Surface alloy strengthening method of aluminum-based piston ring grooves

A piston ring groove and surface alloy technology, which is applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of thin surface strengthening layer, complex process, environmental pollution, etc., and achieve low cost and high process efficiency. Simple operation and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1, determine the specific gravity of iron, nickel, chromium, tungsten, molybdenum and other elements, and mix the iron-based alloy powder (the content of nickel is 37%, the content of chromium is 15%, the content of molybdenum is 3%, and the rest is iron element) ;Dry and put into the powder feeder;

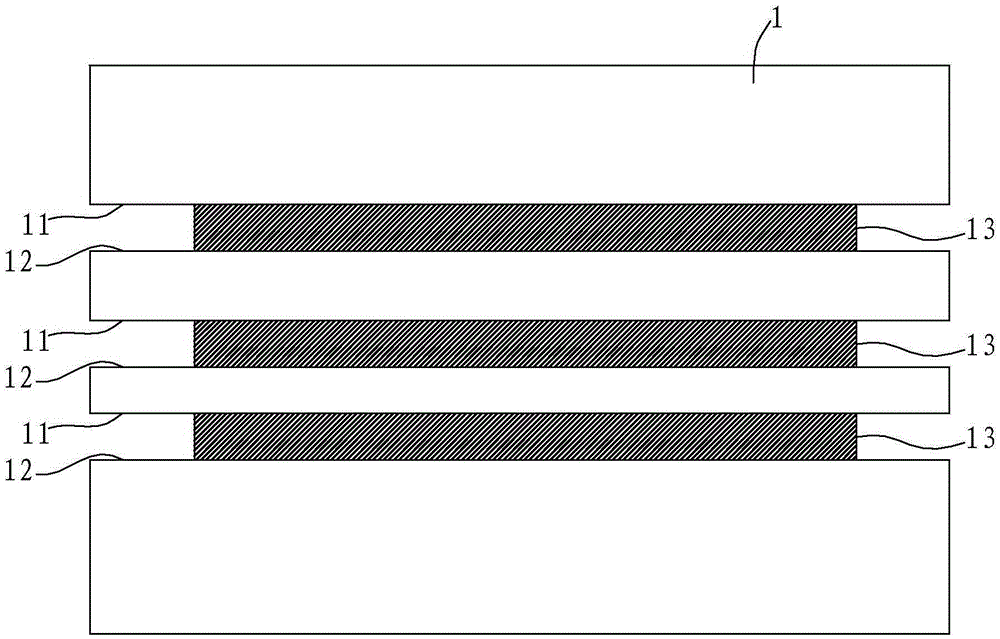

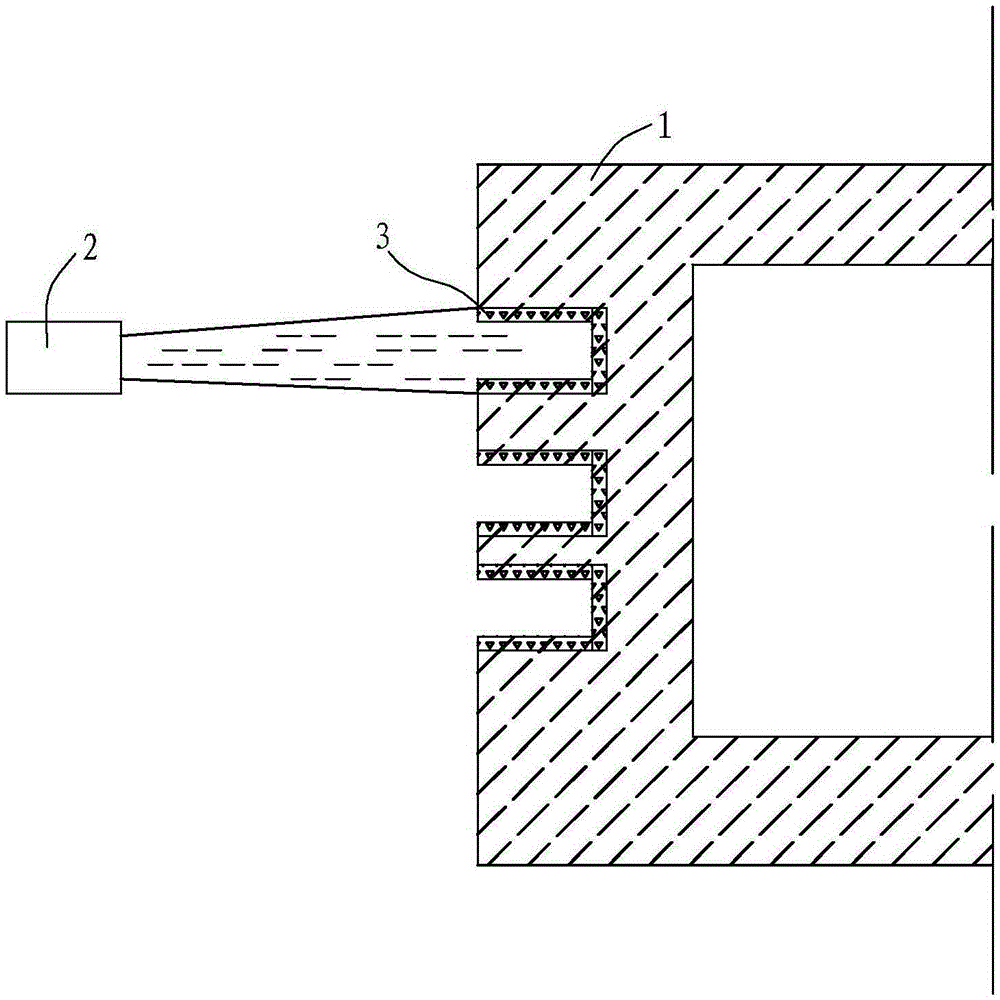

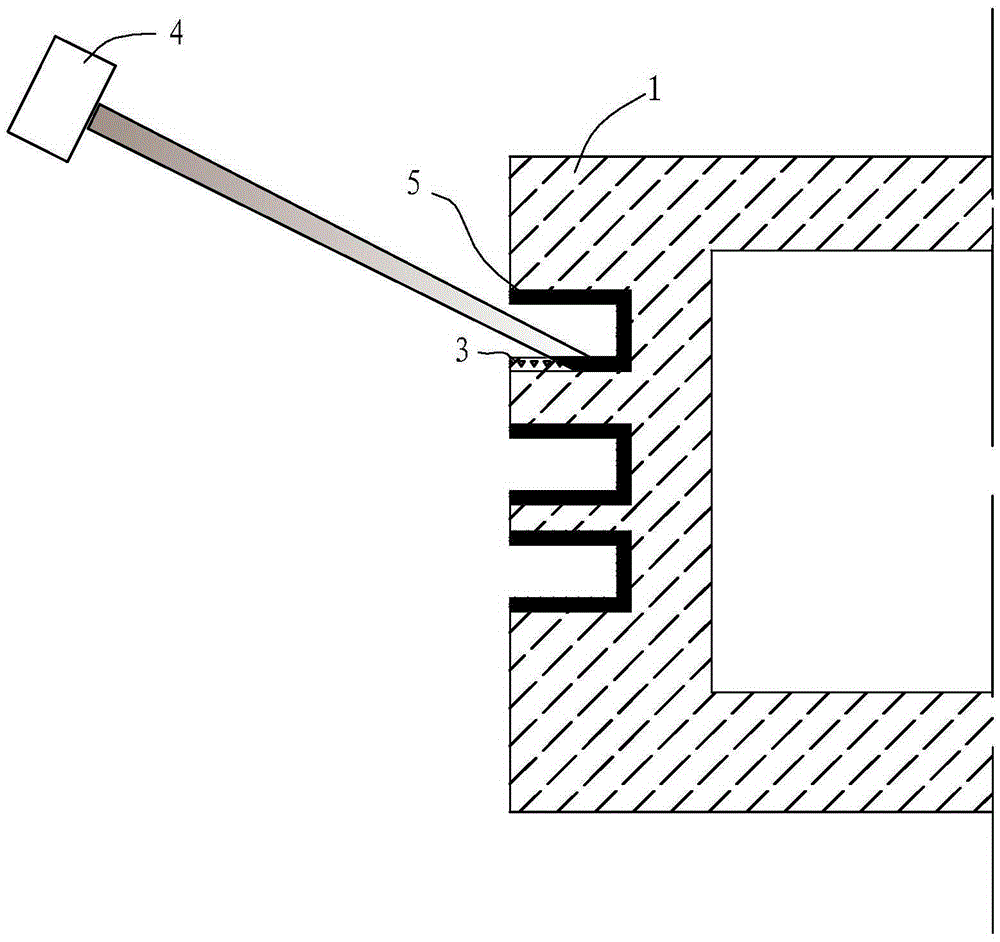

[0027] Step 2, use alcohol or kerosene to purify the upper, lower and inner surfaces of the aluminum-based piston ring groove to eliminate dirt and activate the surface; preheat the piston ring groove substrate to eliminate surface moisture and moisture, and improve the powder and The interface temperature when the surface of the ring groove is in contact can reduce the stress of the coating caused by the expansion of the substrate and avoid cracking of the coating. The aluminum-based piston head in the initial state is as figure 1 As shown, there are generally three ring grooves, the first and second are gas ring grooves, and the third is oil ring groove. Each annul...

Embodiment 2

[0035] Step 1, determine the specific gravity of iron, nickel, chromium, tungsten, molybdenum and other elements, and mix the iron-based alloy powder (the content of nickel is 37%, the content of chromium is 15%, the content of molybdenum is 3%, and the rest is iron element) ;Dry and put into the powder feeder;

[0036] Step 2, use alcohol or kerosene to purify the upper, lower and inner surfaces of the aluminum-based piston ring groove to eliminate dirt and activate the surface; preheat the piston ring groove substrate to eliminate surface moisture and moisture, and improve the powder and The interface temperature when the surface of the ring groove is in contact can reduce the stress of the coating caused by the expansion of the substrate and avoid cracking of the coating;

[0037] Step 3: Determine the plasma spraying process parameters according to the type of alloy powder, the structure of the ring groove and the performance of the spray gun. The voltage is controlled at ...

Embodiment 3

[0043]Step 1, determine the specific gravity of iron, nickel, chromium, tungsten, molybdenum and other elements, and mix the iron-based alloy powder (the content of nickel is 37%, the content of chromium is 15%, the content of molybdenum is 3%, and the rest is iron element) ;Dry and put into the powder feeder;

[0044] Step 2, use alcohol or kerosene to purify the upper, lower and inner surfaces of the aluminum-based piston ring groove to eliminate dirt and activate the surface; preheat the piston ring groove substrate to eliminate surface moisture and moisture, and improve the powder and The interface temperature when the surface of the ring groove is in contact can reduce the stress of the coating caused by the expansion of the substrate and avoid cracking of the coating;

[0045] Step 3: Determine the plasma spraying process parameters according to the type of alloy powder, the ring groove structure and the performance of the spray gun. The voltage is controlled at 85V, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com