Composite metal surface treatment agent based on conducting polymer

A metal surface treatment and conductive polymer technology, applied in the field of metal surface treatment, can solve environmental pollution and other problems, and achieve excellent corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

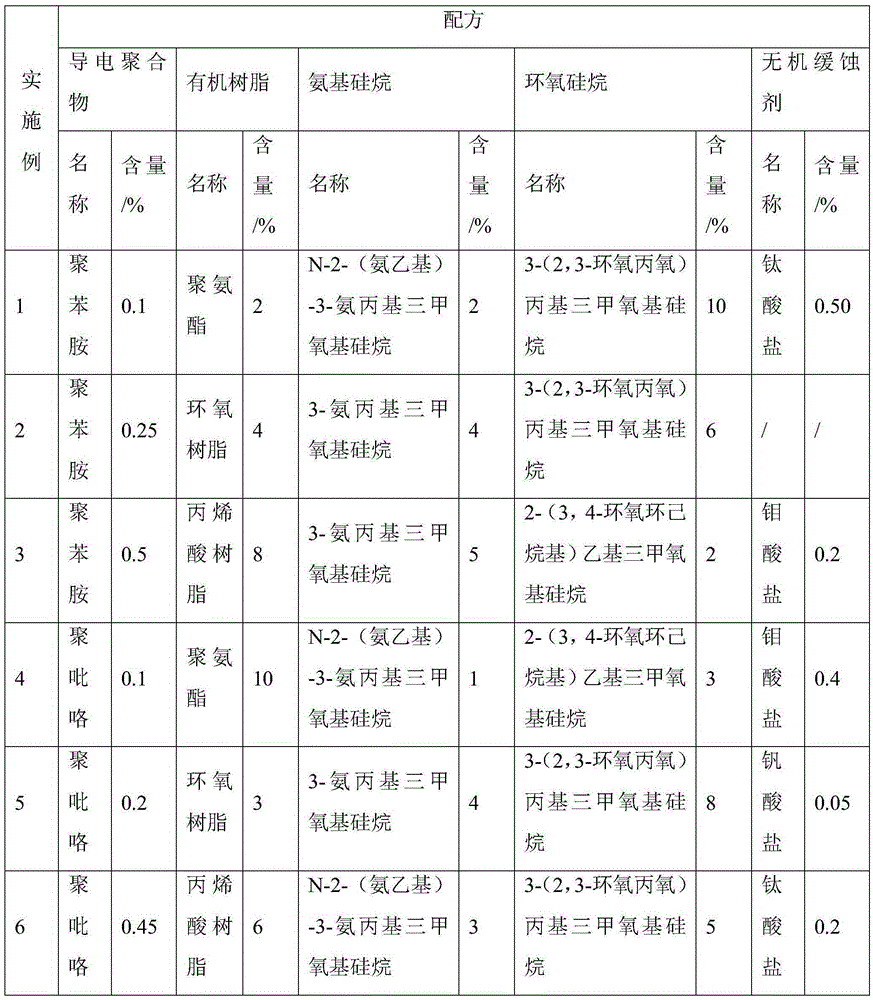

[0017] The present invention will be further described below in conjunction with specific embodiments.

[0018] After the cold-rolled steel plate is polished and derusted, it is degreased with a degreasing solution, rinsed with tap water, rinsed with deionized water, rinsed with industrial alcohol, and dried with hot air before processing.

[0019] The surface of the galvanized sheet is degreased with a degreasing solution, rinsed with tap water, rinsed with deionized water, rinsed with industrial alcohol, and dried with hot air to be pretreated.

[0020] Treatment temperature: room temperature; treatment time: 5-15s; treatment method: dip coating, spray coating, roller coating; curing temperature: 200°C; curing time: 15-60s; film thickness: 0.7-1.5g / m 2 .

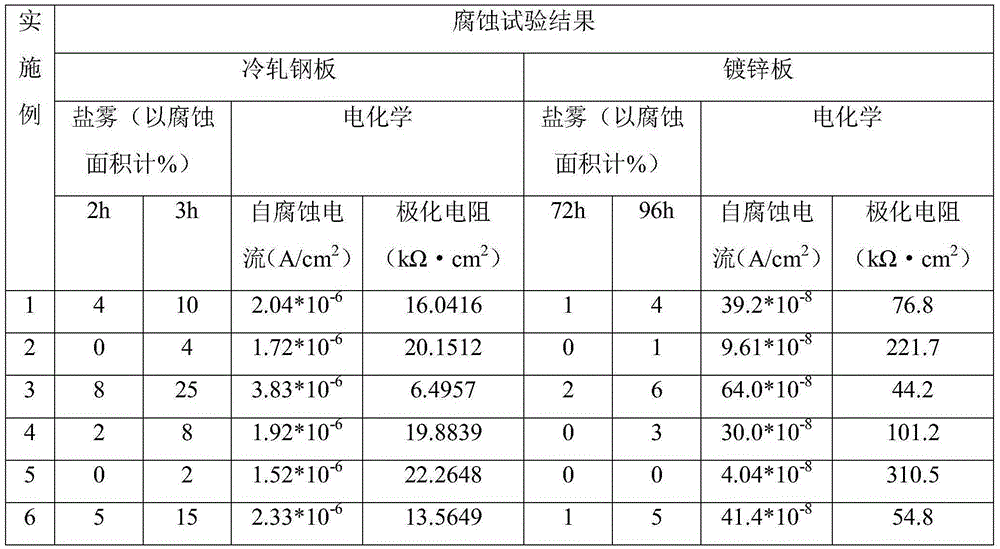

[0021] The evaluation of the corrosion resistance of the film obtained by the present invention is realized by neutral salt spray test and electrochemical auxiliary test. The evaluation results are obtained through the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com