Novel digested-effluent organic liquid fertilizer and preparation method therefor

A technology of organic liquid fertilizer and biogas slurry, applied in fertilization device, fertilizer mixture, application, etc., can solve the problems of root damage, little effect, high cost, etc., achieve strong adsorption and dissolution capacity, long survival time, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

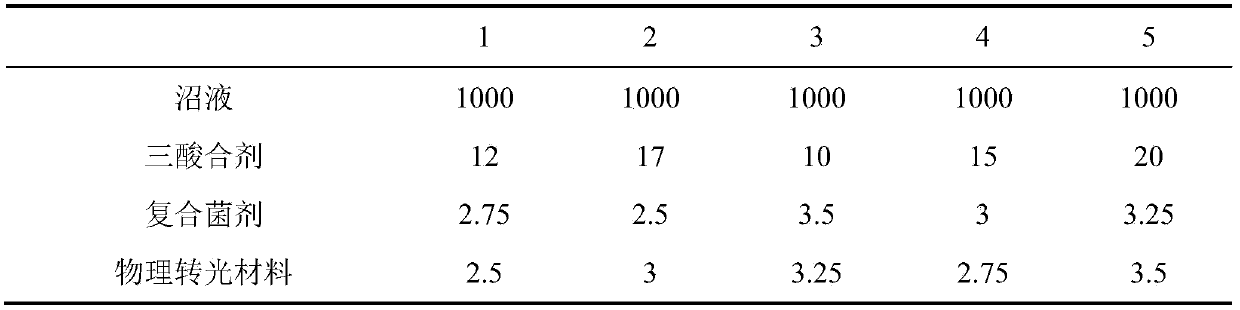

[0033] The new biogas slurry organic liquid fertilizer of this embodiment is prepared according to the following steps: after the biogas slurry is pre-filtered with a laminated filter, large particles such as sand and stones are removed, and ozone is used for sterilization; the biogas slurry sterilized by ozone is sterilized Fine filtration (filter accuracy: 5 μm) and ultraviolet sterilization; add the above-mentioned three-acid mixture, compound bacterial agent, and physical light-transforming material into the biogas slurry to obtain a new type of biogas slurry organic liquid fertilizer. Wherein the amount of each raw material is shown in Table 1.

[0034] The biogas slurry mentioned above is the biogas slurry after coarse filtration, fine filtration, and sterilization; the three-acid mixture is amino acid, humic acid, and biochemical fulvic acid with a mass ratio of 1:1:1; biochemical fulvic acid is obtained from Extracted from plant waste after microbial fermentation, the ...

Embodiment 2

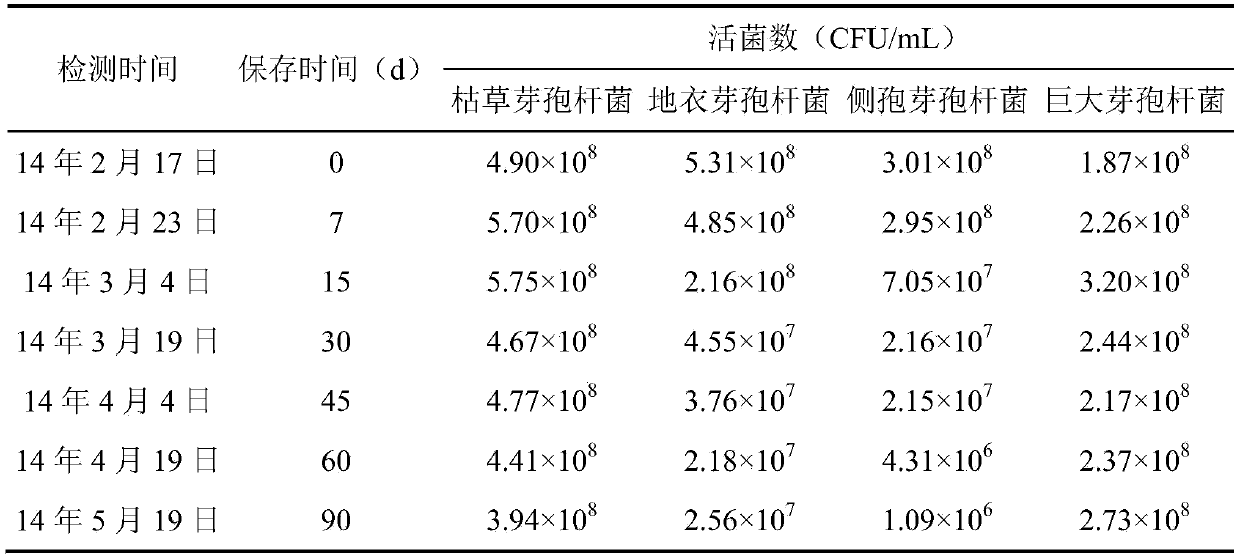

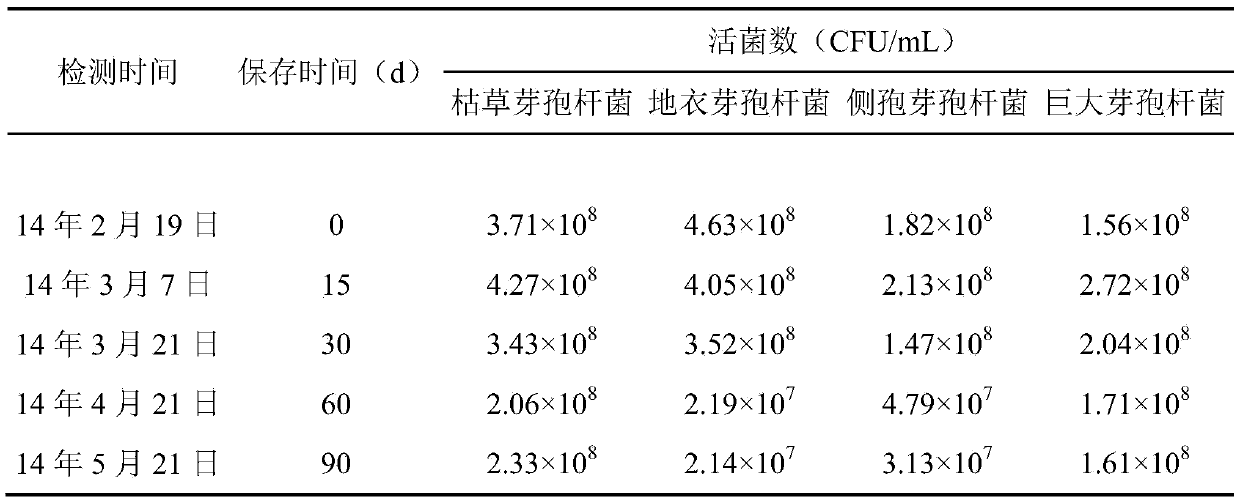

[0039] The results of the survival experiment of the bacteria in the composite microbial agent in the present invention in the biogas slurry are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com