Nuclear pore membrane ultraviolet light sensitization device and method

A nuclear pore membrane and ultraviolet light technology, which is applied in the field of nuclear pore membrane batch sensitization devices, can solve the problems of low production efficiency, different pore sizes on the upper and lower surfaces, and pore annealing, etc., to achieve high energy conversion efficiency and reduce sensitivity. The effect of reducing differences and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

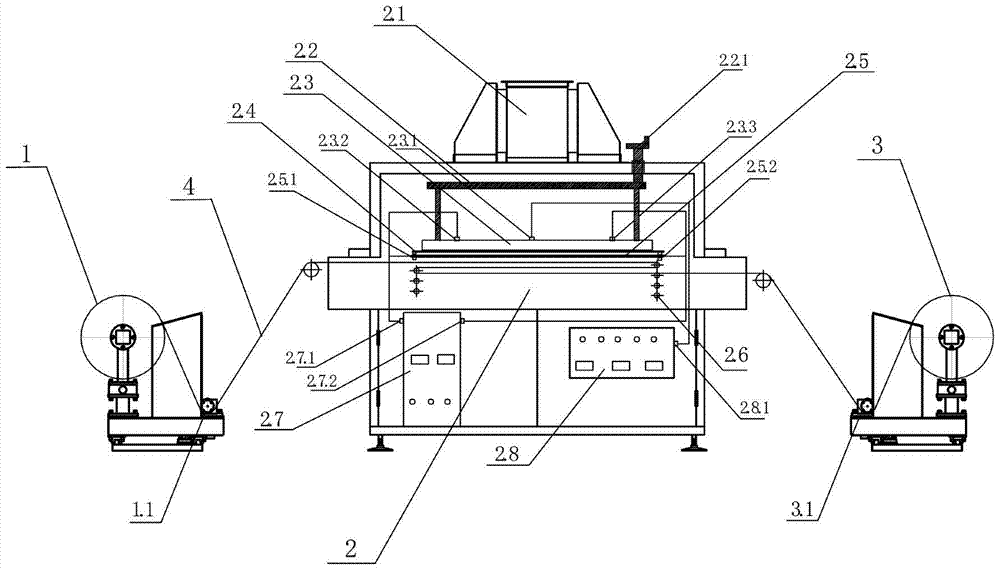

[0025] Embodiment 1: a nuclear pore membrane ultraviolet light sensitization device, its main feature is to include unwinder 1, ultraviolet sensitization machine 2 and winder 3; The rolling pressure roller 1.1, the sensitizing pressure roller 2.6 provided on the ultraviolet sensitization machine 2 and the winding pressure roller 3.1 provided on the winding machine 3 pass through the unwinding machine 1, the ultraviolet sensitizing machine 2 and the winding machine in sequence 3. The ultraviolet sensitization machine 2 includes a lifting adjustment bracket 2.2 under the fan 2.1, an ultraviolet LED surface light source 2.3, a heat insulating glass 2.4 on the lifting adjustment bracket 2.2, and a cooling water tank 2.5 under the heat insulating glass 2.4 The sensitizing pressure roller 2.6 is located below the cooling water tank 2.5, the cooling water tank 2.7 communicates with the cooling water tank 2.5; the power control box 2.8 is electrically connected with the ultraviolet LED...

Embodiment 2

[0033] Example 2: see figure 1 , a nuclear pore membrane ultraviolet light sensitization device, the device includes an unwinder 1, an ultraviolet sensitizer 2 and a winder 3 three parts. The nuclear pore membrane passes through the unwinding machine 1, the ultraviolet sensitizing machine 2 and the winding machine 3 in sequence by using the unwinding pressure roller 1.1, the sensitizing pressure roller 2.6 and the winding pressure roller 3.1. The ultraviolet sensitization machine is equipped with fan 2.1, lifting adjustment bracket 2.2, ultraviolet LED surface light source 2.3, heat insulating glass 2.4, cooling water tank 2.5, sensitizing roller 2.6, cooling water tank 2.7 and power control box 2.8 from top to bottom. The light emitted by the ultraviolet LED surface light source 2.3 passes through the heat insulating glass 2.4 and the cooling water tank 2.5 in turn for cold treatment, and then irradiates and penetrates the multilayer nuclear pore membrane. The cooling water...

Embodiment 3

[0039] Embodiment 3: see figure 1 , a nuclear pore membrane ultraviolet light sensitization device, the device includes an unwinder 1, an ultraviolet sensitizer 2 and a winder 3 three parts. The nuclear pore membrane passes through the unwinding machine 1, the ultraviolet sensitizing machine 2 and the winding machine 3 in sequence by using the unwinding pressure roller 1.1, the sensitizing pressure roller 2.6 and the winding pressure roller 3.1. The ultraviolet sensitization machine is equipped with fan 2.1, lifting adjustment bracket 2.2, ultraviolet LED surface light source 2.3, heat insulating glass 2.4, cooling water tank 2.5, sensitizing roller 2.6, cooling water tank 2.7 and power control box 2.8 from top to bottom. The light emitted by the ultraviolet LED surface light source 2.3 passes through the heat insulating glass 2.4 and the cooling water tank 2.5 in turn for cold treatment, and then irradiates and penetrates the multilayer nuclear pore membrane. The cooling wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com