Method for determining quality of chromium oxide coating in chromium electroplated plate

A chromium oxide and determination method technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as complex operation, high investment cost, long measurement time, etc., meet the detection requirements, and measure quickly and easily , the effect of good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

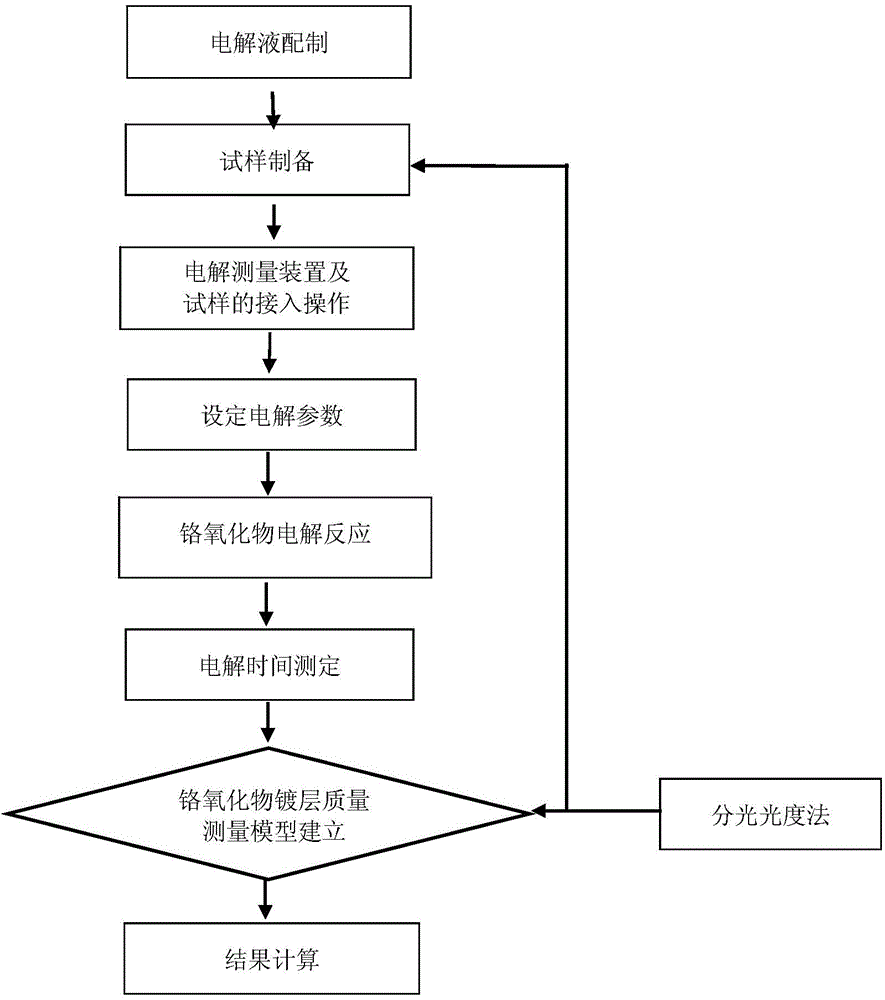

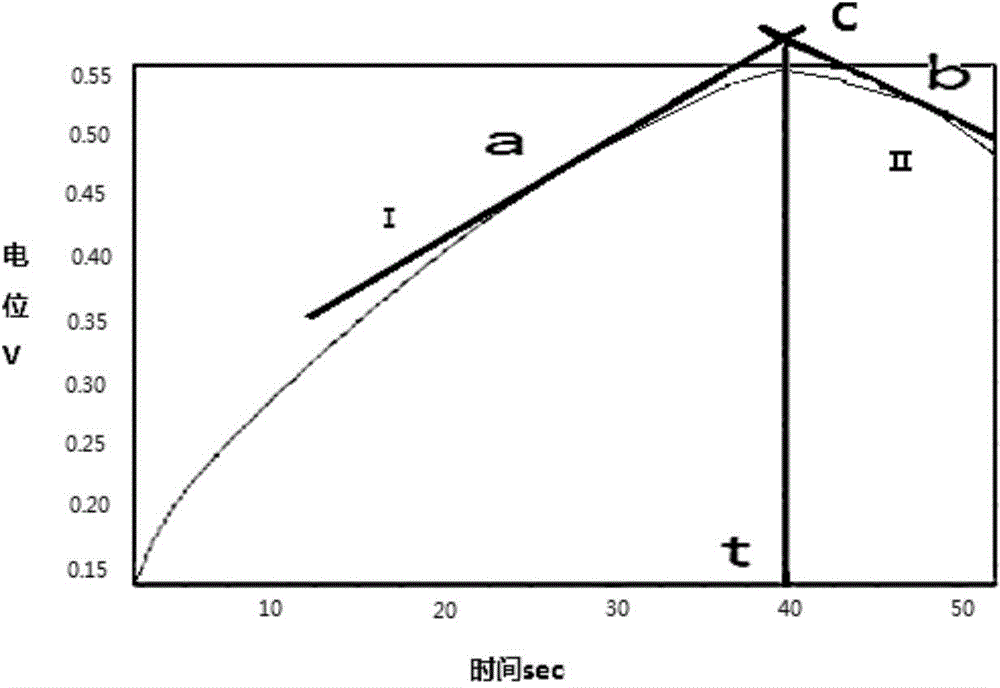

Method used

Image

Examples

Embodiment 1

[0048] 1. Electrolyte preparation: weigh 7.6 grams of Na 2 HPO 4 2H 2 O and 1.85 g NaH 2 PO 4 2H 2 O, placed in 1 liter of distilled water, the pH value of this electrolyte is about 7.1;

[0049] 2. Sample preparation: Punch a disc sample with a diameter of 57.3 mm from the operation side, middle part and transmission side of the sample plate width, such as Figure 4 Shown; use absolute ethanol to remove the oil film on the surface of the sample.

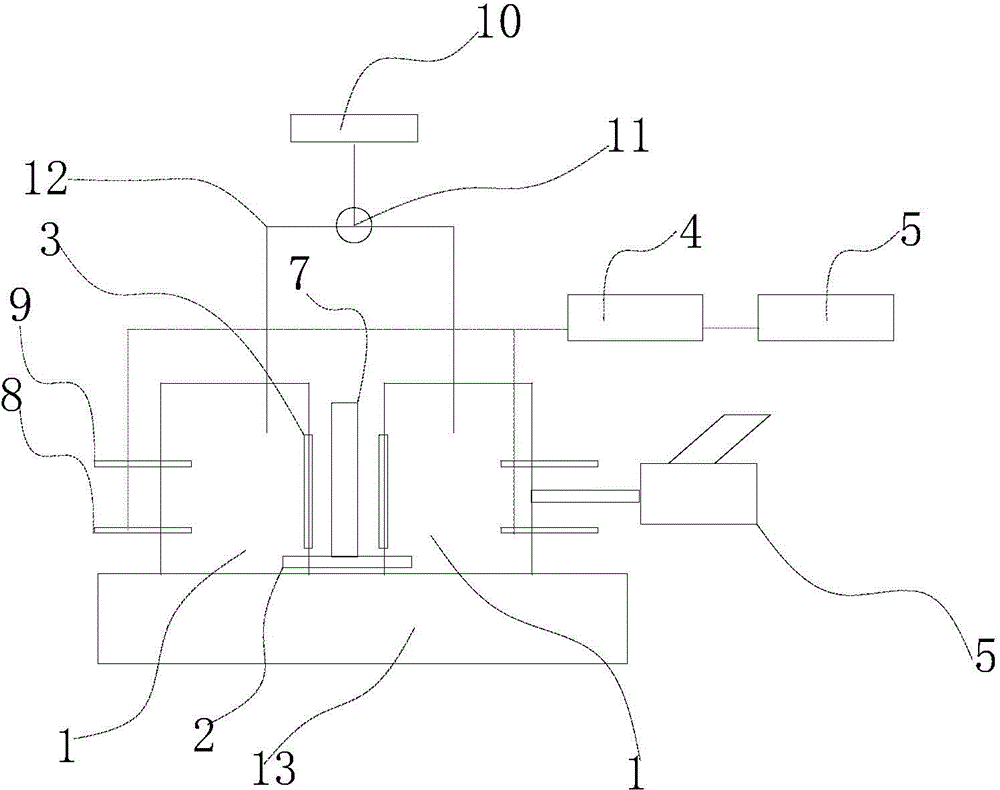

[0050] 3. Access operation of electrolytic measuring device and sample

[0051] 3.1 Put the sample into the electrolytic cell, close the push rod 6, and close the electrolytic cell.

[0052] 3.2 Two electrolytic cells are used, which are spliced by two electrolytic cells 1 through connecting rods 2, and can simultaneously measure the quality of the chromium oxide coating on the front and back sides of the sample.

[0053] 3.3 The sample is closed by the sealing ring 3, and the closed area is the electrolysis area of the ...

Embodiment 2

[0078] 1. Electrolyte preparation: 15.3 grams of Na 2 HPO 4 12H 2 O is dissolved in 1 liter of distilled water, and then its acidity is adjusted to be PH=7 with 10wt% sodium hydroxide solution, and this solution is the electrolytic solution of the chromium oxide coating of the electrochrome plate.

[0079] 2. Sample preparation: Punch a disc sample with a diameter of 57.3 mm from the operation side, middle part and transmission side of the sample plate width, such as Figure 4 As shown, absolute ethanol was used to remove the oil film on the surface of the sample.

[0080] 3. Access operation of electrolytic measuring device and sample

[0081] 3.1 Put the sample into the electrolytic cell, close the push rod 6, and close the electrolytic cell.

[0082] 3.2 Two electrolytic cells are used, which are spliced by two electrolytic cells 1 through connecting rods 2, and can simultaneously measure the quality of the chromium oxide coating on the front and back sides of the sam...

Embodiment 3

[0108] 1. Electrolyte preparation: weigh 7.6 grams of Na 2 HPO 4 2H 2 O and 1.85 g NaH 2 PO 4 2H 2 O, placed in 1 liter of distilled water, the pH value of this electrolyte is about 7.1.

[0109] 2. Sample preparation: Punch a disc sample with a diameter of 57.3 mm from the operation side, middle part and transmission side of the sample plate width, such as Figure 4 shown. The oil film on the surface of the sample was removed with absolute ethanol.

[0110] 3. Access operation of electrolytic measuring device and sample

[0111] 3.1 Put the sample into the electrolytic cell, close the push rod 6, and close the electrolytic cell.

[0112] 3.2 Use one electrolytic cell 1 and replace another electrolytic cell with a fixed plate to measure the quality of the chromium oxide coating on the electrochrome plated plate on one side of the sample.

[0113] 3.3 The sample is closed by the sealing ring 3, and the closed area is the electrolysis area of the sample.

[0114] 3.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com