Method for efficiently removing chemical groups from surface of supercapacitor carbon and supercapacitor carbon

A surface chemical and capacitive carbon technology, applied in the field of surface chemical group elimination, can solve the problems of unstable electrochemical performance, fast capacitance decay, short service life, etc., and achieve easy scale promotion, low capacitance decay, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

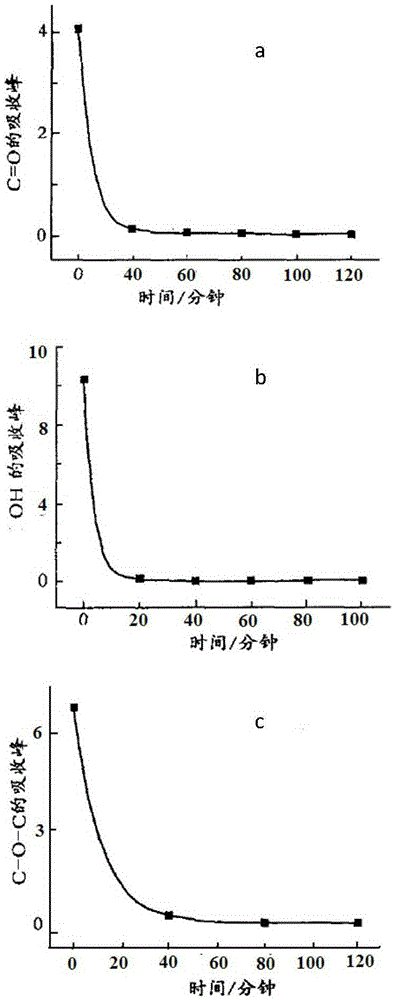

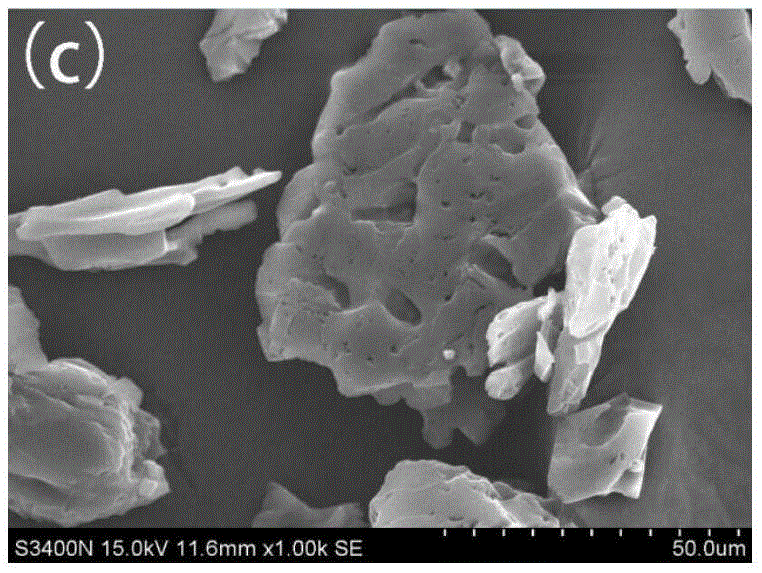

[0029] The first step is to weigh a certain amount of supercapacitor carbon powder, the particle diameter is less than 15 microns, and it is miscible in distilled water. The mass ratio of carbon to water is kept at 1:20, and placed in a constant temperature magnetic stirrer with a stirring speed of 2000r / min. Keep the charcoal powder fully suspended.

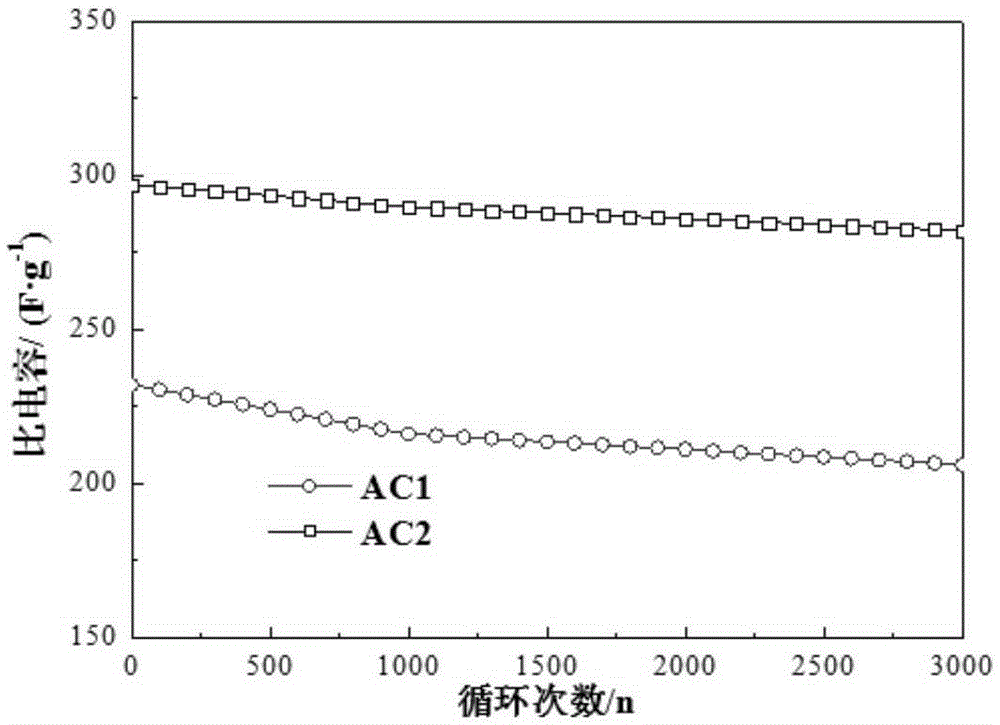

[0030] In the second step, according to the mass ratio of carbon to hydrazine hydrate of 1:0.5, add hydrazine hydrate dropwise to the suspension, keep the temperature of the water bath at 60°C, react for 30 minutes, and keep magnetic stirring to suspend the carbon powder. After the reaction, the carbon powder was filtered, and the carbon powder was rinsed with distilled water for 3 times. The filtered sample was placed in an oven at 105°C and taken out after 3 hours to obtain a supercapacitor carbon with surface functional groups eliminated. The supercapacitor carbon has 3000 charge and discharge cycles, the capacitance decay ra...

Embodiment 2

[0032] The first step is to weigh a certain amount of supercapacitor carbon powder, the particle diameter is less than 15 microns, and it is miscible in distilled water. The mass ratio of carbon to water is kept at 1:20, and placed in a constant temperature magnetic stirrer with a stirring speed of 2000r / min. Keep the charcoal powder fully suspended.

[0033] In the second step, according to the mass ratio of carbon to hydrazine hydrate of 1:1.0, add hydrazine hydrate dropwise to the suspension, keep the temperature of the water bath at 80°C, react for 60 minutes, and keep magnetic stirring to suspend the carbon powder. After the reaction, the carbon powder was filtered, and the carbon powder was rinsed with distilled water for 3 times. The filtered sample was placed in an oven at 105°C and taken out after 3 hours to obtain a supercapacitor carbon with surface functional groups eliminated. The supercapacitor carbon was prepared for 3000 charge and discharge cycles, the capacit...

Embodiment 3

[0035] The first step is to weigh a certain amount of supercapacitor carbon powder, the particle diameter is less than 15 microns, and it is miscible in distilled water. The mass ratio of carbon to water is kept at 1:20, and placed in a constant temperature magnetic stirrer with a stirring speed of 2000r / min. Keep the charcoal powder fully suspended.

[0036] In the second step, according to the mass ratio of carbon to hydrazine hydrate of 1:2.0, add hydrazine hydrate dropwise to the suspension, keep the temperature of the water bath at 90°C, react for 90 minutes, and keep magnetic stirring to suspend the carbon powder. After the reaction, the carbon powder was filtered, and the carbon powder was rinsed with distilled water for 3 times. The filtered sample was placed in an oven at 105°C and taken out after 3 hours to obtain a supercapacitor carbon with surface functional groups eliminated. It is characterized in that the prepared supercapacitor carbon has 3000 charging and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com