A kind of binder for casting and preparation method thereof

A technology for binders and castings, applied in the field of binders for castings and their preparation, can solve the problems of short service life of organic binders, inability to withstand high temperatures, and easily generate volatile gases, and achieve high temperature resistance performance, The effect of good bond strength and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

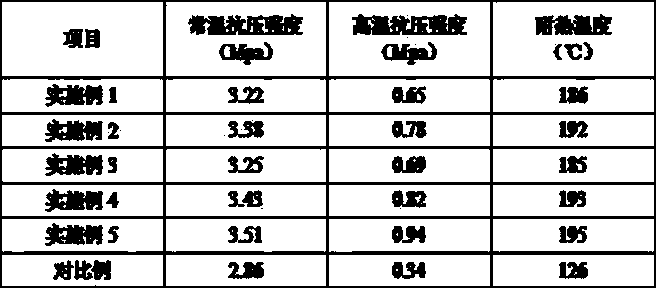

Examples

Embodiment 1

[0018] A binder for castings, which consists of the following components in parts by weight: 40 parts of furfuryl alcohol resin, 25 parts of bisphenol A epoxy resin, 13 parts of hydroxyethyl methylcellulose, ethylene glycol di 9 parts of acetate, 6 parts of diethyl aminomalonate, 16 parts of diluent, 2 parts of palm oil, 3 parts of magnesium oxide, 5 parts of antimony trioxide, 5 parts of sodium peroxide, 10 parts of absolute ethanol and 8 parts of ionized water.

[0019] The diluent is 1,6-hexanediol diglycidyl ether.

[0020] The above-mentioned preparation method of a casting binder, the preparation steps are as follows:

[0021] Step 1: Put furfuryl alcohol resin, bisphenol A type epoxy resin and diluent in the reaction kettle and stir and mix. The temperature of the reaction kettle is set at 40°C;

[0022] Step 2: then add ethylene glycol diacetate and diethyl aminomalonate successively and continue stirring;

[0023] Step 3: Then add palm oil and keep stirring to mix ...

Embodiment 2

[0026] A binder for castings, which consists of the following components in parts by weight: 60 parts of furfuryl alcohol resin, 42 parts of bisphenol A epoxy resin, 20 parts of hydroxyethyl methylcellulose, ethylene glycol di 7 parts of acetate, 14 parts of diethyl aminomalonate, 24 parts of thinner, 4 parts of palm oil, 9 parts of magnesium oxide, 12 parts of antimony trioxide, 11 parts of sodium peroxide, 18 parts of absolute ethanol and 14 parts of ionized water.

[0027] The diluent is phenyl glycidyl ether.

[0028] The above-mentioned preparation method of a casting binder, the preparation steps are as follows:

[0029] Step 1: Put furfuryl alcohol resin, bisphenol A type epoxy resin and diluent in the reactor and stir and mix, and the temperature of the reactor is set at 55°C;

[0030] Step 2: then add ethylene glycol diacetate and diethyl aminomalonate successively and continue stirring;

[0031] Step 3: Then add palm oil and keep stirring to mix evenly;

[0032] ...

Embodiment 3

[0034] A binder for castings, which consists of the following components in parts by weight: 50 parts of furfuryl alcohol resin, 34 parts of bisphenol A epoxy resin, 16 parts of hydroxyethyl methylcellulose, ethylene glycol di 13 parts of acetate, 10 parts of diethyl aminomalonate, 20 parts of diluent, 3 parts of palm oil, 6 parts of magnesium oxide, 8 parts of antimony trioxide, 8 parts of sodium peroxide, 14 parts of absolute ethanol and 11 parts of ionized water.

[0035] The diluent is phenyl glycidyl ether.

[0036] The above-mentioned preparation method of a casting binder, the preparation steps are as follows:

[0037] Step 1: Put furfuryl alcohol resin, bisphenol A type epoxy resin and diluent in the reaction kettle and stir and mix. The temperature of the reaction kettle is set at 42°C;

[0038] Step 2: then add ethylene glycol diacetate and diethyl aminomalonate successively and continue stirring;

[0039] Step 3: Then add palm oil and keep stirring to mix evenly;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com