Method for efficiently preparing thermal-stability-type slowly digestible starch by combining chemical method and enzymic method

A slow-digesting starch, chemical combination technology, applied in the field of high-efficiency chemical combined with enzymatic modification to prepare heat-stable slow-digesting starch, can solve the problems of reducing the sensitivity of digestive enzymes, poor thermal stability of SDS, low SDS content, etc. Simple, thermally stable, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

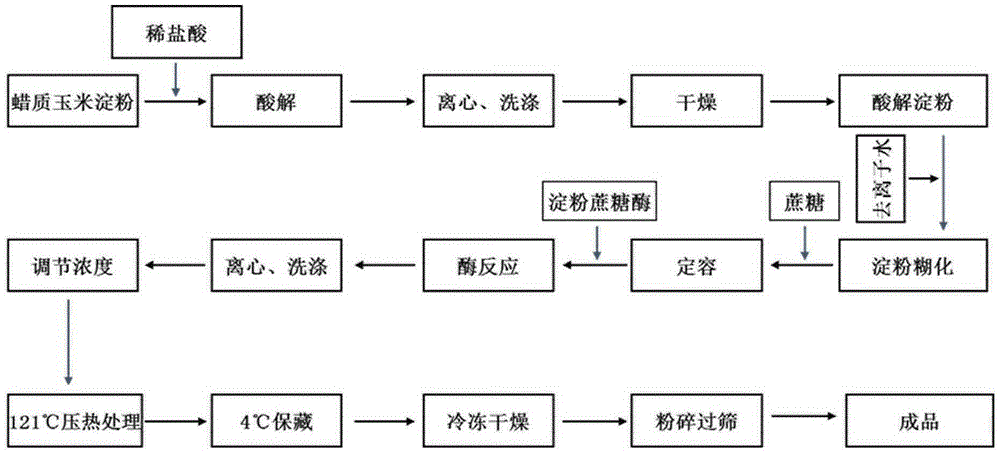

Method used

Image

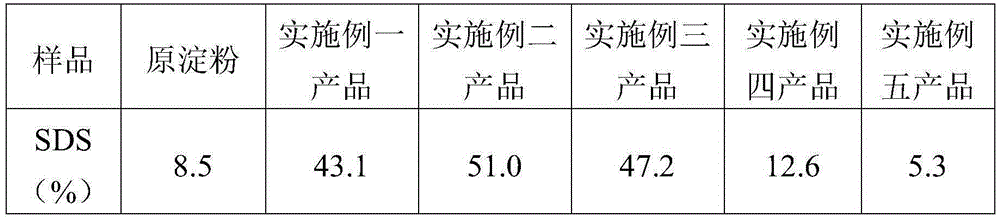

Examples

Embodiment 1

[0025] 1. Take 100g of waxy cornstarch, add 233.3g of 0.14mol / L dilute hydrochloric acid, and acidolysis it in a water bath at 40°C for 6 hours;

[0026] 2. After the acid hydrolysis treatment, wash with 3 to 4 times the volume of deionized water and centrifuge, discard the supernatant, repeat the washing 3 times, dry the precipitate in a 45°C oven for 24 hours, crush it and pass it through a 200-mesh sieve. Obtain the acid-thinned starch product;

[0027] 3. Weigh 60g of acid-thinned starch, add 800mL of deionized water, heat the solution to 100°C and boil for 15 minutes to completely gelatinize the starch. After the solution is cooled to 30°C, add 120g of sucrose, and stir the solution until the sucrose is completely dissolved. Add deionized water and make up to 1L;

[0028] 4. Add amylosucrase to make the enzyme activity 1000U / L, react at a constant temperature for 8 hours at a stirring speed of 200r / min, and the reaction temperature is 30°C;

[0029] 5. After the reactio...

Embodiment 2

[0032] 1. Take 150g of waxy cornstarch, add 225g of 0.14mol / L dilute hydrochloric acid, and acidolyze it in a water bath at 45°C for 8 hours;

[0033] 2. After the acid hydrolysis treatment, wash with 3 to 4 times the volume of deionized water and centrifuge, discard the supernatant, repeat the washing 3 times, dry the precipitate in an oven at 50°C for 36 hours, crush it and pass it through a 200-mesh sieve. Obtain the acid-thinned starch product;

[0034] 3. Weigh 80g of acid-thinned starch, add 800mL of deionized water, heat the solution to 100°C and boil for 15 minutes to completely gelatinize the starch. After the solution is cooled to 35°C, add 160g of sucrose, and stir the solution until the sucrose is completely dissolved. Add deionized water and make up to 1L;

[0035] 4. Add amylosucrase to make the enzyme activity 1500U / L, react at a constant temperature for 10 hours at a stirring speed of 200r / min, and the reaction temperature is 35°C;

[0036] 5. After the react...

Embodiment 3

[0039] 1. Take 200g of waxy corn starch, add 200g of 0.14mol / L dilute hydrochloric acid, and then acidolysis it in a water bath at 50°C for 10 hours;

[0040] 2. After the acid hydrolysis treatment, wash with 3 to 4 times the volume of deionized water and centrifuge, discard the supernatant, repeat the washing 3 times, dry the precipitate in a 55°C oven for 48 hours, crush it and pass it through a 200-mesh sieve. Obtain the acid-thinned starch product;

[0041] 3. Weigh 100g of acid-thinned starch, add 800mL of deionized water, heat the solution to 100°C and boil for 15 minutes to completely gelatinize the starch. After the solution is cooled to 40°C, add 200g of sucrose, and stir the solution until the sucrose is completely dissolved. Add deionized water and make up to 1L;

[0042] 4. Add amylosucrase to make the enzyme activity 2000U / L, react at a constant temperature for 12 hours at a stirring speed of 200r / min, and the reaction temperature is 40°C;

[0043]5. After the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com