Pretreatment device and method for wastewater before chemical oxygen demand detection

A chemical oxygen demand and pretreatment device technology, which is applied in the direction of analyzing the chemical reaction of the material, analyzing the material by observing the influence of the chemical indicator, and preparing the sample for the test. It can solve the problem of large measurement results, It cannot reflect the Fenton treatment effect, affects the accuracy of the measurement results, etc., and achieves the effects of improving accuracy, eliminating interference, and reducing the amount of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

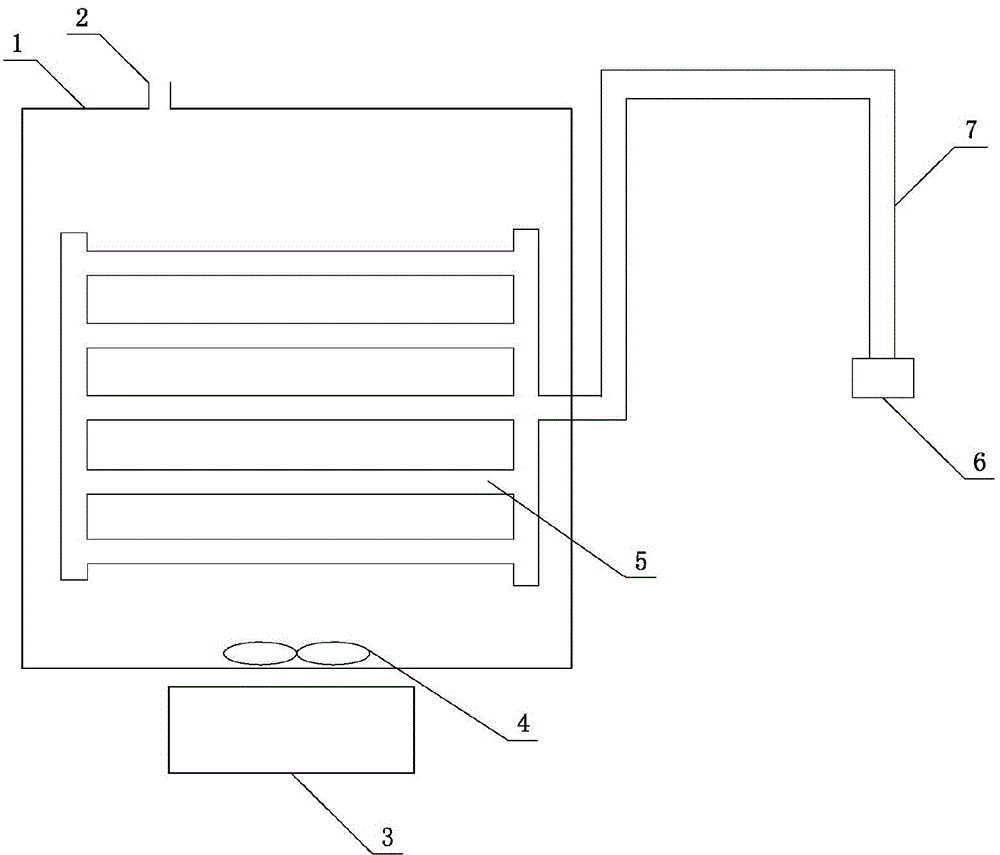

[0021] First, inject 2000mL of Fenton-treated wastewater into the reactor 1 through the exhaust port 2. According to the concentration of hydrogen peroxide before Fenton oxidation is 10mmol / L, the total amount of hydrogen peroxide before the reaction of this volume of water sample is calculated as 20mmol. Afterwards, the magnetic stirring device 3 is turned on, and the waste water is stirred by the magnetic rotor 4 .

[0022] Then, open the nitrogen monoxide intake system 6, the nitrogen monoxide substance quality contained in the aeration rate per minute is 2 times of the hydrogen peroxide substance quality before oxidation in the water sample, and the aeration pressure is 85% of the bubble point pressure, and the aeration Gas time lasts 3h.

[0023] Finally, close the nitric oxide intake system 6 and continue to maintain the stirring state for 10 minutes. Exhaust the residual gas, so that there is no residual hydrogen peroxide oxidant and nitric oxide reducing agent in the ...

Embodiment 2

[0025] First, inject 2000mL of Fenton-treated wastewater into the reactor 1 through the exhaust port 2. The concentration of hydrogen peroxide before Fenton oxidation is 10mmol / L, and the total amount of hydrogen peroxide before the reaction of this volume of water sample is calculated to be 20mmol. Secondly, the magnetic stirring device 3 is turned on so that the wastewater is in a stirred state. Then open the nitrogen monoxide intake system 6, the nitrogen monoxide substance quality contained in the aeration rate per minute is 3.5 times of the hydrogen peroxide substance quality before oxidation in the water sample, and the aeration pressure is 90% of the bubble point pressure, and the aeration Gas time lasts 4h. Finally, turn off the nitrogen monoxide intake system 6, continue to stir for 20 minutes, and then take samples for the potassium dichromate method to determine the chemical oxygen demand (COD). cr determination.

Embodiment 3

[0027] First, inject 2000mL of Fenton-treated wastewater into the reactor 1 through the exhaust port 2. The concentration of hydrogen peroxide before Fenton oxidation is 10mmol / L, and the total amount of hydrogen peroxide before the reaction of this volume of water sample is calculated to be 20mmol. Secondly, the magnetic stirring device 3 is turned on so that the wastewater is in a stirring state. Then, open the nitric oxide intake system 6, the nitric oxide substance quality contained in the aeration rate per minute is 5 times of the hydrogen peroxide substance quality before oxidation in the water sample, and the aeration pressure is 95% of the bubble point pressure. Gas time lasts 6h. Finally, turn off the nitrogen monoxide intake system 6, and continue to maintain the state of stirring for 30 minutes, and then take samples for the potassium dichromate method to determine the chemical oxygen demand (COD). cr determination.

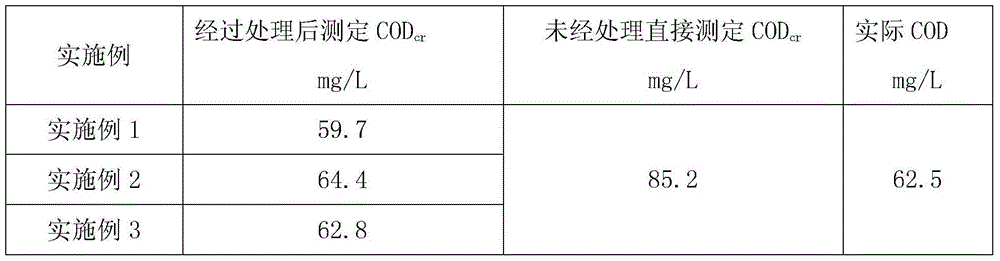

[0028] COD was carried out on the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com