Method for adsorbing and degrading perfluorinated compounds in water

A technology for activating products and water bodies, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve problems such as poor adsorption effect and unresolved PFCs treatment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation steps of the reactivated activated carbon are as follows: 3 g of activated carbon is added to 20 mL of KOH solution, wherein the mass of KOH is 3 g. After two days of impregnation, the material was dried in an oven at 105°C for 8 hours. The dried material was placed in a tube furnace for activation. The activation procedure was as follows: first, the temperature was raised to 500 °C at a rate of 10 °C / min, and then to 1000 °C at a rate of 5 °C / min. Keep at 1000°C for 1.5h, then cool to room temperature naturally. During the activation process, N was passed through the tube furnace all the time 2 Protect. The activated material is repeatedly washed with high-purity water until the pH of the cleaning solution is less than 8, and the cleaned material is dried at 105°C.

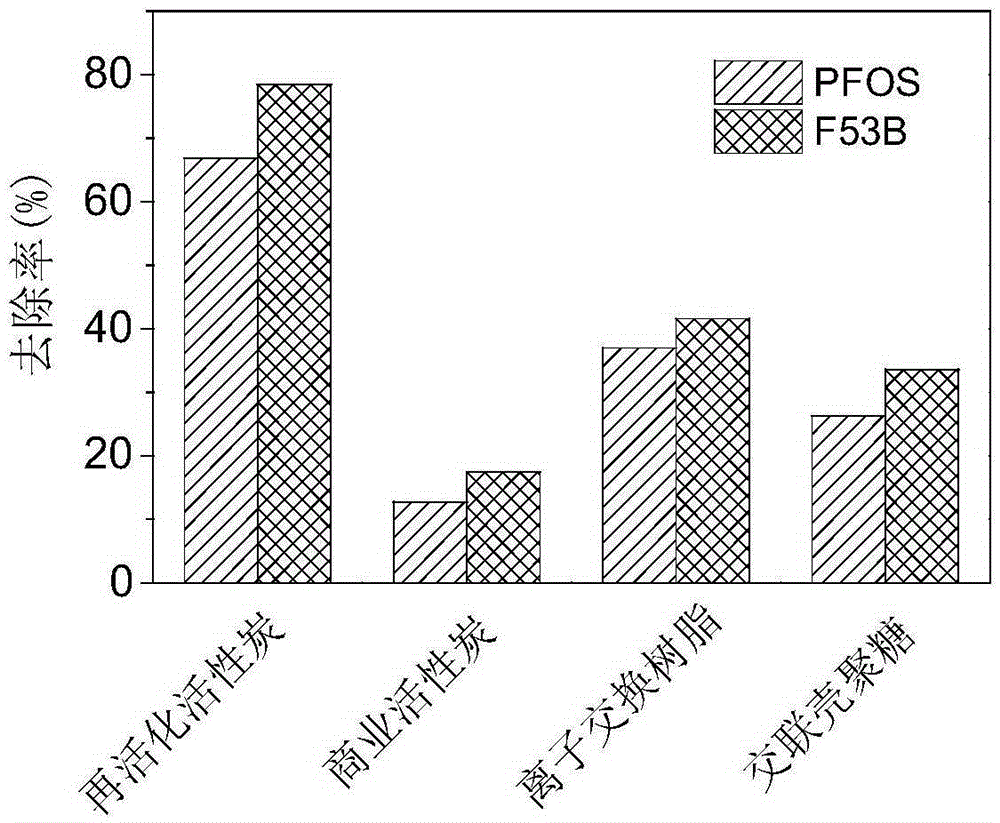

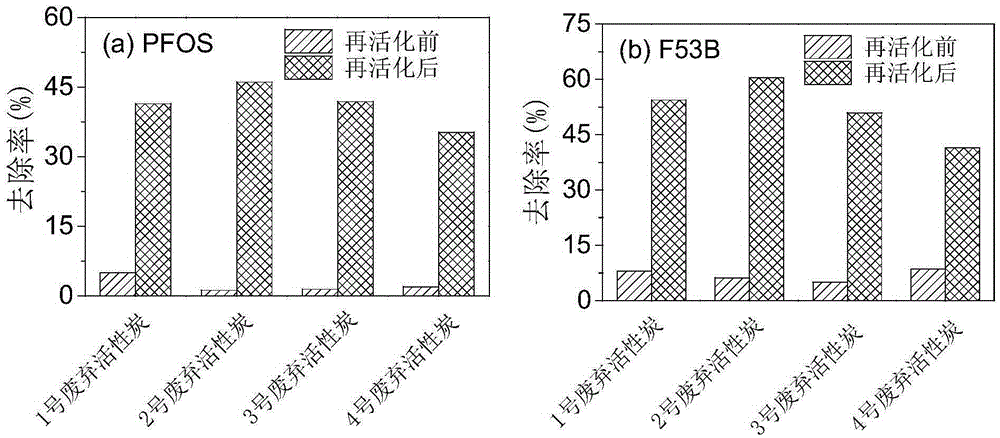

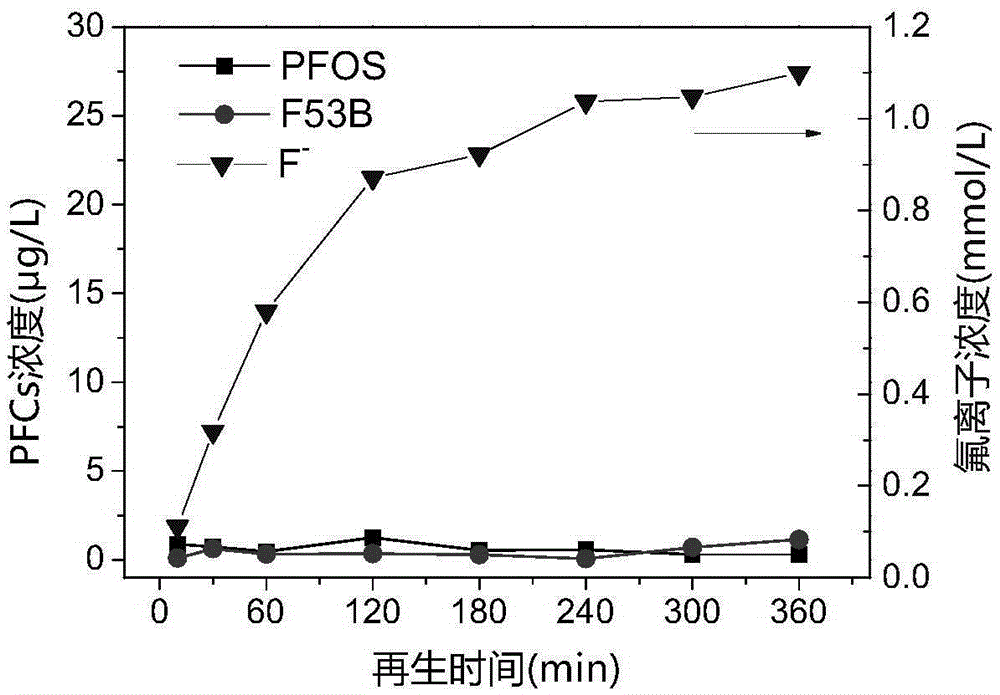

[0050] The experimental procedure for the removal of PFCs in chrome-plating sewage is as follows: 10mg of reactivated activated carbon, commercial activated carbon, IRA67 ion exchange re...

Embodiment 2

[0058] The preparation steps of reactivated activated carbon are as follows: 3 g of commercial coconut shell activated carbon is added to 20 mL of potassium bicarbonate solution, wherein the mass of potassium bicarbonate is 4 g. After two days of impregnation, the material was dried in an oven at 105°C for 8 hours. The dried material was placed in a tube furnace for activation. The activation procedure was as follows: first, the temperature was raised to 500 °C at a rate of 10 °C / min, and then to 1000 °C at a rate of 5 °C / min. Keep at 1000°C for 1.5h, then cool to room temperature naturally. During the activation process, N was passed through the tube furnace all the time 2 Protect. The activated material is repeatedly washed with high-purity water until the pH of the cleaning solution is less than 8, and the cleaned material is dried at 105°C.

[0059] The experimental procedure for the removal effect of PFCs in chrome-plating sewage is as follows: add 10 mg of reactivated...

Embodiment 3

[0062] The preparation steps of reactivated activated carbon are as follows: add 3 g of commercial coconut shell activated carbon into 20 mL of KOH solution, wherein the mass of KOH is 4.5 g. After two days of impregnation, the material was dried in an oven at 105°C for 8 hours. The dried material was placed in a tube furnace for activation. The activation procedure was as follows: first, the temperature was raised to 500 °C at a rate of 10 °C / min, and then to 1000 °C at a rate of 5 °C / min. Keep at 1000°C for 1.5h, then cool to room temperature naturally. During the activation process, N was passed through the tube furnace all the time 2 Protect. The activated material is repeatedly washed with high-purity water until the pH of the cleaning solution is less than 8, and the cleaned material is dried at 105°C.

[0063] The experimental procedure for the removal effect of PFCs in chrome-plating sewage is as follows: add 10 mg of reactivated activated carbon to chrome-plating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com