A kind of method for preparing formate by catalytic hydrogenation of carbon dioxide

A carbon dioxide, catalytic hydrogenation technology, applied in the preparation of carboxylate, organic chemistry, etc., can solve the problems of limited application and high temperature, and achieve the effects of simple operation, short preparation route and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 20mL reactor, add sodium hydroxide (0.2mmol), nanoporous palladium (prepared from Pd-Al alloy, 0.01mmol) and deionized water (2mL). Recharge with CO 2 to 1MPa. Put the reaction kettle in an oil bath at 60°C, react for 25 hours, take out the reaction kettle, put it in water, cool to ambient temperature, open the reaction kettle, take out the reaction solution and remove the solvent with a rotary evaporator to obtain sodium formate.

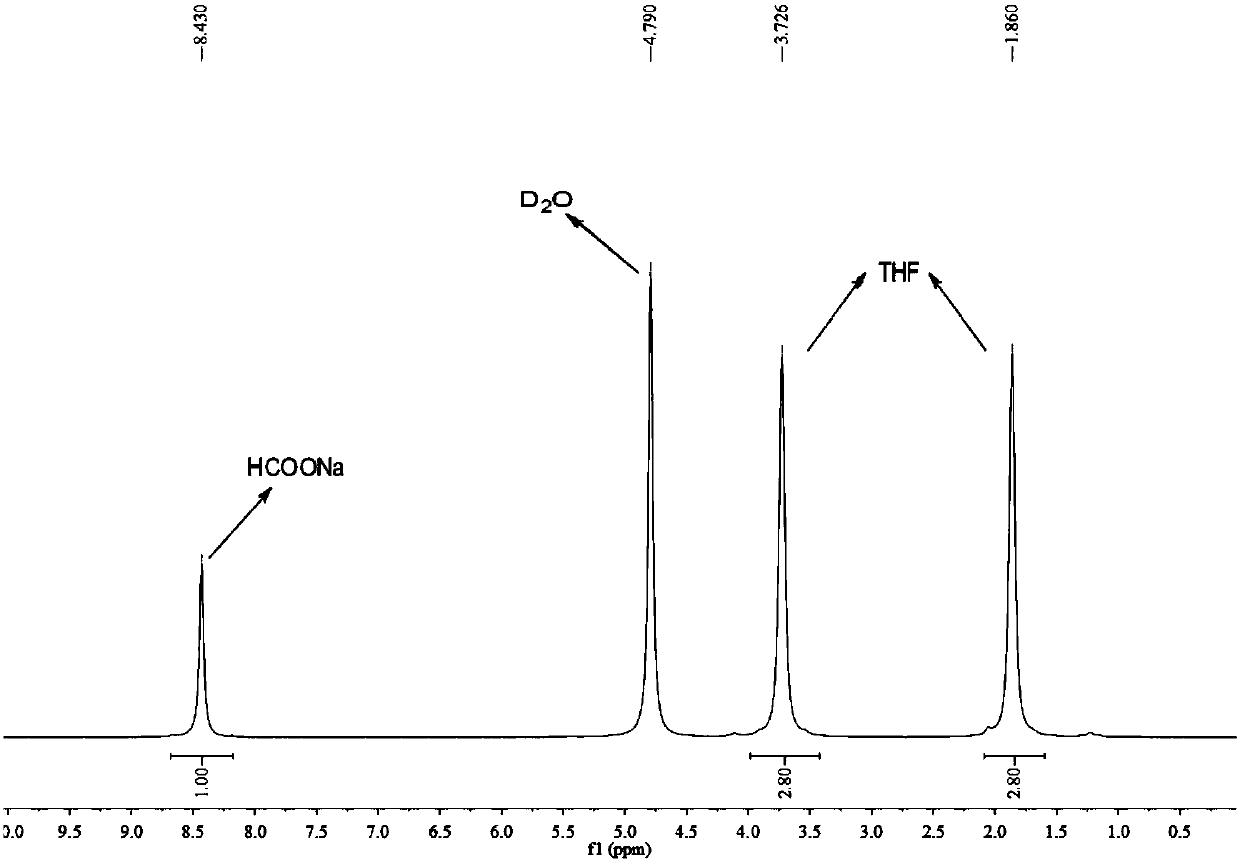

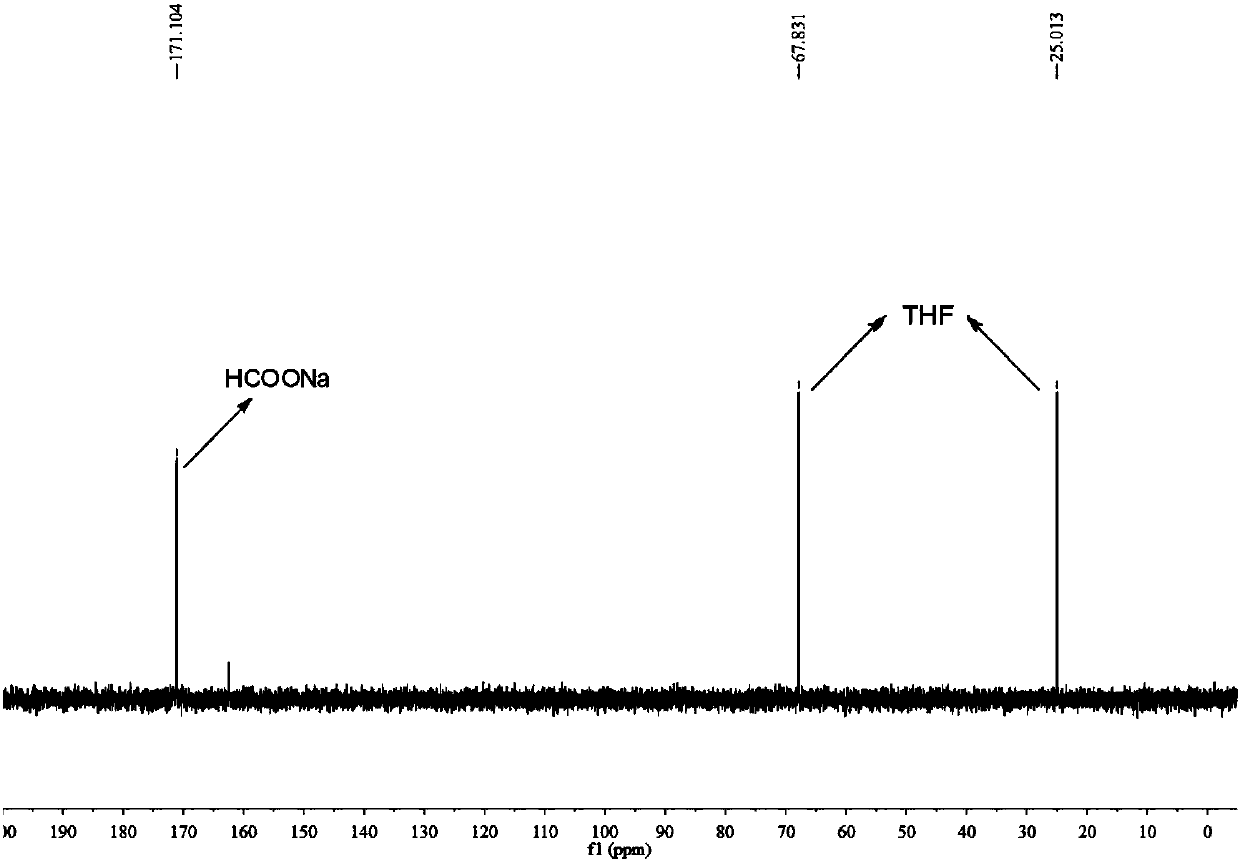

[0022] Sodium formate (HCO 2 Na):

[0023] white solid; 1 H-NMR (400MHz,D 2 O)δ8.42(s,1H); 13 C-NMR (100MHz,D 2 O) δ171.1.

Embodiment 2

[0025] In a 20mL reactor, add potassium hydroxide (1mmol), nanoporous palladium (prepared from Pd-Al alloy, 0.05mmol), deionized water and methanol (10:1, 2mL), replace hydrogen three times, and then fill Hydrogen to 1MPa, then filled with CO 2 to 2MPa. Put the reaction kettle in an oil bath at 100°C, react for 24 hours, take out the reaction kettle, put it in water, cool to ambient temperature, open the reaction kettle, take out the reaction liquid and remove the solvent with a rotary evaporator to obtain potassium formate.

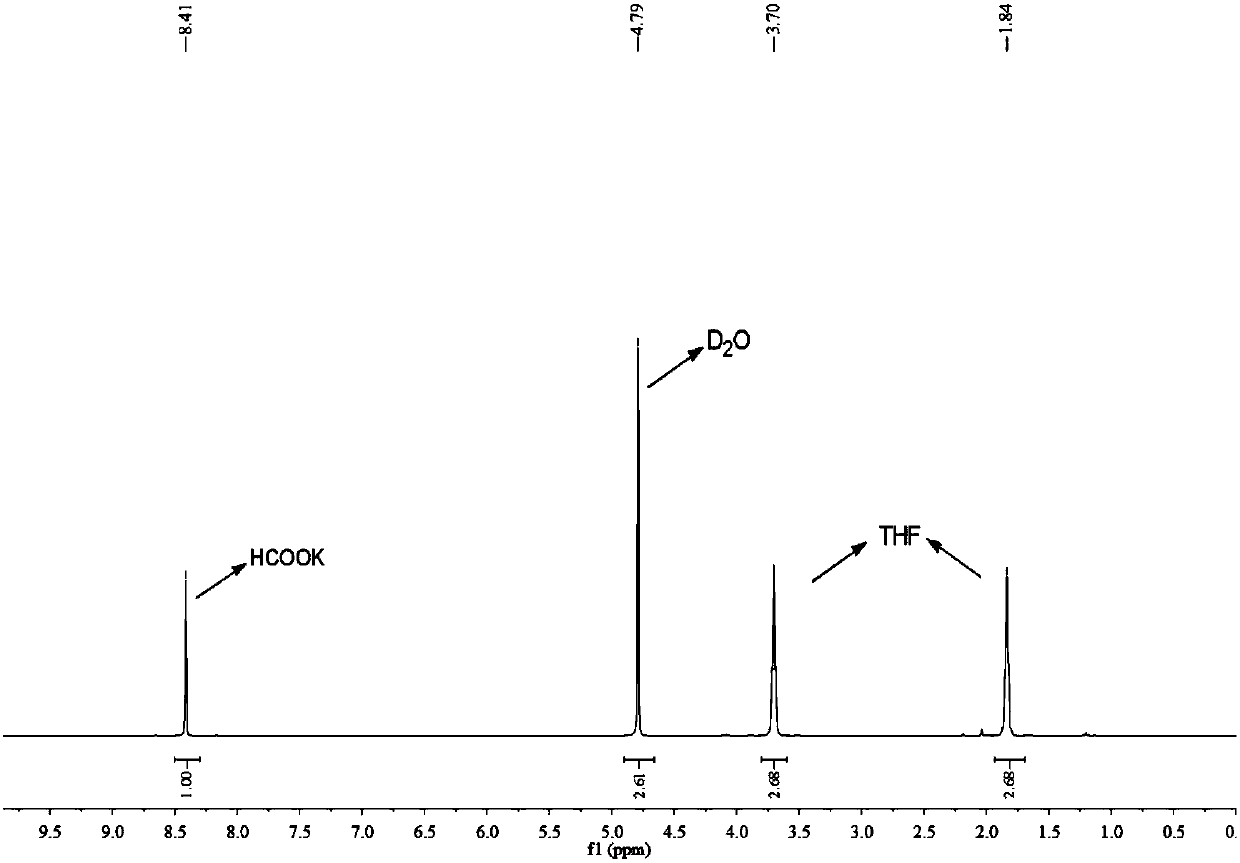

[0026] Potassium formate (HCO 2 K):

[0027] white solid; 1 H-NMR (400MHz,D 2 O)δ8.41(s,1H); 13 C-NMR (100MHz,D 2 O) δ171.3.

Embodiment 3

[0029] In a 20mL reactor, add sodium bicarbonate (2mmol), nanoporous palladium (prepared from Pd-Al alloy, 0.1mmol), a mixed solvent of deionized water and ethanol (10:1, 2mL), and replace with hydrogen for 3 times , fill with hydrogen to 0.25MPa first, then fill with CO 2 to 0.5MPa. Put the reaction kettle in an oil bath at 40°C, react for 22 hours, take out the reaction kettle, put it in water, cool to ambient temperature, open the reaction kettle, take out the reaction solution and remove the solvent with a rotary evaporator to obtain sodium formate.

[0030] Sodium formate (HCO 2 Na): white solid; 1 H-NMR (400MHz,D 2 O)δ8.42(s,1H); 13 C-NMR (100MHz,D 2 O) δ171.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com