Micron-grade dry mist dust suppression device for belt conveyor

A micron-level, belt conveyor technology, applied in the cleaning device, packaging, transportation and packaging, etc., can solve the problem of aggravating the dust of the belt conveyor, achieve the effect of low operation and maintenance costs, ensure a clean environment, and protect the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

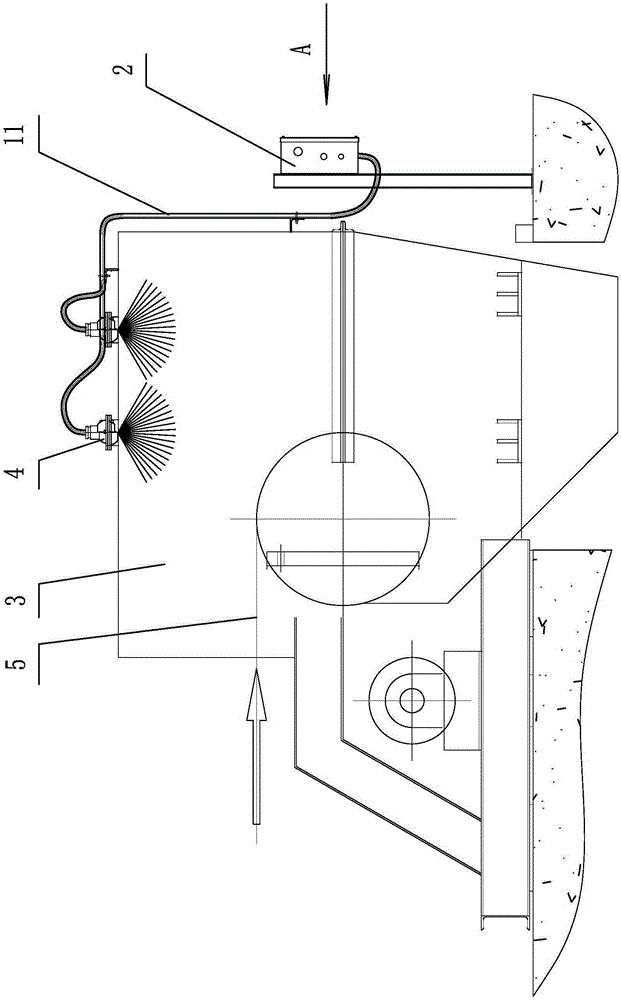

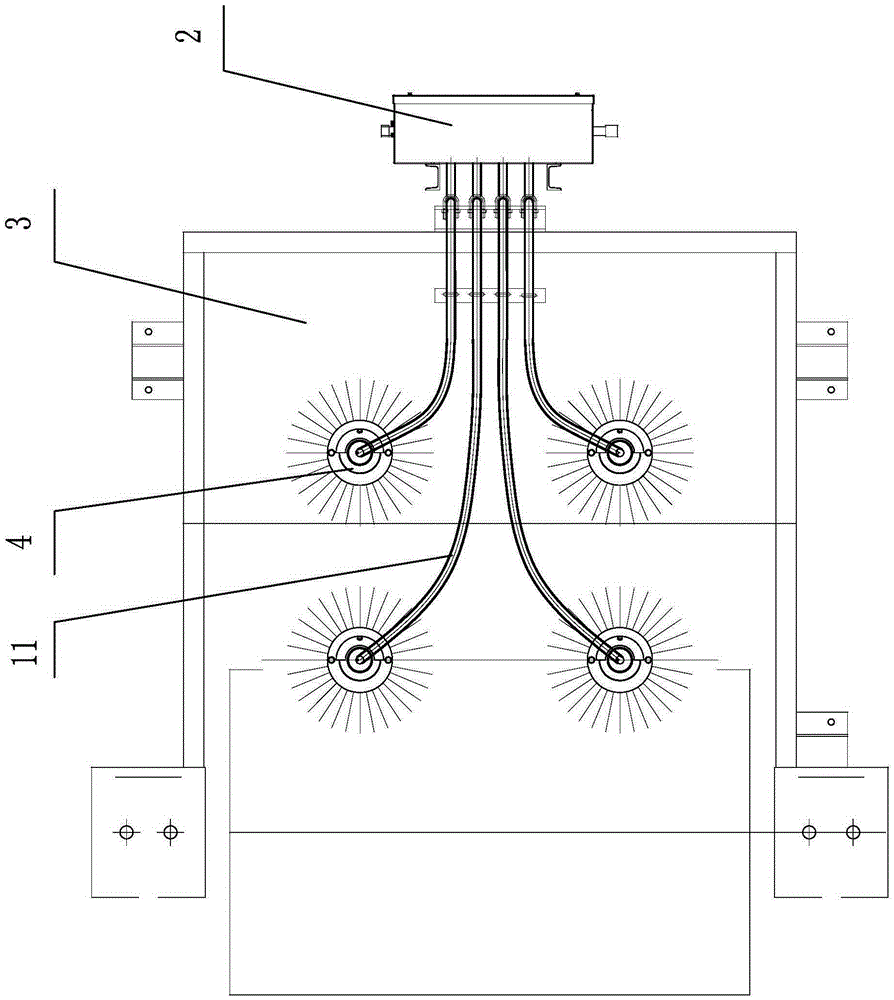

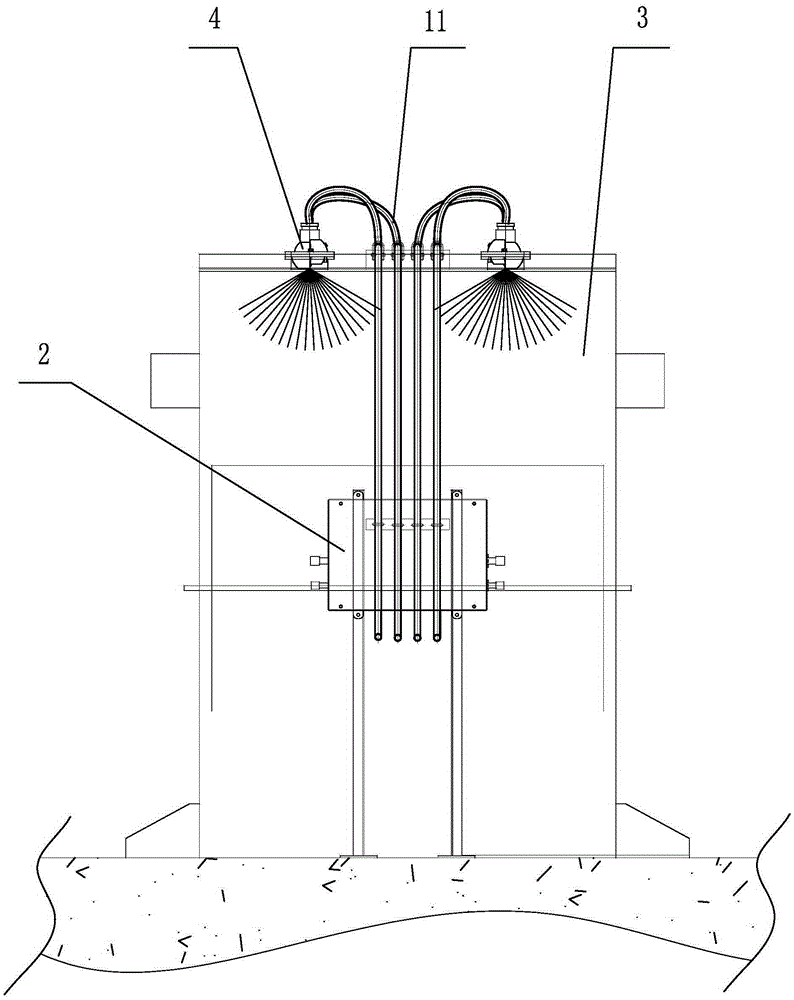

[0022] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0023] Taking the coal yard of the applicant unit as an example, the coal cinders in the coal storage are transferred to the coal users through different belt conveyors. For the coal ash transfer point on the belt conveyor transmission path, the technical solution of the present invention can be used to reduce the dust of the coal ash. Govern.

[0024] The technical solution of the present invention includes a micron-level dry fog machine 1, a water-air distributor 2 and a dry-fog box assembly, the micron-level dry-fog machine 1 is supplied with water by a pump water pipe 7, and the micron-level dry-fog machine 1 is supplied by an air compressor 8 Air supply, the micron-level dry fog machine 1 filters the supplied air and water to set the air pressure and air flow, water pressure and water flow and control the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com