Method for processing high-concentration dibutyl phthalate-containing organic waste water

A technology of dibutyl phthalate and organic waste water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as rare reports and achieve resource recovery , the effect of reducing costs and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

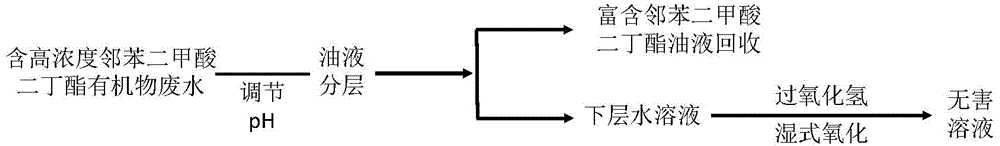

Image

Examples

Embodiment 1

[0044] The organic wastewater containing high-concentration dibutyl phthalate used in this example is the concentrated wastewater produced in the separation and purification step in the process of preparing BDO in a chemical fiber factory. The water quality characteristics are: pH is 1.7, and the mass content of DBP is 73 %, the COD concentration is as high as 1190000mg / L.

[0045] The experimental procedure of this embodiment:

[0046] 1) Add sodium hydroxide solution to the organic wastewater containing high concentration of dibutyl phthalate, adjust its pH value to 11, stir for 0.5h, store it statically for 1h and separate layers, the upper layer is dibutyl phthalate The mass content of the ester is an oil phase of 85.4%, the lower layer is an aqueous phase solution with a mass content of 5.84% dibutyl phthalate and other organic matter, the COD of the lower aqueous phase solution is 920000mg / L, the upper oil phase and the lower water phase The volume ratio of the phase so...

Embodiment 2

[0050] The organic wastewater containing high-concentration dibutyl phthalate used in this example is the concentrated wastewater produced in the separation and purification step in the process of preparing BDO in a chemical fiber factory. The water quality characteristics are: pH is 1.8, and the mass content of DBP is 75. %, the COD concentration is as high as 1300000mg / L.

[0051] The experimental procedure of this embodiment:

[0052] 1) Add sodium hydroxide solution to the organic wastewater containing high concentration of dibutyl phthalate, adjust its pH value to 10.5, stir for 0.5h, store statically for 0.5h and separate layers, the upper layer is dibutyl phthalate The mass content of butyl ester is an oil phase of 81.6%, the lower layer is an aqueous phase solution with a mass content of 5.23% dibutyl phthalate and other organic matter, the COD of the lower aqueous phase solution is 1000000mg / L, the upper oil phase and the lower The volume ratio of the aqueous phase s...

Embodiment 3

[0056] The organic wastewater containing high-concentration dibutyl phthalate used in this example is the concentrated wastewater produced in the separation and purification step in the process of preparing BDO in a chemical fiber factory. The water quality characteristics are: pH is 1.5, and the mass content of DBP is 72 %, COD concentration is 1000000mg / L.

[0057] The experimental procedure of this embodiment:

[0058] 1) Add sodium hydroxide solution to the organic wastewater containing high concentration of dibutyl phthalate, adjust its pH value to 10.2, stir for 0.5h, store it statically for 1h and separate layers, the upper layer is dibutyl phthalate The mass content of the ester is an oil phase of 80.16%, the lower layer is an aqueous phase solution with a mass content of 4.24% dibutyl phthalate and other organic matter, the COD of the lower aqueous phase solution is 800000mg / L, the upper oil phase and the lower water phase The volume ratio of the phase solution is 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com