Anticorrosive paint added with graphene composite material and preparation method thereof

A technology of composite materials and anti-corrosion coatings, applied in anti-corrosion coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problems of insignificant improvement of anti-corrosion performance, limited application range, single anti-corrosion effect, etc. Focus on the effect of not easy to crack, wide range of use, and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

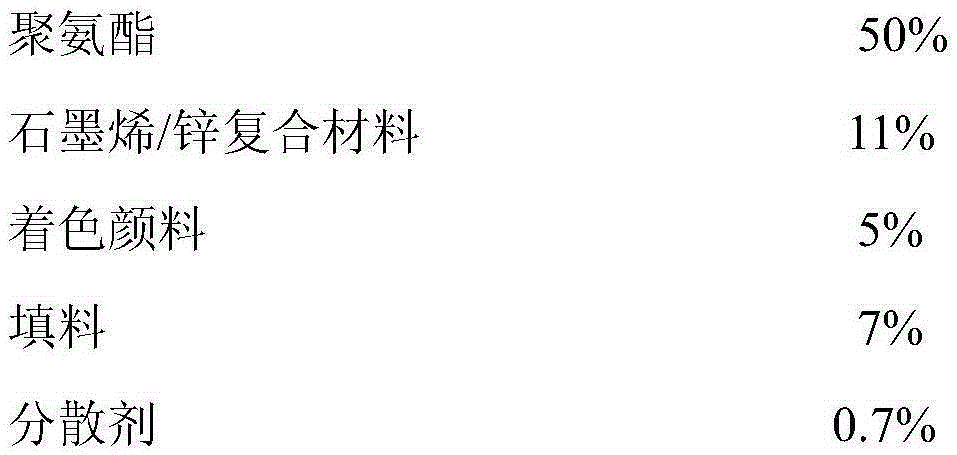

[0019] Proportioning each component according to the following mass percentages:

[0020]

[0021] (1) Put 300g of graphene powder into a fluidized bed reactor, feed nitrogen into the reactor as a protective gas to increase the material layer to 1 / 4 of the bed, preheat to 500°C, and keep warm for 20min;

[0022] (2) Increase the reactor temperature to 650°C, add zinc powder to the reactor to continuously vaporize it at high temperature, and become zinc vapor. The amount of zinc powder added is 3 times that of graphene powder, and the amount of protective gas is adjusted. The flow rate increases the material layer to 1 / 2 of the bed layer;

[0023] (3) After the zinc powder is completely vaporized, continue the reaction for 1 hour, during which the temperature is lowered to 150°C at a constant speed, and the heating is stopped after 30 minutes of heat preservation, and the nitrogen gas is continued until the material is cooled. The material obtained after the reaction is cru...

Embodiment 2

[0026] Proportioning each component according to the following mass percentages:

[0027]

[0028]

[0029] (1) Put 300g of graphene powder into a fluidized bed reactor, feed nitrogen into the reactor as a protective gas to increase the material layer to 1 / 3 of the bed, preheat to 500°C, and keep warm for 30min;

[0030] (2) Increase the reactor temperature to 650°C, add zinc powder into the reactor to continuously vaporize it at high temperature, and become zinc vapor. The amount of zinc powder added is 3.5 times that of graphene powder, and the amount of protective gas is adjusted. The flow rate increases the material layer to 1 / 2 of the bed layer;

[0031] (3) After the zinc powder is completely vaporized, continue the reaction for 1 hour, during which the temperature is lowered to 160°C at a constant speed, and the heating is stopped after 20 minutes of heat preservation, and the nitrogen gas is continued until the material is cooled. The material obtained after the...

Embodiment 3

[0034] Proportioning each component according to the following mass percentages:

[0035]

[0036]

[0037] (1) 300g of graphene powder is loaded into a fluidized bed reactor, and nitrogen gas is introduced into the reactor as a protective gas to increase the material layer to 1 / 3 of the bed layer, preheat to 550° C., and keep warm for 20 minutes;

[0038] (2) Increase the reactor temperature to 700°C, add zinc powder to the reactor to continuously vaporize it at high temperature, and become zinc vapor. The amount of zinc powder added is 4 times that of graphene powder, and the amount of protective gas is adjusted. The flow rate increases the material layer to 1 / 2 of the bed layer;

[0039] (3) After the zinc powder is completely vaporized, the reaction is continued for 1 hour, during which the temperature is lowered to 160°C at a constant speed, and the heating is stopped after 30 minutes of heat preservation, and the nitrogen gas is continued until the material is cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com