Anti-oxidation coating for rhenium spray pipe, preparation method of anti-oxidation coating and rhenium-anti-oxidation coating spray pipe

An anti-oxidation coating and nozzle technology, applied in the coating, metal material coating process, gaseous chemical plating and other directions, can solve the coating thickness control, measurement and coating quality inspection difficult to achieve, deposition efficiency utilization rate It is not high, the deposition quality is difficult to control, etc., to achieve the effect of improving the structure and mechanical properties, controllable thickness uniformity, and uniform and controllable coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

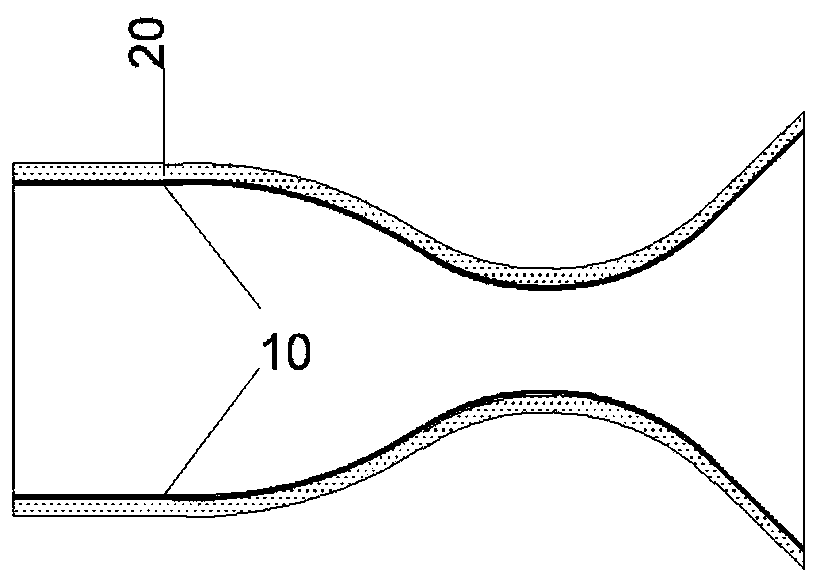

[0036] The invention provides a preparation method of an anti-oxidation coating for a rhenium nozzle, comprising the following steps:

[0037] Melting the iridium to obtain a cylindrical ingot;

[0038] Hot forging the cylindrical ingot to obtain a billet, the starting temperature of the hot forging is 1600-1800°C, the final forging temperature is 1400-1500°C, and the total processing deformation is not less than 60%;

[0039] performing surface treatment on the billet to remove impurities to obtain a treated billet;

[0040] Hot isostatic pressing is performed on the processed billet to obtain a bar. The conditions of the hot isostatic pressing are as follows: vacuumize and fill with argon, the temperature is 1500-1600°C, the pressure is 100-120MPa, the time for 2h;

[0041] The rod is machined to obtain the anti-oxidation coating for the rhenium nozzle.

[0042] In the invention, the iridium is smelted to obtain a cylindrical billet. The present invention has no special ...

Embodiment 1

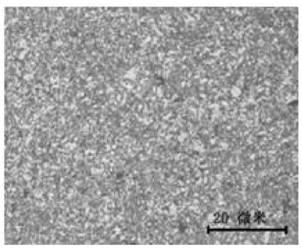

[0063] A preparation method for anti-oxidation coating (iridium-rhodium alloy coating) for rhenium nozzle, comprising the following steps:

[0064] (1) According to the composition of Ir-30Rh alloy, 150g of ingredients is distributed, and the ingredients are evenly divided into 5 parts, each of which is 30g. Use an electric arc furnace to melt each ingredient into a small ingot, put 5 small ingots in an intermediate frequency furnace for vacuum melting, and cast them into a Φ18mm cylindrical ingot;

[0065] (2) Put the Ir-30Rh alloy ingot into the high-temperature vacuum tungsten wire furnace, and the system is vacuumed to 2×10 -3 Pa starts to heat up, and then cools down after homogenizing heat treatment at a temperature of 1800°C for 2 hours;

[0066] (3) Put the Ir-30Rh alloy ingot into a magnesia crucible, use oxygen-acetylene to heat the ingot to 1700°C and start forging, use a circular die to carry out hot forging on the alloy ingot, when the temperature of the rod drop...

Embodiment 2

[0072] A preparation method for anti-oxidation coating (iridium-rhodium alloy coating) for rhenium nozzle, comprising the following steps:

[0073] (1) According to the composition of Ir-15Rh alloy, 1000g of ingredients is distributed, and the ingredients are evenly divided into 10 parts, each of which is 100g. Use an electric arc furnace to melt each ingredient into a small ingot, put 10 small ingots in an intermediate frequency furnace for vacuum melting, and cast them into a Φ46mm cylindrical ingot;

[0074] (2) Put the Ir-15Rh alloy ingot into a high-temperature vacuum tungsten wire furnace, and the system is vacuumed to 2×10 -3 Pa starts to heat up, and then cools down after homogenizing heat treatment at a temperature of 2000°C for 4 hours;

[0075] (3) Put the Ir-15Rh alloy ingot into a magnesia crucible, use oxygen-acetylene to heat the ingot to 1800°C, and start forging. Use a circular die to carry out hot forging on the alloy ingot. When the temperature of the rod d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com