Quantitative analysis method for measuring sulfur in organic thiosulfate

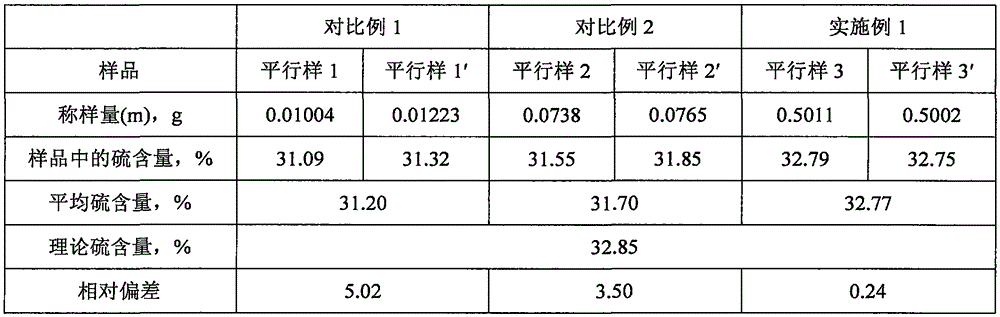

A thiosulfate, quantitative analysis technology, applied in the field of testing and analysis, can solve the problems of complex treatment process, low absolute sulfur content, many interference factors, etc., to achieve good repeatability, less interference factors, and less environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step 1: Drawing of standard curve

[0051] Accurately weigh 19.39g sodium thiosulfate (Na 2 S 2 o 3 ·5H 2O) In a beaker, add water to make it all dissolve, set the volume in a 100mL volumetric flask, and prepare a solution (50g / L); accurately measure the above solution in different volumes (0.0, 2.0, 4.0, 6.0, 8.0, 10.0) Put it in a 50mL volumetric flask, and then dilute it into 6 kinds of standard solutions with different concentrations; scan the standard solution with representative CS lines (257.594nm, 257.961nm and 258.056nm), and adjust the flame height and combustion ratio Finally, select the flame height as: 13mm; air flow: 110L / h; fuel-assist ratio: 0.274, and the absorption line with the maximum absorbance value: 257.594nm. Measure the absorbance of standard solutions with different concentrations at the maximum absorption line 257.594nm, and draw a standard curve.

[0052] Table 1 Drawing of standard curve

[0053] Draw the volume of sulfur stan...

Embodiment 2

[0085] Step 1: Preparation of Sulfur Standard Curve

[0086] Accurately weigh 19.39g sodium thiosulfate (Na 2 S 2 o 3 ·5H 2 O) In a beaker, add water to make it all dissolve, set the volume in a 100mL volumetric flask, and prepare a solution (50g / L); accurately measure the above solution in different volumes (0.0, 2.0, 4.0, 6.0, 8.0, 10.0) Put it in a 50mL volumetric flask, and then prepare standard solutions with different concentrations of 0-10g / L; use representative CS spectral lines (257.594nm, 257.961nm and 258.056nm) to scan the standard solution of the maximum sulfur concentration, and conduct a flame comparison Adjust the height and fuel-assist ratio, finally select the flame height: 13mm; Measure the absorbance of standard solutions with different concentrations at the maximum absorption line 257.594nm, and draw a standard curve.

[0087] Table 3 Drawing of Standard Curve

[0088] Draw the volume of sulfur standard solution (mL)

Sulfur standard curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com