Water removal method for silicon tetrafluoride

A silicon tetrafluoride, water tower technology, applied in the direction of halogenated silicon compounds, halogenated silanes, etc., can solve problems such as difficult removal, and achieve the effect of simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

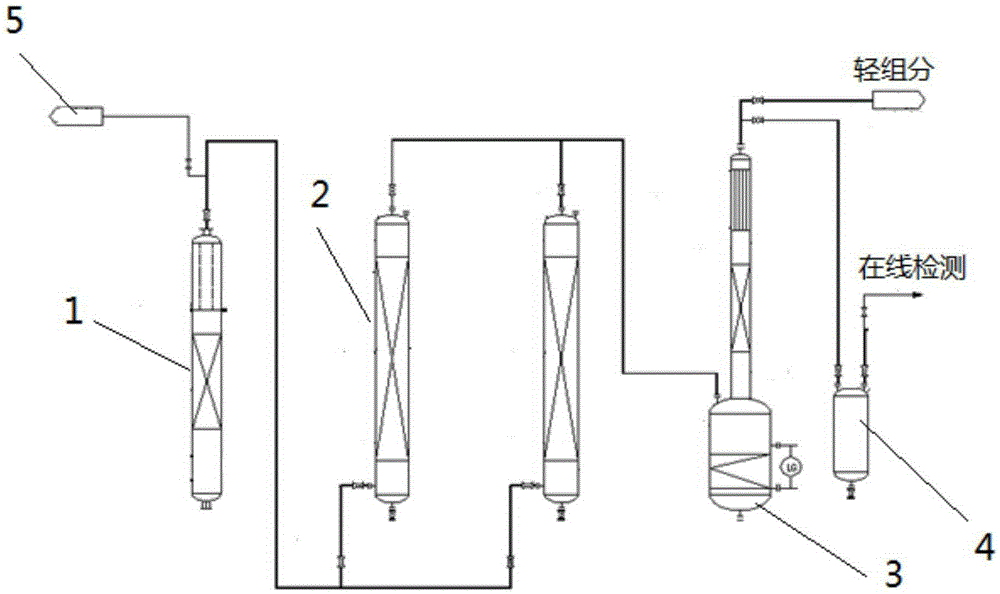

Image

Examples

Embodiment 1

[0048] A method for removing water from silicon tetrafluoride, the specific steps of the method are as follows:

[0049] (1) The operating pressure of the water removal tower is set to be 0.05MPa, and the temperature is -20°C, and silicon tetrafluoride, N 2 Pass carbonyl fluoride into a water removal tower equipped with 4×4 stainless steel θ ring packing, carbonyl fluoride contacts with water in silicon tetrafluoride, a reaction as shown in formula I occurs, and removes water in silicon tetrafluoride , to obtain product 1; product 1 was condensed by a condenser to obtain product 2; after testing, the water content in product 2 was 80ppb.

[0050] COF 2 +H 2 O=CO 2 +2HF I;

[0051] Among them, the condenser uses liquid nitrogen as the condensing medium, and the outlet gas temperature of the condenser is controlled to -30°C by adjusting the flow of liquid nitrogen, and the unreacted carbonyl fluoride is refluxed to the water removal tower through the top condenser for reuse....

Embodiment 2

[0059] A method for removing water from silicon tetrafluoride, the specific steps of the method are as follows:

[0060] (1) The operating pressure of the water removal tower is set to be 1MPa, and the temperature is 30°C, and silicon tetrafluoride, N 2 Pass carbonyl fluoride into a water removal tower equipped with 4×4 stainless steel θ ring packing, carbonyl fluoride contacts with water in silicon tetrafluoride, a reaction as shown in formula I occurs, and removes water in silicon tetrafluoride , to obtain product 1; product 1 was condensed by a condenser to obtain product 2; after testing, the water content in product 2 was 20ppb.

[0061] COF 2 +H 2 O=CO 2 +2HF I;

[0062] Among them, the condenser uses liquid nitrogen as the condensing medium, and the outlet gas temperature of the condenser is controlled to -30°C by adjusting the flow of liquid nitrogen, and the unreacted carbonyl fluoride is refluxed to the water removal tower through the top condenser for reuse.

...

Embodiment 3

[0070] A method for removing water from silicon tetrafluoride, the specific steps of the method are as follows:

[0071] (1) The operating pressure of the water removal tower is set to be 0.5MPa, and the temperature is 20°C, and silicon tetrafluoride, O 2 Pass carbonyl fluoride into a water removal tower equipped with 4×4 stainless steel θ ring packing, carbonyl fluoride contacts with water in silicon tetrafluoride, a reaction as shown in formula I occurs, and removes water in silicon tetrafluoride , to obtain product 1; product 1 was condensed by a condenser to obtain product 2; after testing, the water content in product 2 was 50ppb.

[0072] COF 2 +H 2 O=CO 2 +2HF I;

[0073] Among them, the condenser uses liquid nitrogen as the condensing medium, and the outlet gas temperature of the condenser is controlled to -40°C by adjusting the flow rate of liquid nitrogen, and the unreacted carbonyl fluoride is refluxed to the water removal tower through the top condenser for reu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com