Lithium-rich manganese-based cathode material with crosslinking structure and preparation method thereof

A cathode material, lithium-rich manganese-based technology, applied in structural parts, chemical instruments and methods, nanotechnology for materials and surface science, etc. Violent problems, etc., to achieve the effect of low resistance to release and embedding, reasonable pore size distribution, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix ethanol and deionized water at a volume ratio of 9.0:1.0, add 0.0015 mol of nickel nitrate, 0.0015 mol of cobalt nitrate and 0.005 mol of manganese acetate, and ultrasonically stir to dissolve them completely. Transfer the above mixed solution to a microwave reactor, adjust the microwave power to 350W, heat the mixed solution to a reflux state, maintain the reflux state, control the temperature at 72°C, slowly add 0.3mol ammonia water to it, and keep the reaction for 10 minutes after the dropwise addition , cooled at room temperature, centrifuged, collected the precipitate, washed, and dried in vacuum to prepare the nickel cobalt manganese hydroxide precursor. Subsequently, the precursor and lithium carbonate were thoroughly mixed and ground at a molar ratio of 1:1.23, calcined in a tube furnace at 888°C for 10 h, cooled and then ground to obtain the final lithium-rich manganese-based cathode material.

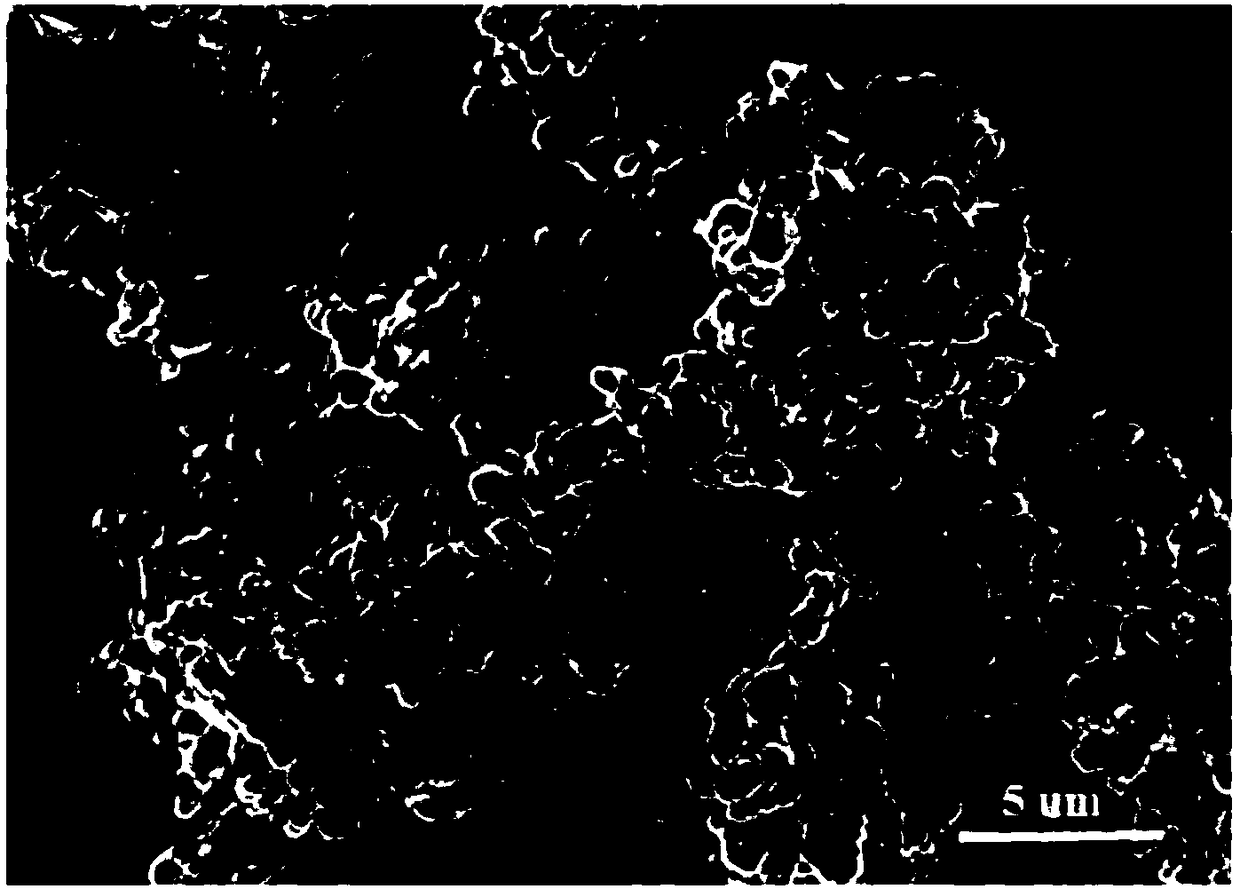

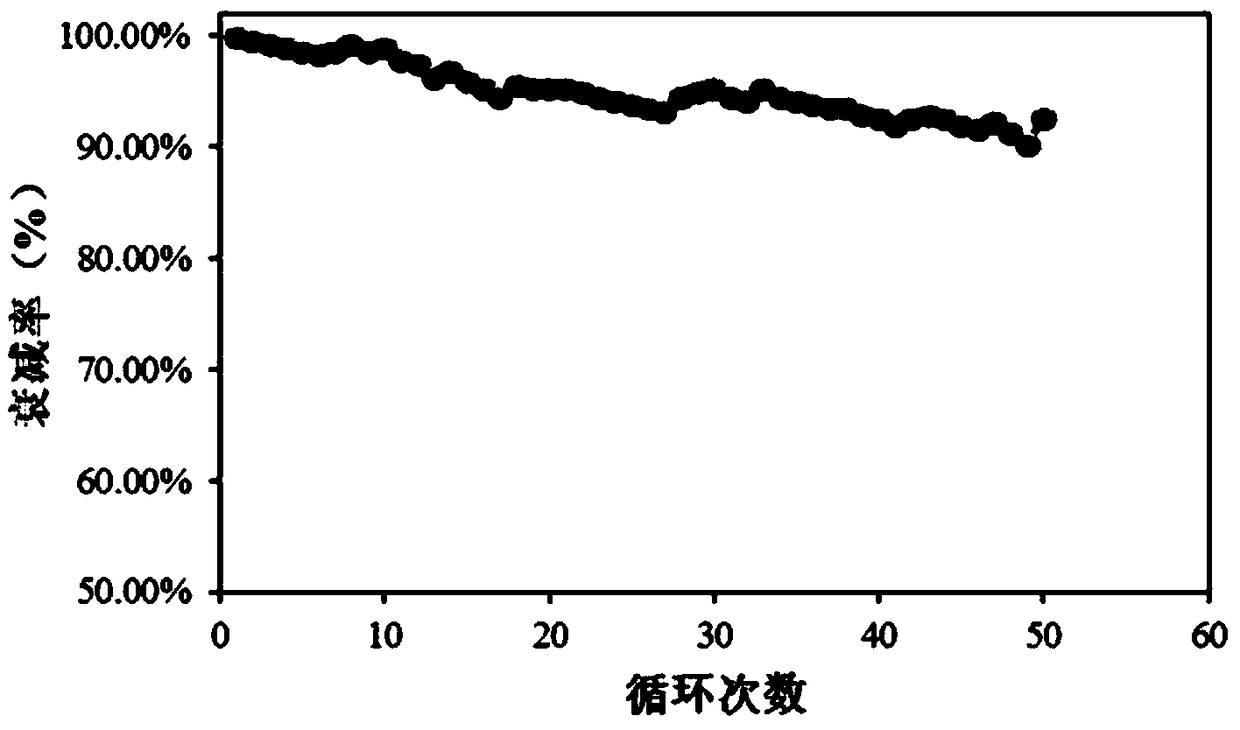

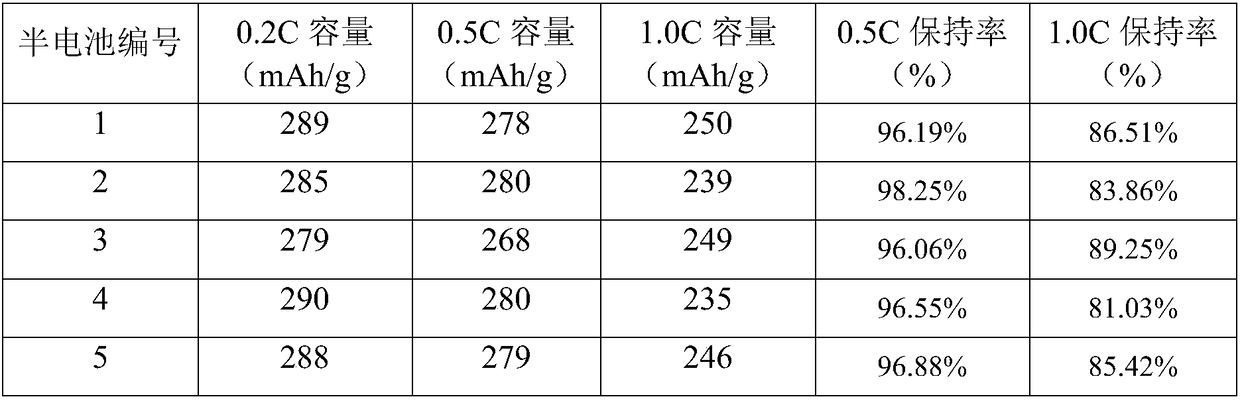

[0032] SEM test: figure 1 SEM images of the as-prepared lithi...

Embodiment 2

[0040] Mix methanol and deionized water at a volume ratio of 9.5:0.5, add 0.002mol of nickel sulfate, 0.002mol of cobalt acetate and 0.004mol of manganese acetate, and ultrasonically stir to dissolve it completely. Transfer the above mixed solution to a medium microwave reactor, adjust the microwave power to 250W, heat the mixed solution to the reflux state, maintain the reflux state, maintain the temperature at 68°C, slowly add 0.4mol ammonia water to it, and keep the reaction for 12 minutes after the end. Cool at room temperature, centrifuge, collect the precipitate, wash, and vacuum-dry to prepare the nickel-cobalt-manganese hydroxide precursor. Subsequently, the precursor and lithium carbonate were thoroughly mixed and ground at a molar ratio of 1:1.22, calcined in a tube furnace at 900°C for 10 h, cooled and then ground to obtain the final lithium-rich manganese-based cathode material.

Embodiment 3

[0042]Mix absolute ethanol, methanol and deionized water at a volume ratio of 6:3:1, add 0.0012mol of nickel nitrate, 0.0012mol of cobalt nitrate and 0.006mol of manganese acetate, and ultrasonically stir to dissolve them completely. Transfer the above mixed solution to a medium microwave reactor, adjust the microwave power to 300W, heat the mixed solution to the reflux state, maintain the reflux state, and maintain the temperature at 70°C, slowly add 0.3mol ammonia water and ammonium bicarbonate aqueous solution to it, and end Afterwards, keep the reaction for 8 minutes, cool at room temperature, and centrifuge to collect the precipitate, wash it, and dry it in vacuum to prepare the nickel-cobalt-manganese hydroxide precursor. Subsequently, the precursor and lithium carbonate were thoroughly mixed and ground at a molar ratio of 1:1.18, calcined in a tube furnace at 950 °C for 8 hours, cooled and then ground to obtain the final lithium-rich manganese-based cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com