Photochromic curable composition

A curable composition, photochromic technology, applied in the direction of color-changing fluorescent materials, optics, optical components, etc., can solve the problems of large absorption of thick film, difficult application, no thickness of photochromic layer, etc., and achieve fast fading speed , The effect of high color concentration and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0439] Hereinafter, the present invention will be described in detail using examples and comparative examples, but the present invention is not limited to these examples. The abbreviations and names of the compounds used are shown below.

[0440] (A) polymerizable monomer component:

[0441] (X) (meth)acrylic polymerizable monomer

[0442] Multifunctional monomer (Xp)

[0443] (Xp-1)2 functional monomer

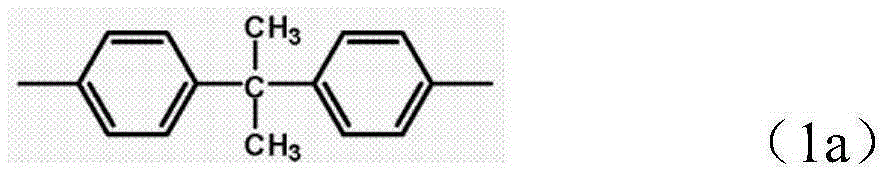

[0444] BPE100: 2,2-bis(4-methacryloyloxypolyethoxyphenyl)propane (the average repeating number of ethyleneoxy groups is 2.6, and the average molecular weight is 478)

[0445] BPE500: 2,2-bis(4-methacryloyloxypolyethoxyphenyl) 25 propane (the average repeating number of ethyleneoxy is 10, and the average molecular weight is 804)

[0446] 3G: Triethylene glycol dimethacrylate

[0447] 9G: Polyethylene glycol dimethacrylate (the average repeating number of ethyleneoxy groups is 9, and the average molecular weight is 536)

[0448] 14G: Polyethylene glycol dimethacrylate (th...

Embodiment 2~19

[0594] Using the polymerizable monomer component (A) described in Tables 1 and 2, and the compositions and plastic lens substrates shown in Tables 3 and 4, except that, the same procedure as in Example 1 was used to prepare photochromic curable Composition and make photochromic laminated body, carry out evaluation. The evaluation results are shown in Table 5.

[0595] [Table 1]

[0596]

[0597] [Table 2]

[0598]

[0599] [table 3]

[0600]

[0601] [Table 4]

[0602]

[0603] [table 5]

[0604]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com