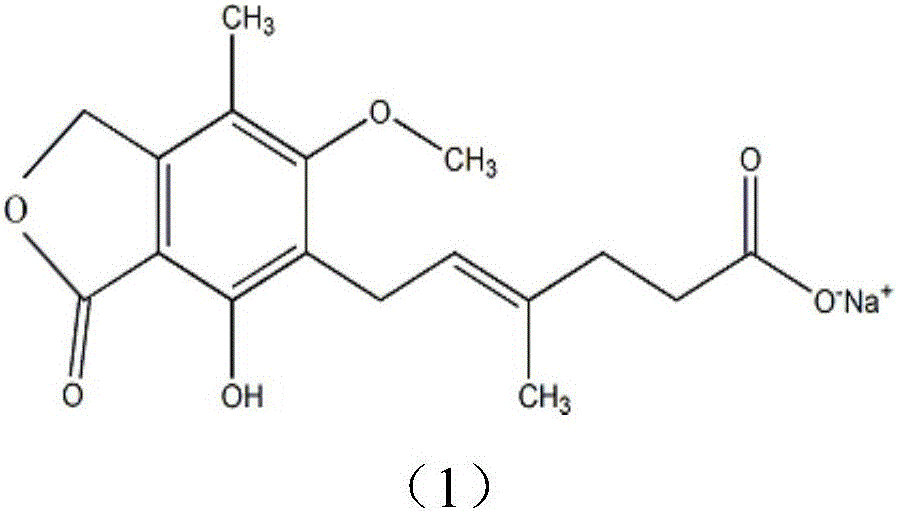

Method for preparing mycophenolate sodium from mycophenolic acid strains

A technology for mycophenolic acid bacteria and mycophenolic acid sodium, which is applied in the field of preparing mycophenolic acid sodium from mycophenolic acid strains, can solve the problem of "mycophenolic acid sodium, long synthesis route and environmental pollution that cannot be directly prepared to obtain the final product". and other problems, to achieve the effect of reducing the harm to the environment and human body, the preparation route is short, and the operation procedure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for preparing mycophenolate sodium from mycophenolic acid bacterial strains comprises the following steps.

[0025] Step (1): Take the spore suspension of mycophenolic acid-producing bacteria, inoculate it on the seed medium, and cultivate it at 28° C. for 4 days. The components in the seed medium are (unit: g / L): 5 soybean cake powder, 40 lactose, 20 corn steep liquor powder, 1 ammonium nitrate, 1 potassium dihydrogen phosphate, 1 calcium carbonate, and the balance is water.

[0026] In step (2), the seed medium is inoculated in a fermenter, and a fermentation medium is added, and cultured at 26° C. for 10 days. Components in the fermentation medium (unit: g / L): 15 soybean cake powder, 5 corn starch, 45 glucose, 70 fructose, 45 corn steep liquor powder, 1 calcium carbonate, 2 methionine, 0.5 potassium dihydrogen phosphate, and The amount is water. After the fermentation is completed, the tank is put into the tank to extract the fermentation liquid.

[002...

Embodiment 2

[0032] The method for preparing mycophenolate sodium from mycophenolic acid bacterial strains comprises the following steps.

[0033] Step (1), take the spore suspension of mycophenolic acid-producing bacteria, inoculate it on the culture medium, and cultivate it for 3 days at 26°C; each component in the seed culture medium is (unit: g / L): soybean meal powder 10. Lactose 50, corn steep liquor dry powder 25, ammonium nitrate 2, potassium dihydrogen phosphate 2, calcium carbonate 2, and the balance is water.

[0034] In step (2), the seed medium is inoculated in a fermenter, and a fermentation medium is added, and cultured at 26° C. for 9 days. The components in the fermentation medium are (unit: g / L): soybean cake powder 20, corn starch 10, glucose 50, fructose 80, corn steep liquor powder 50, calcium carbonate 1, methionine 3, potassium dihydrogen phosphate 0.5, The balance is water. After the fermentation is completed, the tank is put into the tank to extract the fermentati...

Embodiment 3

[0040] The method for preparing mycophenolate sodium from mycophenolic acid bacterial strains comprises the following steps.

[0041] Step (1), take the spore suspension of mycophenolic acid-producing bacteria, inoculate it on the culture medium, and cultivate it for 4 days at 28°C; each component in the seed culture medium is (unit: g / L) soybean cake powder 15 , lactose 60, corn steep liquor dry powder 40, ammonium nitrate 3, potassium dihydrogen phosphate 3, calcium carbonate 3, and the balance is water.

[0042]In step (2), the seed medium is inoculated in a fermenter, and a fermentation medium is added, and cultured at 28° C. for 11 days. The components in the fermentation medium are (unit: g / L): soybean cake powder 25, corn starch 15, glucose 65, fructose 90, corn steep liquor powder 55, calcium carbonate 3, methionine 4, potassium dihydrogen phosphate 1.5, The balance is water. After the fermentation is completed, the tank is put into the tank to extract the fermentati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com