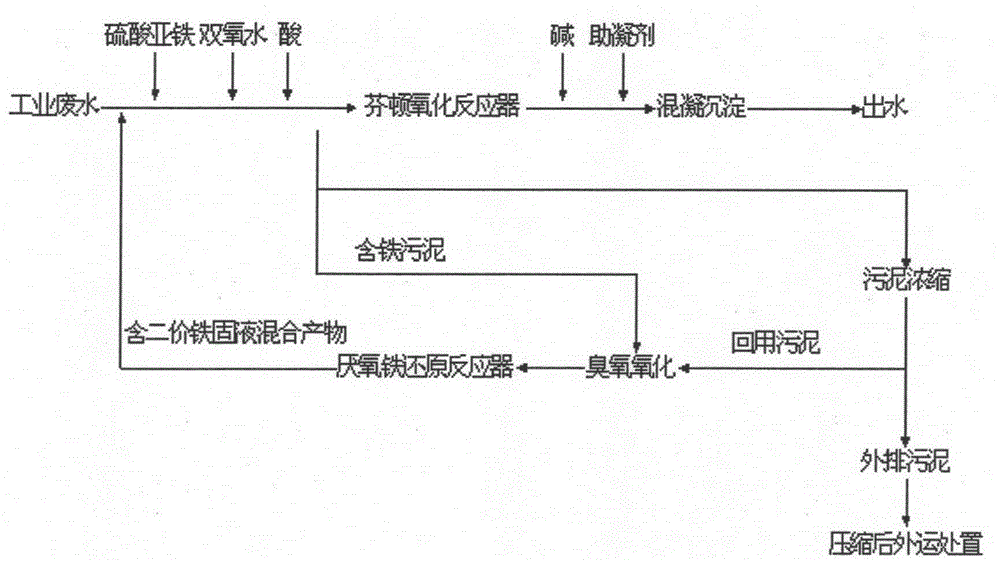

Ozone-anaerobic iron reduction combined Fenton oxidation technology for sludge reduction

A Fenton oxidation and sludge reduction technology, which is applied in the oxidation treatment of sludge, sludge treatment, biological sludge treatment, etc., can solve the problems of large iron sludge discharge, high disposal cost, and large salt consumption. Achieve the effect of reducing emissions, saving project operating costs, and reducing process operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A printing and dyeing enterprise in Zhejiang, the wastewater discharged includes printing, dyeing, scouring, and desizing wastewater. The mixed wastewater COD=1000-2000mg / L, after treatment, it needs to meet the discharge standard of COD≤200mg / L and discharge it into the sewage of the industrial park Pipe Network. Adopting the Fenton oxidation treatment process of ozone-anaerobic iron reduction combined with sludge reduction proposed by the present invention, the specific method and steps are: (1) the biochemical effluent of printing and dyeing wastewater enters Fenton oxidation-hydrolytic acidification-aerobic treatment, and The final effluent COD≤200mg / L; (2) add part of the iron-containing sludge produced by the Fenton oxidation unit to the ozone reaction tank, and react for 20 minutes; (3) then enter the anaerobic iron reduction reactor, and react for 24 hours. More than 90% Fe in the sludge 3+ converted to Fe 2+ (4) finally the Fe in the anaerobic iron reduction ...

Embodiment 2

[0019] A fluorine chemical company in Jiangsu province discharged wastewater with COD=10000-20000 mg / L, and there were many organic suspended solids in the wastewater, which were difficult to remove by traditional flocculation and sedimentation, which resulted in fouling and reduced effectiveness of subsequent evaporation devices. After the wastewater is treated with Fenton oxygen, the water quality is relatively clear, which can meet the subsequent evaporation requirements; however, a large amount of iron-containing sludge and residual sludge are produced during the Fenton oxidation process, and the disposal is difficult and expensive. Adopt the Fenton oxidation process that ozone-anaerobic iron reduction combined with sludge reduction that the present invention proposes, concrete method and step are: (1) waste water enters Fenton oxidation process treatment; (2) Fenton oxidation unit produces Part of the iron-containing sludge is added to the ozone oxidation reactor and react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com