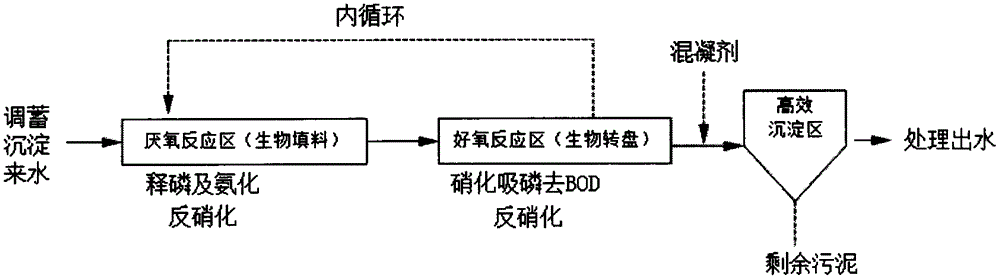

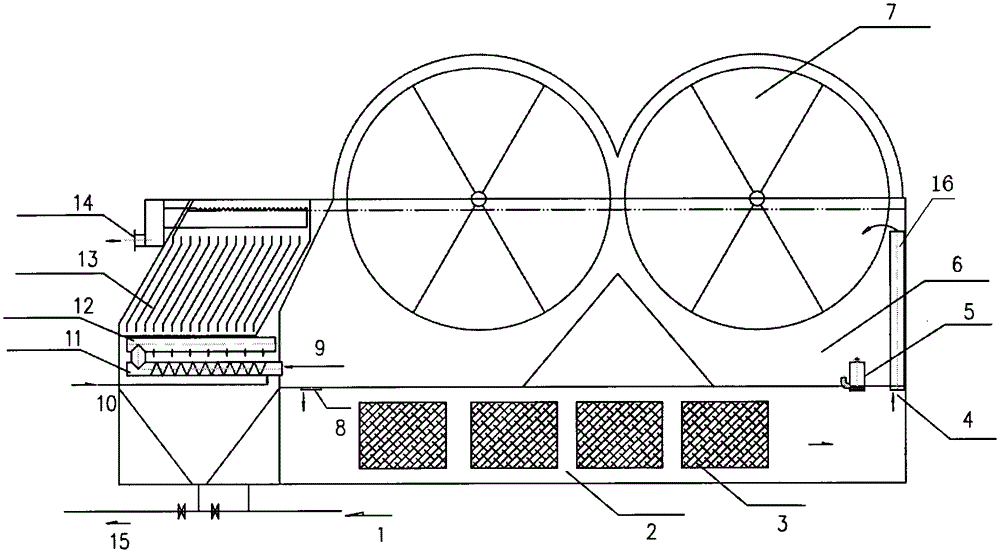

Method for treating domestic sewage through anaerobic-contact oxidation bio-membrane reactor and treatment device

A technology of biofilm reactor and contact oxidation, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Meet the requirements and other issues, achieve strong adaptability and operation stability, strengthen the efficiency of nitrogen and phosphorus removal, and strong impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method of the present invention is used to treat domestic sewage in a town. The raw sewage water quality: pH: 7.2, CODcr: 280mg / L, BOD5: 150mg / L, SS: 58mg / L, NH 4 + -N: 28mg / L, TP: 5.5mg / L.

[0039] Start the high-efficiency nitrogen and phosphorus removal mode of the internal circulation system:

[0040] 1) The collected township sewage is adjusted and stored in the high-level storage tank and pre-sedimented, forming a 3m water pressure difference with the reactor in the subsequent step 2).

[0041] 2) Control the pre-precipitated sewage in step 1) to enter the anaerobic-contact oxidation biofilm reactor through gravity flow. Sewage first enters the anaerobic reaction zone of the reactor. The anaerobic reaction zone is equipped with anaerobic biological packing for the attachment and growth of anaerobic microorganisms. The filling rate of the anaerobic biological packing in the anaerobic reaction zone is 80%, and the HRT is 6 hours. The anaerobic reaction zone The dissol...

Embodiment 2

[0048] Using the method of the present invention to treat domestic sewage in a certain township, the quality of sewage raw water: COD cr :160mg / L, BOD 5 :100mg / L, NH 4 + -N: 16mg / L, TP: 3mg / L.

[0049] It adopts ultra-low energy consumption operation mode, that is, does not start the internal circulation system.

[0050] 1) The collected township sewage is adjusted and stored in the high-level storage tank and pre-sedimented, forming a 1m water pressure difference with the reactor in the subsequent step 2).

[0051] 2) Control the pre-precipitated sewage in step 1) to enter the anaerobic-contact oxidation biofilm reactor through gravity flow. Sewage first enters the anaerobic reaction zone of the reactor. Anaerobic biological packing is installed in the anaerobic reaction zone for the attachment and growth of anaerobic microorganisms. The filling rate of anaerobic biological packing in the anaerobic reaction zone is 50%, HRT is 4 hours, and the anaerobic reaction zone The dissolved ...

Embodiment 3

[0056] The method of the present invention is used to treat domestic sewage from a certain urban sewage treatment plant. The raw water quality of the sewage: pH: 7.1, CODcr: 350mg / L, BOD 5 :190mg / L, SS: 70mg / L, NH 4 + -N: 35mg / L, TP: 5mg / L.

[0057] Start the high-efficiency nitrogen and phosphorus removal mode of the internal circulation system:

[0058] 1) The collected township sewage is adjusted and stored in the high-level storage tank and pre-sedimented, forming a 2m water pressure difference with the reactor in the subsequent step 2).

[0059] 2) Control the pre-precipitated sewage in step 1) to enter the anaerobic-contact oxidation biofilm reactor through gravity flow. Sewage first enters the anaerobic reaction zone of the reactor. Anaerobic biological fillers are installed in the anaerobic reaction zone for the attachment and growth of anaerobic microorganisms. The filling rate of anaerobic biological fillers in the anaerobic reaction zone is 60%. The HRT is 5 hours. The ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com