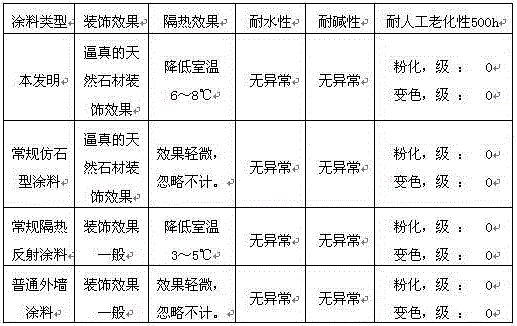

Energy-saving and environment-friendly real stone type composite coating and preparation method and construction method thereof

A coating and real stone technology, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of human health hazards, no heat preservation and energy saving effect, fatality, etc., and achieve excellent water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Finish coating (by weight)

[0065] Pure acrylic emulsion 40 parts, water 48.05 parts, functional material B: 6 parts, additive B: 5.95 parts.

[0066] Functional material B is a mixture of hollow glass microspheres and opaque polymers with a weight ratio of 2.5:1.

[0067] Adjuvants B include dispersants, wetting agents, thickeners, preservatives, defoamers, antifreeze agents and film-forming aids.

[0068] The dispersant is polyacrylic acid ammonium salt, such as the American Dow Chemical, and the dosage is 0.5wt% of the total weight of the paint.

[0069] The wetting agent is WT from BASF, Germany, and the dosage is 0.15wt% of the total weight of the finish coating.

[0070] The thickener is RH-420 from Asahi Denka, and the dosage is 1.5wt% of the total weight of the overcoat coating.

[0071] The preservative is K40 from Schumer, Germany, and the dosage is 0.3wt% of the total weight of the overcoat coating.

[0072] The antifreeze agent is propylene glycol, and ...

Embodiment 2

[0110] Finish coating (by weight)

[0111] Silicone acrylic emulsion 45 parts, water 46.55 parts, functional material B: 3 parts, additive B: 5.55 parts. in:

[0112] Functional material B is a mixture of hollow glass microspheres and opaque polymers with a weight ratio of 1.5:1.

[0113] Adjuvants B include dispersants, wetting agents, thickeners, preservatives, defoamers, antifreeze agents and film-forming aids.

[0114] The dispersant is polyacrylic acid ammonium salt, such as Dow Chemical 2500D, and the dosage is 0.3wt% of the total weight of the finish coating.

[0115] The wetting agent is selected from American Air Chemical Coating Wetting Agent DCO1, and the dosage is 0.10wt% of the total weight of the overcoat coating.

[0116] The thickener is TT-935 from American Dow Chemical, and the dosage is 1.15wt% of the total weight of the finish coating.

[0117] The preservative is A28S from Shumei Company of Germany, and the dosage is 0.25wt% of the total weight of the ...

Embodiment 3

[0155] Finish coating (by weight)

[0156] Pure acrylic emulsion 55 parts, water 30 parts, functional material B: 9 parts, additive B: 6.0 parts.

[0157] Functional material B is a mixture of hollow glass microspheres and opaque polymers with a weight ratio of 1:1.

[0158] Adjuvants B include dispersants, wetting agents, thickeners, preservatives, defoamers, antifreeze agents and film-forming aids.

[0159] The dispersant is polyacrylic acid ammonium salt, such as Dow Chemical 2500D in the United States, and the dosage is 0.7wt% of the total weight of the finish coating.

[0160] The wetting agent is CF-11 from BASF, Germany, and the dosage is 0.15wt% of the total weight of the overcoat coating.

[0161] The thickener is RH-420 from Asahi Denka, and the dosage is 0.45wt% of the total weight of the overcoat coating.

[0162] The preservative is K40 from Germany Shumei Company, and the dosage is 0.15wt% of the total weight of the overcoat coating.

[0163] The defoamer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com