Chitosan-based composite adsorbent capable of synergistically and efficiently removing positive and negative ions of heavy metals and preparation method thereof

An anion and cation, composite adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of small adsorption capacity of heavy metal cations, complex preparation process, easy dissolution of iron ions, etc., to achieve Increase the number of adsorption sites, the preparation process is simple and effective, and the effect of improving the adsorption capacity of amphoteric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

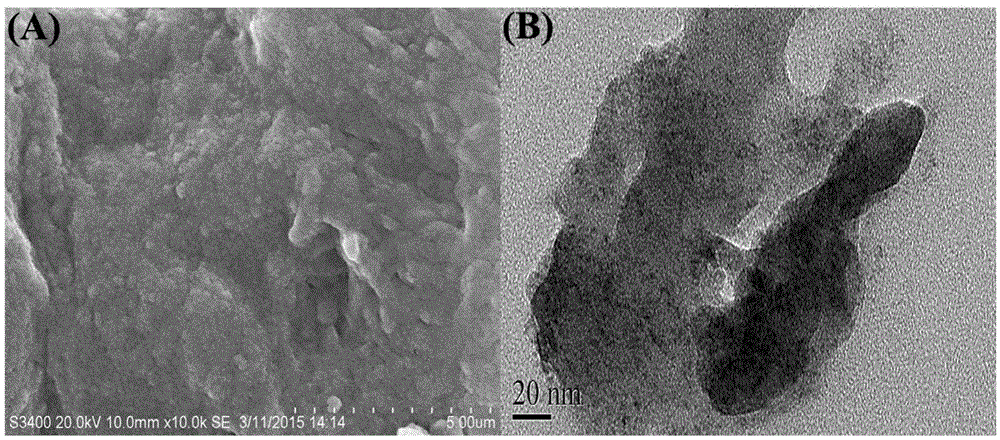

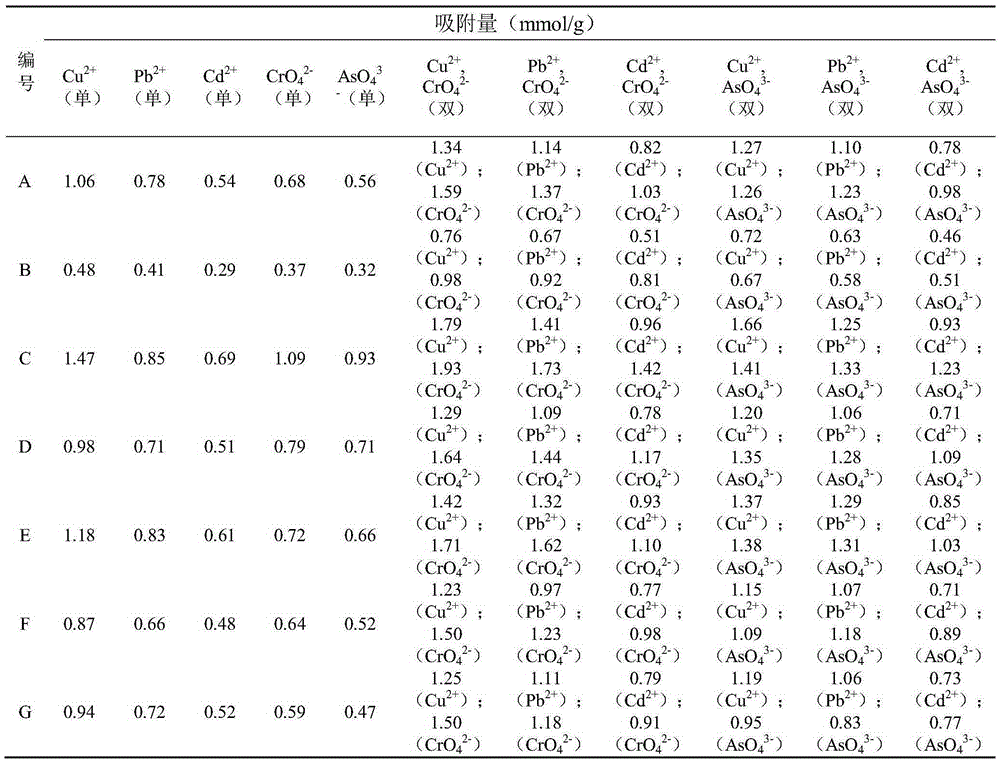

Image

Examples

Embodiment 1

[0032] A chitosan-based composite adsorbent capable of synergistically and efficiently removing heavy metal anions and cations, and its synthesis steps are:

[0033] A) Accurately weigh 3g of chitosan powder and put it into a three-necked flask filled with 100mL of distilled water, then add 2mL of acetic acid dropwise to the solution, mechanically stir at 60°C for 2h until all the chitosan is dissolved to obtain chitosan Mother liquor. Measure 30mL of chitosan mother liquor, add 0.4g of ferric sulfate and 1g of polyethyleneimine to it, stir magnetically at room temperature until uniformly mixed, and then transfer the resulting homogeneous solution to a three-necked flask, and add 0.25mL of ring to it. Oxychloropropane was initially cross-linked by magnetic stirring at 60° C. for 2 hours to obtain a mixed mother liquor.

[0034] B) Pump the mixed mother liquor into 250 mL of a coagulation bath containing 16 g of sodium hydroxide and 13 g of sodium sulfate to solidify into balls, le...

Embodiment 2

[0037] A chitosan-based composite adsorbent capable of synergistically and efficiently removing heavy metal anions and cations, and its synthesis steps are:

[0038] A) Accurately weigh 0.2g of chitosan powder and put it into a three-necked flask filled with 100mL of distilled water, then add 1mL of acetic acid dropwise to the solution, and mechanically stir at 20°C for 4h until all the chitosan is dissolved to obtain chitosan. Sugar mother liquor. Measure 30mL of chitosan mother liquor, add 0.15g of ferric sulfate and 0.3g of polyethyleneimine to it, magnetically stir at room temperature until uniformly mixed, and then transfer the resulting homogeneous solution to a three-necked flask, and add 0.15mL of The epichlorohydrin is preliminarily cross-linked by magnetic stirring at 80°C for 20 hours to obtain a mixed mother liquor.

[0039] B) Pump the mixed mother liquor into 250 mL of a coagulation bath containing 2.5 g of sodium hydroxide and 5 g of sodium sulfate to solidify into ...

Embodiment 3

[0042] A chitosan-based composite adsorbent capable of synergistically and efficiently removing heavy metal anions and cations, and its synthesis steps are:

[0043] A) Accurately weigh 5g of chitosan powder and put it into a three-necked flask filled with 100mL of distilled water, then add 8mL of acetic acid dropwise to the solution, and mechanically stir at 80°C for 10h until all the chitosan is dissolved to obtain chitosan Mother liquor. Measure 30 mL of chitosan mother liquor, add 1.8 g of ferric sulfate and 3 g of polyethyleneimine to it, magnetically stir at room temperature until uniformly mixed, and then transfer the resulting uniform solution to a three-necked flask, and add 1.20 mL of ring to it. The oxychloropropane was initially cross-linked by magnetic stirring at a temperature of 20° C. for 4 hours to obtain a mixed mother liquor.

[0044] B) Pump the mixed mother liquor into 250 mL of a coagulation bath containing 50 g of sodium hydroxide and 50 g of sodium sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com