Preparation method of high-performance suspension PTFE

A PTFE, high-performance technology, applied in the field of preparation of high-performance suspended PTFE, can solve the problems affecting the performance of PTFE, low PTFE yield, prone to side reactions, etc., to achieve less side reactions, high yield, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

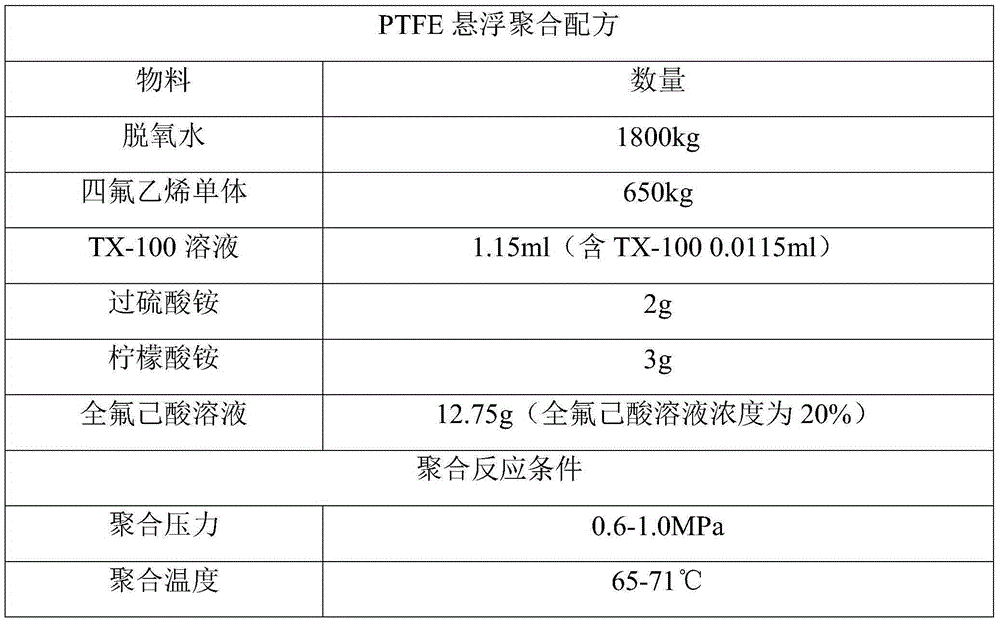

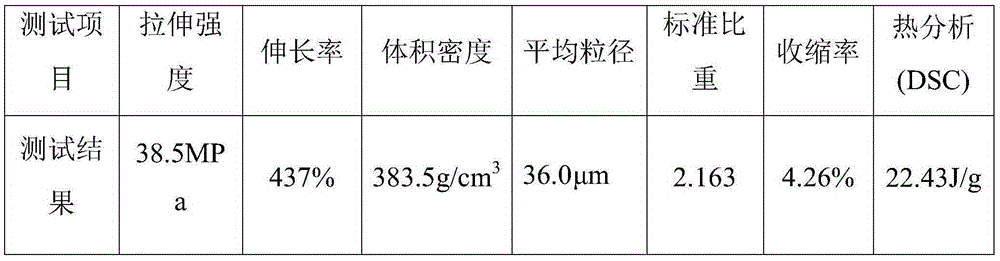

[0026] The invention provides a kind of preparation method of high-performance suspension PTFE, specifically comprises the following steps:

[0027] (1) Leak checking of the polymerization kettle: first empty the polymerization kettle, close all valves of the polymerization kettle, open the nitrogen manual valve of the polymerization kettle, pressurize the polymerization kettle to 1600kPa, check whether the polymerization kettle is leaking, and pass through the polymerization kettle. Then proceed to the next process; if the polymerization kettle is found to be leaking, the problem of air leakage should be dealt with in time, and the next process can only be carried out after the polymerization kettle does not leak. The pressure charging method is used to detect whether the polymerization kettle is leaking. The leak detection method is simple and easy to operate. It can detect the leakage of the polymerization kettle in time and improve the safety of the full formula reaction op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com