Milling method of graphene aluminum-based composite material

An aluminum-based composite material and milling processing technology, which is applied in the direction of metal processing equipment, workpieces, milling machine equipment, etc., can solve the problems of reduced product performance, poor surface roughness of workpieces, and high difficulty coefficient, and achieve high pass rate and high precision. Milling, the effect of avoiding machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

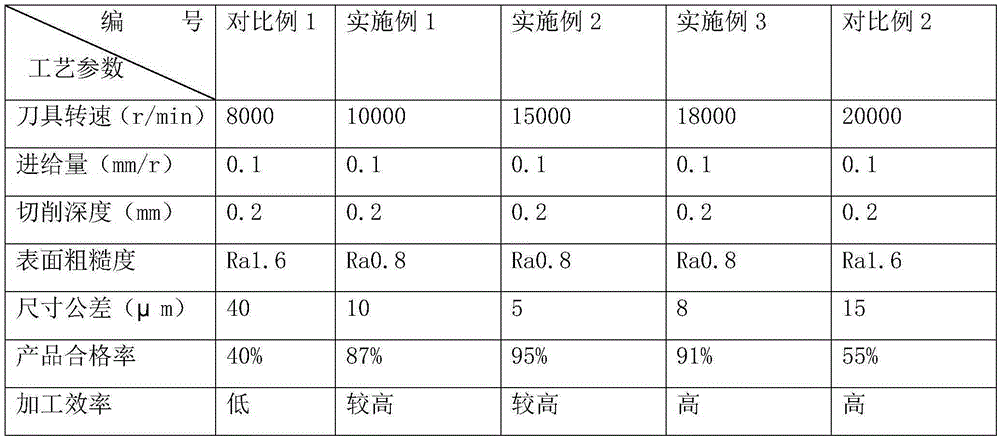

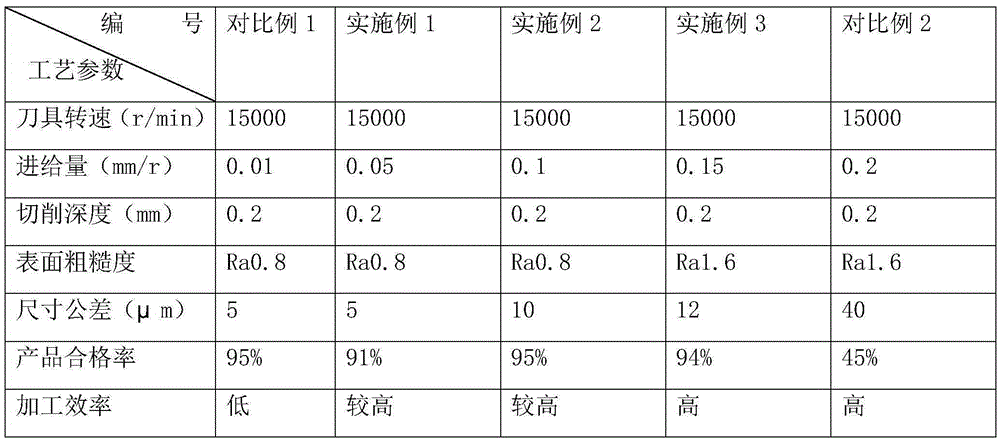

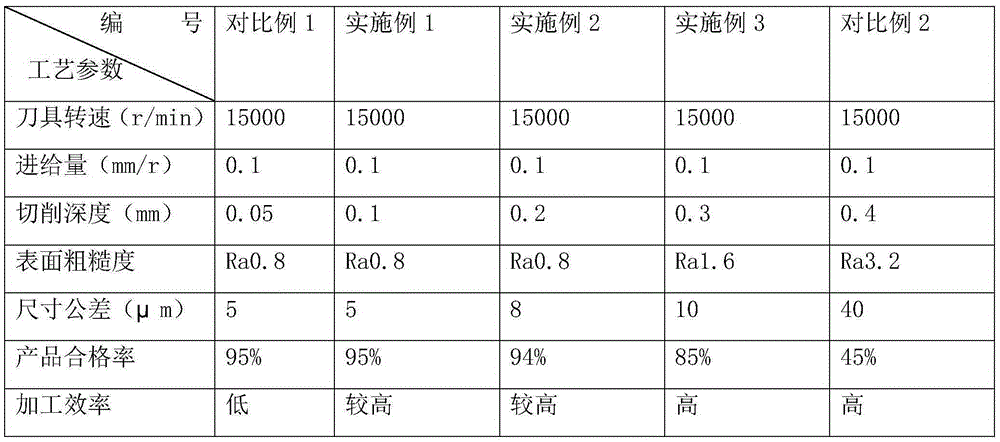

[0017] The milling processing method of graphene-aluminum matrix composite material of the present invention adopts PCD milling cutter to process, and the rotating speed of described PCD milling cutter is 10000~18000r / min, and feed rate is 0.05~0.15mm / r, and cutting depth is 0.1 ~0.3mm, the radial circular runout, end surface circular runout and axial movement of the machine tool spindle are less than 0.02mm.

[0018] The PCD milling cutter is the existing cutter head made of polycrystalline diamond. Compared with the ultrafine tungsten steel milling cutter and the cubic boron carbide milling cutter, it has high hardness, high thermal conductivity, low thermal expansion coefficient, high The advantages of elastic modulus, low coefficient of friction and extremely sharp blades have been tested. During the processing of graphene-aluminum matrix composites, chips are not easy to stick to the tip of the blade to form built-up edge. When cutting workpieces for a long time The dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com