A watertight mooring detection cable and a manufacturing process thereof

A technology for detecting cables and watertight systems, used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of insufficient longitudinal watertightness of cables, poor resistance to breaking tensile force, etc., and achieve excellent seawater corrosion resistance. Corrosion of seawater and improvement of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

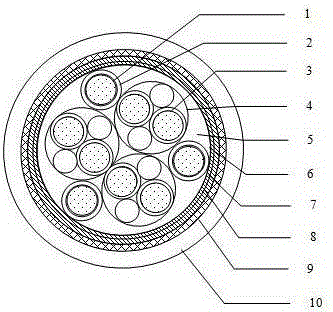

[0030] Example: see figure 1 The structure of the watertight trailing cable in this embodiment is set as: a seven-stranded soft copper wire conductor 1 coated with sealant, and the conductor 1 is extruded with a cross-linked polyethylene insulating layer 2 to form the insulated core of the power line. The conductor The externally extruded low-density polyethylene insulation layer 3 constitutes the signal wire insulation core; the two signal wire insulation cores are twisted to form the insulated core group I4, and the cores are filled with water blocking; three signal insulated core groups I4 and 3 Two power cord insulated cores are twisted into a cable core, a water-blocking glue filling layer I5 is set between the signal insulation core group I and the power line insulation core; the cable core is wrapped around the water-blocking tape layer 6, and the water-blocking tape layer 6 A water-blocking adhesive layer is set outside, the water-blocking adhesive layer is wrapped with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation thickness | aaaaa | aaaaa |

| Insulation thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com