A kind of preparation method and application of hexafluoropropane-based PMO thin film

A technology of hexafluoropropane and hexafluoropropane is applied in the field of preparation of ordered mesoporous organosilicon thin films, which can solve the problems of low dielectric constant of PMO thin films, enhanced noise interference, signal transmission delay, etc., so as to reduce the dielectric Constant, solve the signal transmission delay, reduce the effect of modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, when preparing the hexafluoropropane-based PMO film, the required raw materials are: 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (BAHP), Thichner reagent, purity 95% , specification 25g; 3-(triethoxysilyl)propyl isocyanate (TPI), Aladdin reagent, purity 95%, specification 100g; acetone, Sinopharm reagent, dried by molecular sieves; ethanol, Sinopharm reagent, dried by molecular sieves; Hydrochloric acid, Sinopharm Reagent; Tetrapolyethylene glycol monolauryl ether Sigma reagent, average molecular weight 362, specification 100mL.

[0051] The preparation method of the hexafluoropropane-based PMO thin film of the present embodiment comprises the steps:

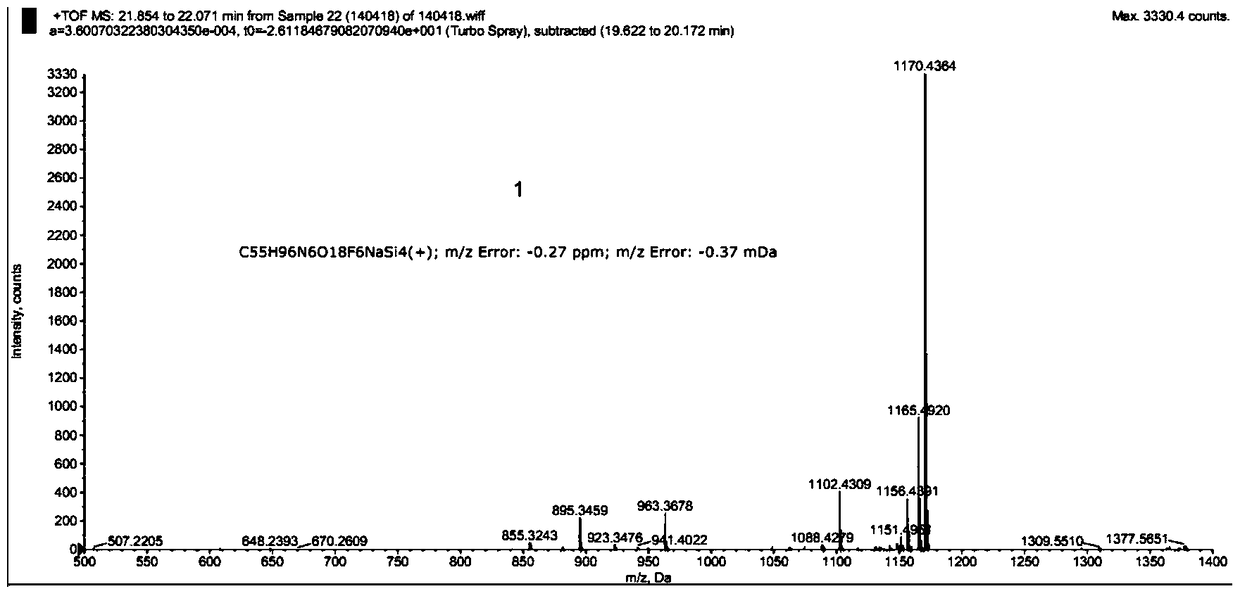

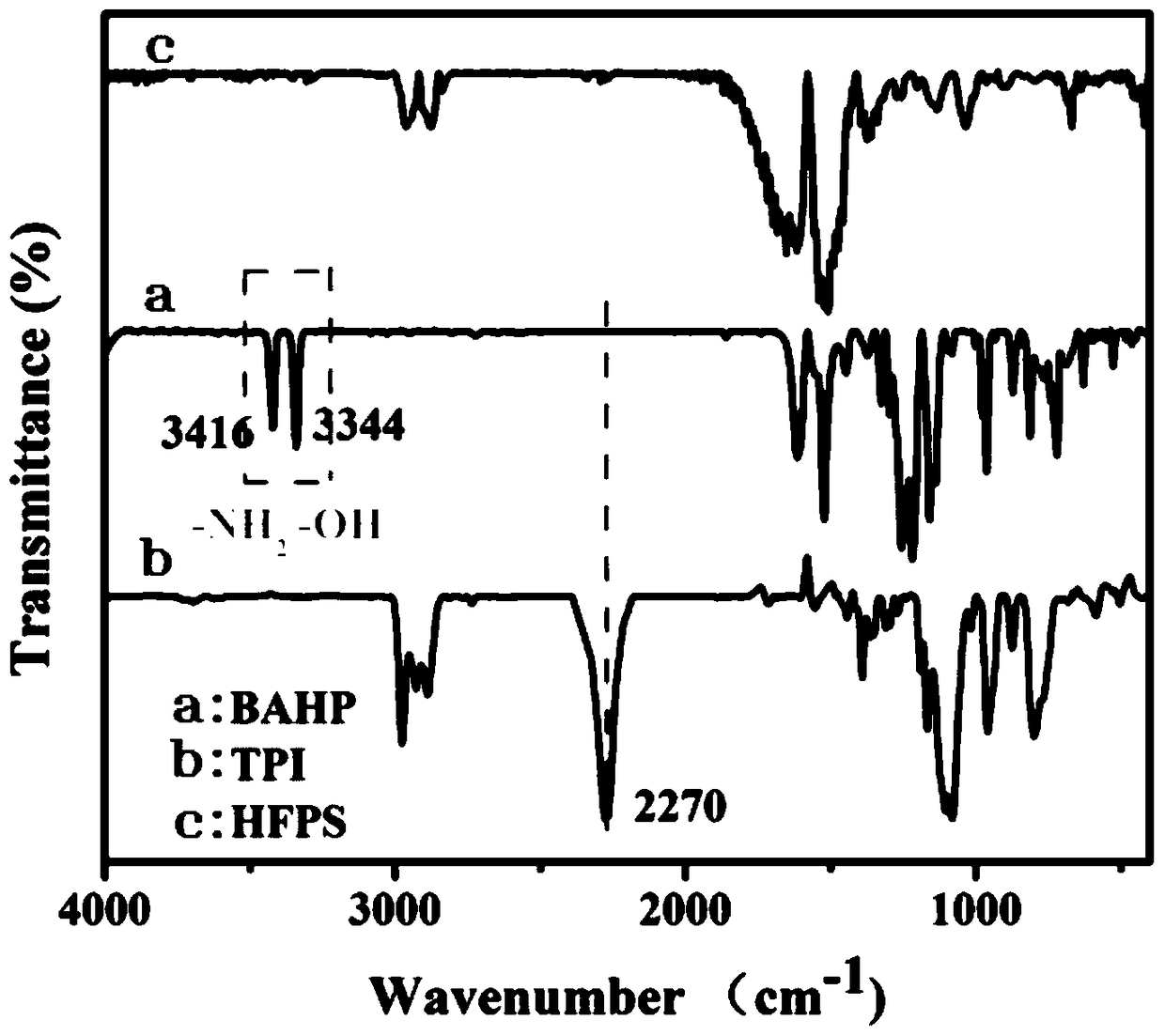

[0052] (1) Preparation of hexafluoropropane-based precursor molecular solution; respectively configure 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (BAHP) acetone solution and isocyanate-3-(triethyl Acetone solution of oxysilyl)propyl ester (TPI). Wherein the concentration of the aceton...

Embodiment 2

[0070] The difference between the preparation method of the PMO film in this example and Example 1 is that the quality of the template is 25% of the molecular weight of the precursor; meanwhile, by adjusting the amount of ethanol and dilute hydrochloric acid, the precursor molecules in the coating solution The concentration is the same as in Example 1.

[0071] Other steps of the preparation method of the PMO thin film in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0073] The difference between the preparation method of the PMO film in this example and Example 1 is that the quality of the template agent is 50% of the molecular weight of the precursor; at the same time, by adjusting the amount of ethanol and dilute hydrochloric acid, in the coating solution, the precursor molecules The concentration is the same as in Example 1.

[0074] Other steps of the preparation method of the PMO thin film in this embodiment are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com