Nanosheet piled lithium iron phosphate/graphene composite material and preparation method thereof

A graphene composite and lithium iron phosphate technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as low electronic conductivity, slow lithium ion migration rate, and limit wide application, so as to improve conductivity , reduce the specific surface area, reduce the effect of the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

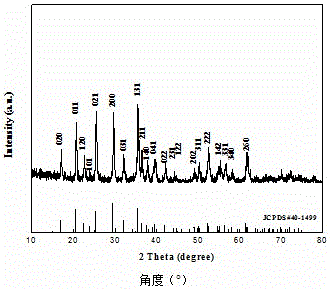

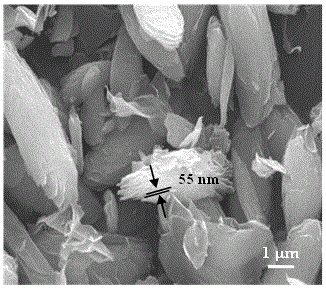

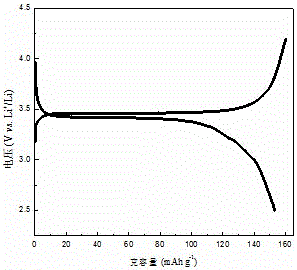

[0028] In the lithium iron phosphate / graphene composite material stacked by nanosheets in this embodiment, the nanosheet-shaped lithium iron phosphate is stacked in situ to form a micron-sized shuttle-shaped particle, and is composited with graphene to form a positive electrode material; the thickness of the lithium iron phosphate nanosheet It is 50-55nm; the size of micron-sized shuttle particles is 4.0-5.5μm.

[0029] The preparation method comprises the following steps:

[0030] (1) Dissolve 0.03mol of lithium hydroxide and 0.01mol of ferrous sulfate heptahydrate in 40ml of ethylene glycol to prepare lithium hydroxide solution with a concentration of 0.75M and ferrous sulfate solution with a concentration of 0.25M;

[0031] (2) Add 0.01 mol of phosphoric acid and the solution containing lithium source obtained in step (1) dropwise into the solution containing iron source obtained in step (1), and add 0.5 g of ammonium persulfate and 1.6 g of graphene oxide respectively to f...

Embodiment 2

[0038] In the lithium iron phosphate / graphene composite material stacked by nanosheets in this embodiment, the nanosheet-shaped lithium iron phosphate is stacked in situ to form a micron-sized shuttle-shaped particle, and is composited with graphene to form a positive electrode material; the thickness of the lithium iron phosphate nanosheet It is 45-50nm; the size of micron-sized shuttle particles is 3.5-4.5μm.

[0039] The preparation method comprises the following steps:

[0040] (1) Dissolve 0.03mol of lithium hydroxide and 0.01mol of ferrous sulfate heptahydrate in 40ml of ethylene glycol to prepare lithium hydroxide solution with a concentration of 0.75M and ferrous sulfate solution with a concentration of 0.25M;

[0041] (2) Add 0.015 mol of phosphoric acid and the solution containing the lithium source obtained in step (1) dropwise into the solution containing the iron source obtained in step (1), and add 0.5 g of ammonium persulfate and 0.8 g of graphene oxide respecti...

Embodiment 3

[0047] In the lithium iron phosphate / graphene composite material stacked by nanosheets in this embodiment, the nanosheet-shaped lithium iron phosphate is stacked in situ to form a micron-sized shuttle-shaped particle, and is composited with graphene to form a positive electrode material; the thickness of the lithium iron phosphate nanosheet It is 55-60nm; the size of micron-sized shuttle particles is 4.0-5.0μm.

[0048] The preparation method comprises the following steps:

[0049] (1) Dissolve 0.027mol of lithium hydroxide and 0.01mol of ferrous sulfate heptahydrate in 40ml of ethylene glycol to prepare lithium hydroxide solution with a concentration of 0.338M and ferrous sulfate solution with a concentration of 0.125M;

[0050] (2) Add 0.01 mol of phosphoric acid and the solution containing lithium source obtained in step (1) dropwise into the solution containing iron source obtained in step (1), and add 0.5 g of ammonium persulfate and 1.6 g of graphene oxide respectively t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com