Nickel-carbonate-doped manganese-carbonate-based anode material for lithium ion battery and preparation method

A negative electrode material, lithium ion technology, used in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor conductivity, low capacity retention, and large lithium ion transmission resistance, and achieve improved conductivity, capacity, and maintenance. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The manganese carbonate negative electrode material doped with nickel carbonate in this embodiment uses analytically pure raw materials, and the specific preparation steps are as follows.

[0041] (1) Mn(CH 3 COO) 2 , Ni(CH 3 COO) 2 , CO(NH 2 ) 2 Mix at a molar ratio of 100:5:210, then add 30mL deionized water and 30mL ethylene glycol;

[0042] (2) Put the substance in step (1) into a Teflon hydrothermal kettle and react at 160°C for 8h;

[0043] (3) The product in step (2) was centrifuged at 4500rpm, washed 3 times with deionized water and ethanol, and dried in vacuum for 12 hours;

[0044] (4) The product in step (3) and acetylene black, N,N-dimethylformamide (abbreviated as NMP) containing 5% polyvinylidene fluoride are mixed into mud with a mass ratio of 7:2:1 and then applied on the On the copper foil, the pole piece is obtained;

[0045] (5) Dry the pole piece obtained in step (4) in an oven to evaporate the NMP organic solvent.

[0046] The final product...

Embodiment 2-5

[0050] Using the same method as in Example 1, the only difference is that Mn(CH 3 COO) 2 , Ni(CH 3 COO) 2 , CO(NH 2 ) 2 Use the ratio shown in Table 1 to add.

[0051] Table 1

[0052]

Mn(CH 3 COO) 2

Ni(CH 3 COO) 2

CO(NH 2 ) 2

Example 2

100

10

220

Example 3

100

15

230

Example 4

100

20

240

Example 5

100

25

250

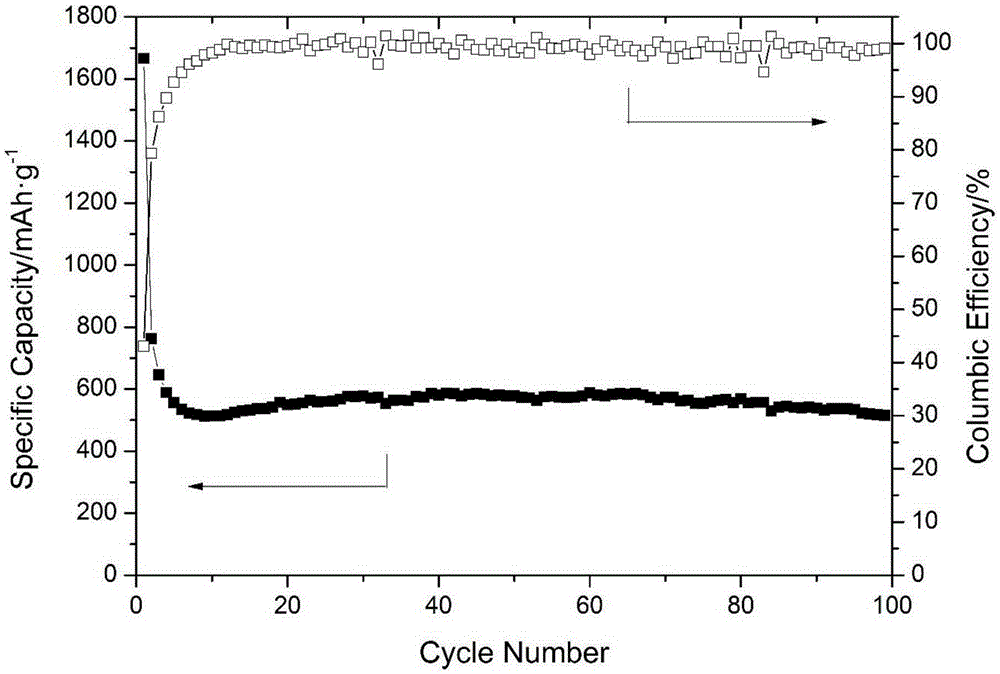

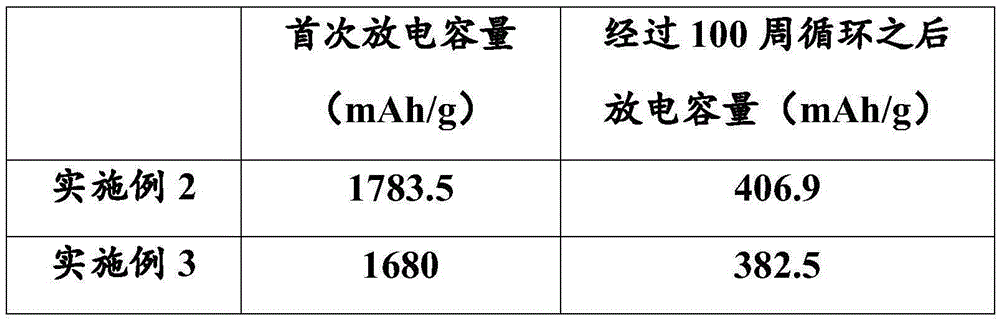

[0053] The performance curves of the manganese carbonate-based negative electrode material half-cell doped with nickel carbonate for the lithium ion secondary battery of Examples 2-5 were cycled to 100 cycles, and the results are shown in Table 2.

[0054] Table 2

[0055]

[0056]

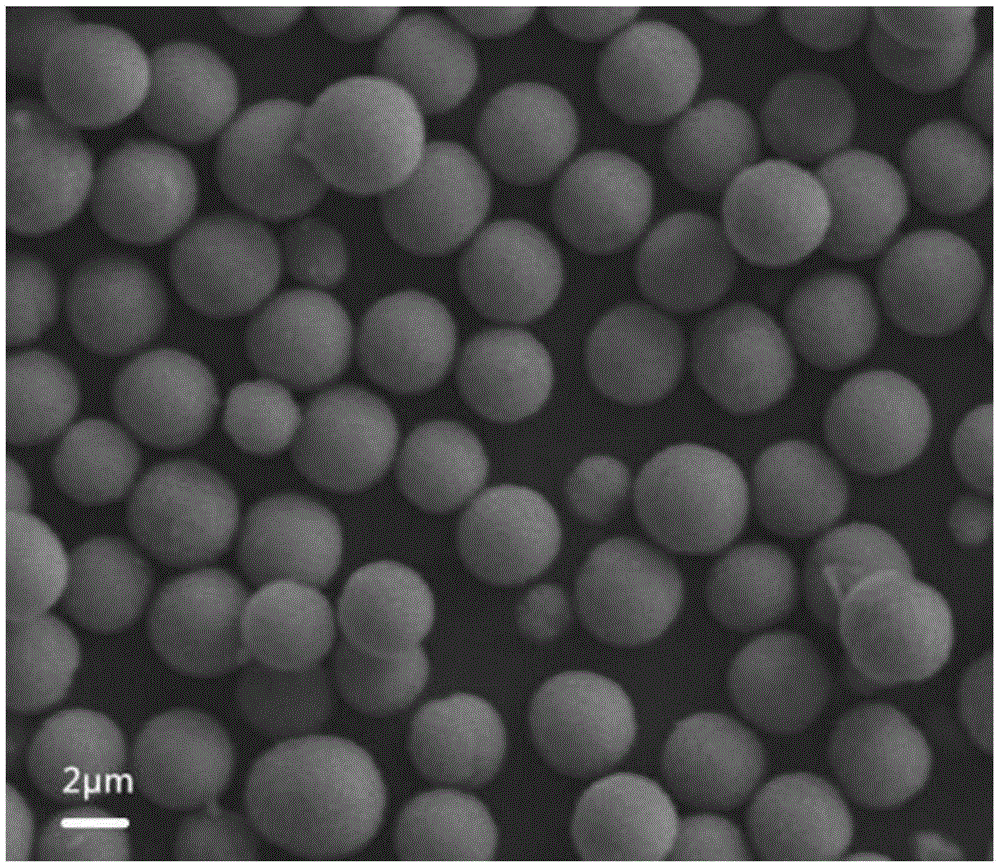

[0057] The SEM figure and figure 2 Similarly, the material is uniform in size and well distributed.

[0058] Embodiment 6-8 adopts the method identical with embodiment 1, and its difference is only that reaction time adopts the time reaction shown in table 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com