Aluminum chemical polishing solution and polishing method with same

A technology of chemical polishing and polishing liquid, applied in the field of chemical polishing liquid, which can solve the problems of high corrosion rate, too long polishing time, and pitting on the metal surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] Preparation of Cationic Polymers

[0068] Cationic polymers can be prepared by continuous or batch methods using any method known to those skilled in the art, including solution polymerization, emulsion polymerization and suspension polymerization.

[0069] The polymerization of the cationic polymer monomer used in the present invention is initiated by initiator, and the initiator selected can be inorganic peroxygen initiator, such as ammonium persulfate, sodium persulfate, potassium persulfate; azo initiator, Examples include azobisisobutyronitrile and azobisisoheptanonitrile.

[0070] First the initiator decomposes, forming primary free radicals. The obtained primary free radicals further react with monomers to form monomeric free radicals. The decomposition of the initiator is an endothermic reaction with high activation energy. The step of primary free radicals combining with monomers to form monomer free radicals is an exothermic reaction with high activity of ...

Embodiment

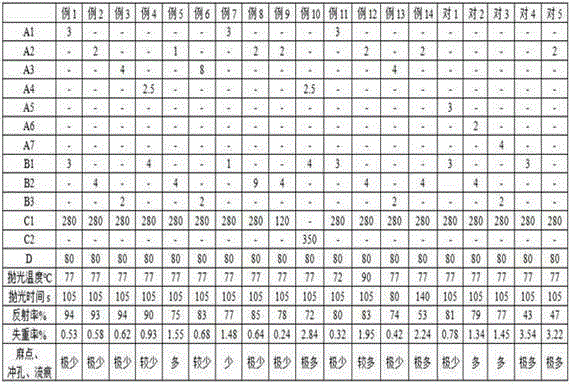

[0113] Embodiment (by weight)

[0114]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com