AgVO3/Ag3PO4 heterojunction composite photocatalyst and preparation method and application thereof

A technology of composite light and catalyst, applied in the field of photocatalysis, can solve the problems of low separation rate of photogenerated carriers and affect photocatalytic activity, and achieve the effect of improving visible light catalytic activity and stability, good practical value, and accelerating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

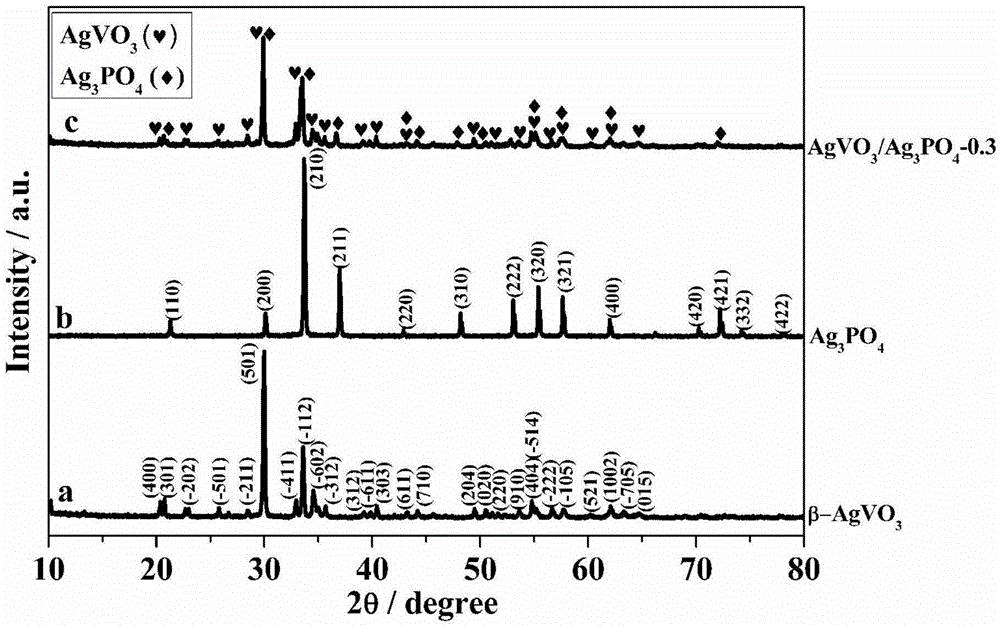

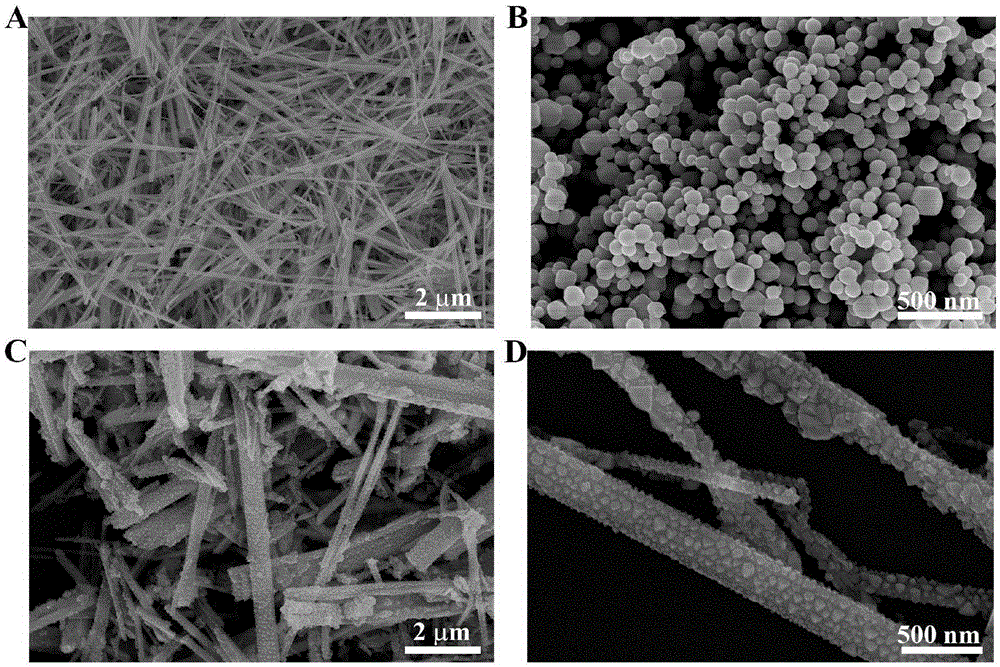

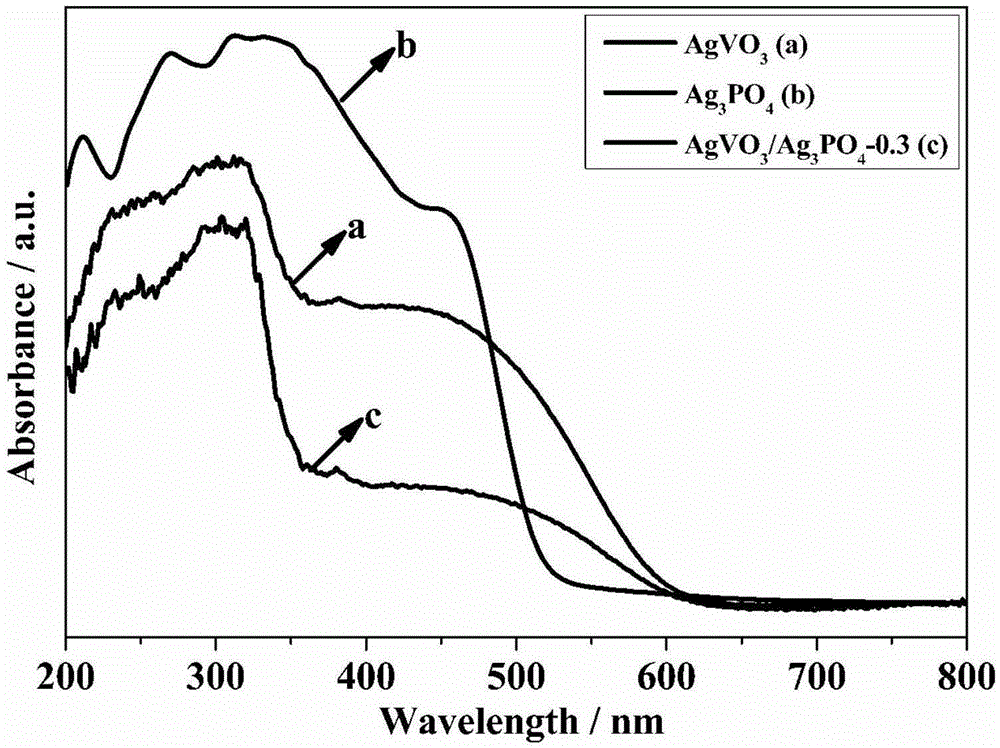

[0041] AgVO 3 / Ag 3 PO 4 Preparation method of heterojunction composite photocatalyst:

[0042] (1) Preparation of AgVO by hydrothermal synthesis 3 Nanobelt: 1.0mmolNH 4 VO 3 Dissolve in 30mL ultrapure water, heat to 80°C and stir continuously to dissolve completely; meanwhile, add 1.0mmolAgNO 3 Dissolve in 30mL ultrapure water, stir to dissolve, and obtain the solution respectively; then the above AgNO 3 The solution was added dropwise to the above NH 4 VO 3 In the solution, use 2.0mol / LNH 3 ·H 2 O solution to adjust the pH of the mixture to 7, and then continue to stir in the dark for 5 hours; after the stirring is completed, the suspension is obtained, and the suspension is transferred to a high-pressure reactor equipped with a polytetrafluoroethylene liner, and placed in an electric heating constant temperature blast drying Heat treatment at 180°C in the oven for 24 hours; after the reaction, cool the reactor to room temperature, and filter the product, after whi...

Embodiment 2

[0051] AgVO 3 / Ag 3 PO 4 Preparation method of heterojunction composite photocatalyst:

[0052] The difference from Example 1 is that adding 0.2mmolNa 3 PO 4 12H 2 O. Weigh the above obtained 1.0mmolAgVO 3 Nanobelts were added to 30mL ultrapure water, ultrasonically dispersed for 30min, and then magnetically stirred for 30min to obtain a dispersion; at the same time, 0.2mmolNa 3 PO 4 12H 2 O was added to 30mL ultrapure water, and magnetically stirred to make it dissolve completely to obtain a solution; then the above-mentioned Na 3 PO 4 The solution was added drop by drop to the above AgVO under magnetic stirring. 3 In the dispersion liquid, the mixed liquid was obtained, and then 2.0mol / LHNO 3 The solution adjusted the pH of the mixed solution to 7, and then continued to stir at room temperature for 8 hours in the dark; after the stirring was completed, the product was filtered by suction, and the precipitate after suction filtration was washed several times with ...

Embodiment 3

[0054] AgVO 3 / Ag 3 PO 4 Preparation method of heterojunction composite photocatalyst:

[0055] The difference from Example 1 is that adding 0.1mmolNa 3 PO 4 12H 2 O. Weigh the above obtained 1.0mmolAgVO 3 Nanobelts were added to 30mL ultrapure water, ultrasonically dispersed for 30min, and then magnetically stirred for 30min to obtain a dispersion; at the same time, 0.1mmol Na 3 PO 4 12H 2 O was added to 30mL ultrapure water, and magnetically stirred to make it dissolve completely to obtain a solution; then the above-mentioned Na 3 PO 4 The solution was added drop by drop to the above AgVO under magnetic stirring. 3 In the dispersion liquid, the mixed liquid was obtained, and then 2.0mol / LHNO 3 The solution adjusted the pH of the mixed solution to 7, and then continued to stir at room temperature for 8 hours in the dark; after the stirring was completed, the product was filtered by suction, and the precipitate after suction filtration was washed several times with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com