Method for producing fuel oils by hydrogenation after coal tar cleaning and phenol extraction and system thereof

A coal tar, clean technology, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of reducing catalyst activity and life, increasing equipment and pipeline corrosion, dispersing vulcanization system, etc., to achieve raw material utilization rate High, improved utilization, simple process effect

Active Publication Date: 2016-02-03

WUHUAN ENG

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the hydrogenation of the whole fraction of coal tar will convert the high value-added phenolic compounds in the tar into hydrocarbons and water, which reduces the added value on the one hand; on the other hand increases the hydrogen consumption, and the presence of water will also reduce the activity and life of the catalyst. and increased corrosion of equipment and pipelines

In addition, the process uses a water-soluble nickel phosphomolybdate catalyst, which has a large dispersion vulcanization system, complex equipment, and high energy consumption

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0038] The processing condition of table 2 embodiment 1,2,3,4

[0039]

[0040]

[0041] The resulting product yield distribution of table 3

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

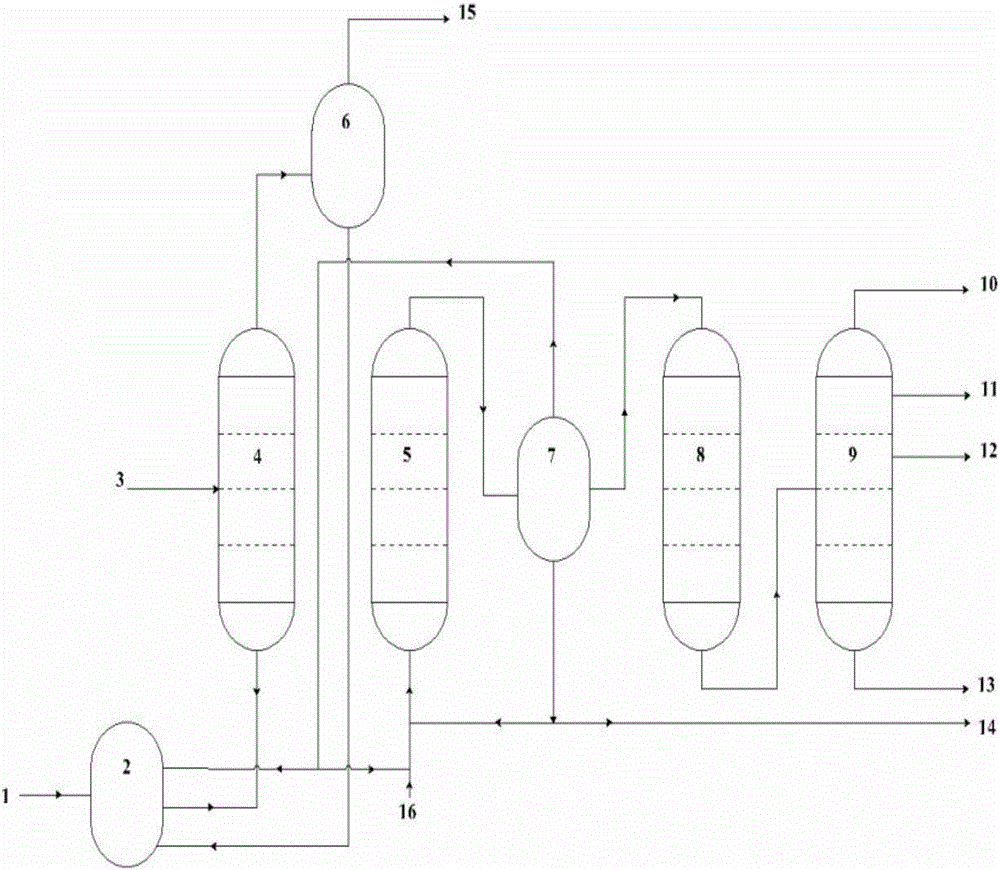

The invention relates to a method for producing fuel oils by hydrogenation after coal tar cleaning and phenol extraction and a system thereof. According to the technical scheme, coal tar is sent into a distillation column to separate a phenol-rich fraction and other fractions; dephenolized oil obtained after cleaning and phenol extraction of the phenol-rich fraction is used as solvent naphtha to be mixed with a catalyst and a vulcanizing agent, and the mixture is vulcanized to prepare catalyst slurry; the other fractions and the catalyst slurry are mixed and the mixture is sent into a slurry-bed hydrocracking reactor to undergo a hydrocracking reaction; reactants obtained after the hydrocracking reaction are then sent into a separation system to separate hydrogen-rich gas, light oil and tail oil containing a catalyst; the light oil is sent into a fixed-bed hydrogenation reactor to undergo a hydrofining reaction; and reactants obtained after the hydrofining reaction are sent into a fractionating tower to separate gaseous hydrocarbon, a gasoline fraction and a diesel fraction. The technology of the invention is simple; utilization rate of raw materials is high; the system is environmentally friendly, has low production cost and operating cost and is simple to maintain; service life of a catalyst is prolonged; and product yield is high.

Description

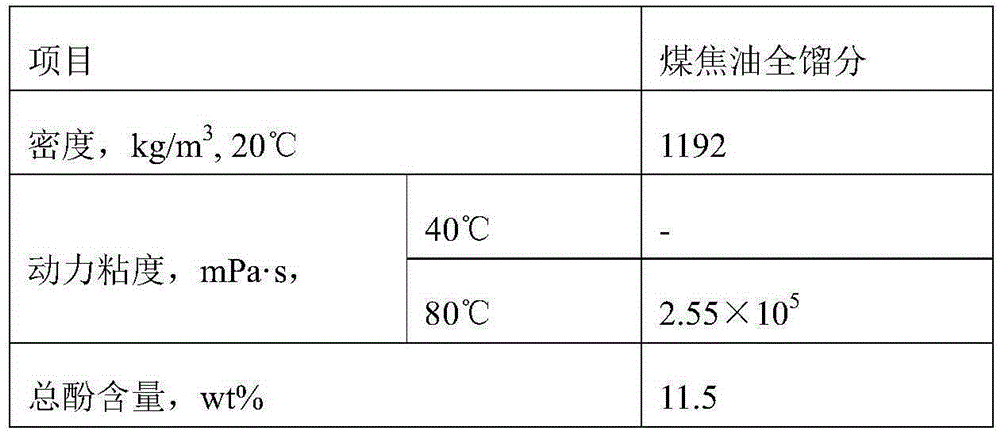

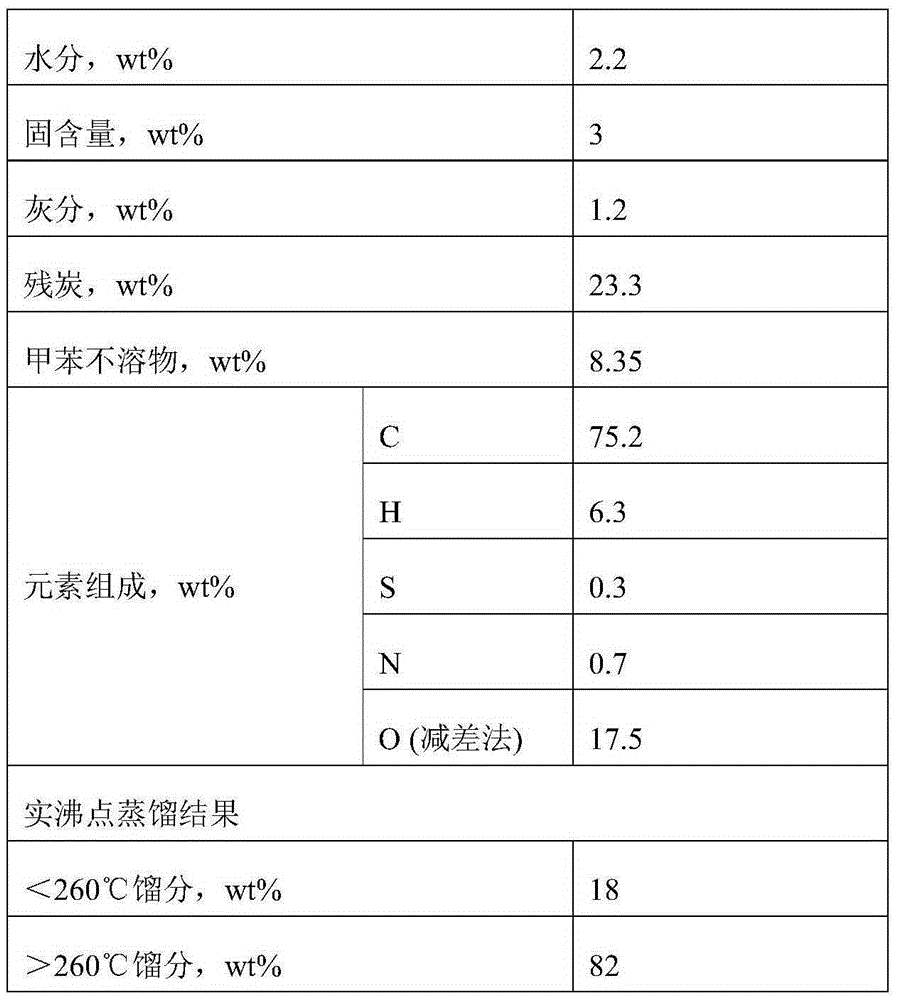

technical field [0001] The invention relates to a method and system for producing fuel oil, in particular to a method and system for producing fuel oil by hydrogenation after cleaning and extracting phenol from coal tar. Background technique [0002] With the rapid economic development, the market demand for light oil products is increasing day by day. Coal tar hydrogenation is an effective way to make it lighter and cleaner, and it is also the main direction of exploration for the processing and utilization of coal tar. Coal tar is a by-product of coal coking, carbonization and gasification. The whole fraction of coal tar is different from crude oil or heavy oil, its composition is complex, and the content of aromatics, colloids and asphaltenes is relatively high, especially the oxygen content is about 8wt%. Oxygen mainly exists in the form of phenolic and furanic compounds, and phenolic compounds are one of the basic raw materials of chemical industry with high added valu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G67/14

Inventor 王志刚卢文新陈风敬夏吴张大洲商宽祥

Owner WUHUAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com