Low temperature desulfurizing, dedusting, mercury-removal, oxidation absorption reduction denitration integrated tower and purification technology

An oxidative absorption, low-temperature technology, applied in the low-temperature desulfurization, oxidative-absorption-reduction-denitrification integrated tower and its purification process, dust removal, and mercury removal fields, can solve the problems of inability to deal with harmful nitrogen oxide gases at the same time, long reaction time, etc. Simple, good purification effect, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

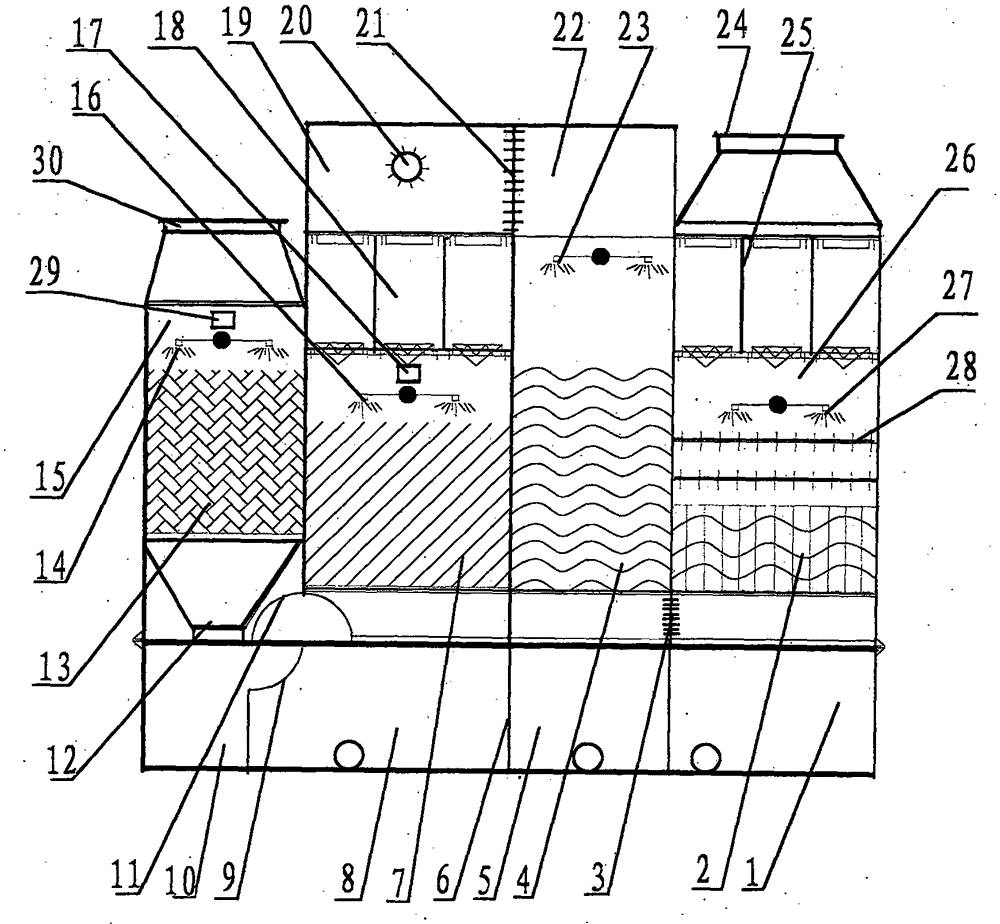

[0014] In the accompanying drawings, the low-temperature desulfurization, dust removal, mercury removal, oxidation, absorption, reduction and denitrification integrated tower of the present invention is mainly composed of a bracket, a water tank, a tower body, a packing layer, a self-excited device, an oxygen injection hole, an oxidant injection port, and a diversion hole. plate, shower and cyclone dehydration device; the water tank 8 is located in the bracket 6, divided into three parts side by side by the partition, the first water tank 10 and the third water tank 1 are equipped with alkali absorption liquid, the second The water tank 5 is filled with a liquid oxidant absorbing liquid; the liquid oxidant absorbing liquid is one of hydrogen peroxide, potassium permanganate, chlorine dioxide or sodium hypochlorite. The tower body is supported by a bracket 6, and the tower body is composed of four towers closely connected side by side from left to right, and a self-excited devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com