodiment 3

[0041] (1) 100 parts of methyl hydrogen-containing silicone oil (mass fraction of active hydrogen is 0.15%), 120 parts of allyl polyethoxy polypropoxy ether (number average molecular weight 1200), 4 parts of vinyltrimethoxysilane, Put it into a reaction kettle equipped with a condenser and a stirring device, raise the temperature to 70-72°C, add 0.16 parts of chloroplatinic acid ethanol solution (15mgPt / mL), then raise the temperature to 90°C-95°C, and carry out the process under this temperature range Addition reaction for 4 hours to obtain polyether and alkoxy co-modified silicone oil;

[0042] (2) Cool down the modified silicone oil obtained in step 1 to 30-40°C, and add 820 parts of water to dilute;

[0043] (3) Add 15 parts of glyoxal aqueous solution (40% by mass) and 450 parts of guanidine hydrochloride aqueous solution (20% by mass) to the product obtained in step 2, and stir evenly to obtain durable antistatic and antistatic flocking fabrics. Dust finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com