Preparation method of super-tough polystyrene acrylonitrile copolymer/thermoplastic elastomer/rigid particle ternary blend

A technology of polystyrene acrylonitrile copolymer and polystyrene acrylonitrile, which is applied in the field of continuous edge-limiting pressure-induced flow processing and molding, can solve the problems of low processing efficiency and poor mechanical properties of SAN, and achieve high production efficiency, Effect of improved impact strength and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

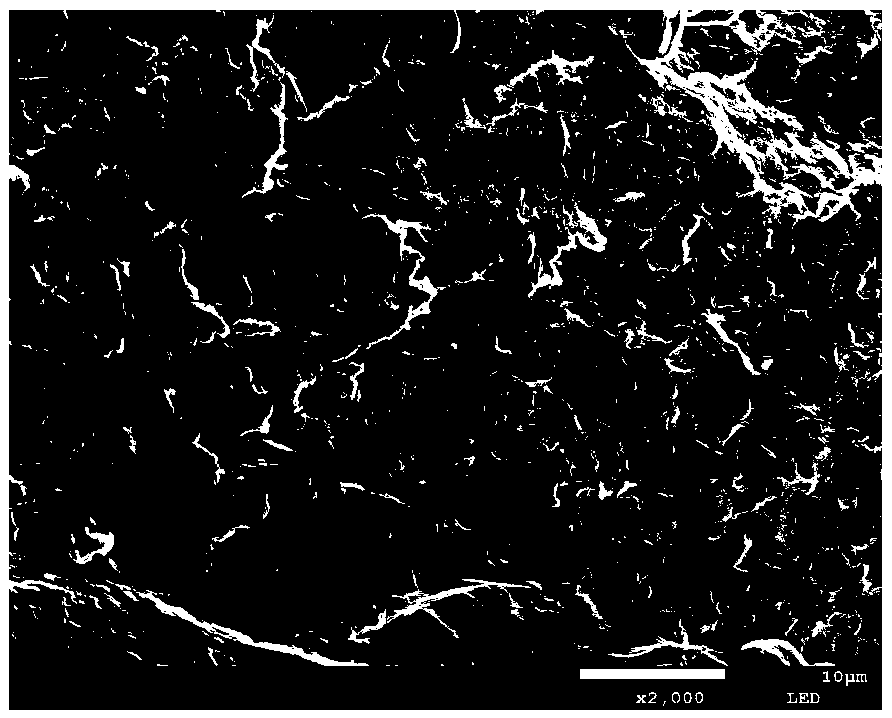

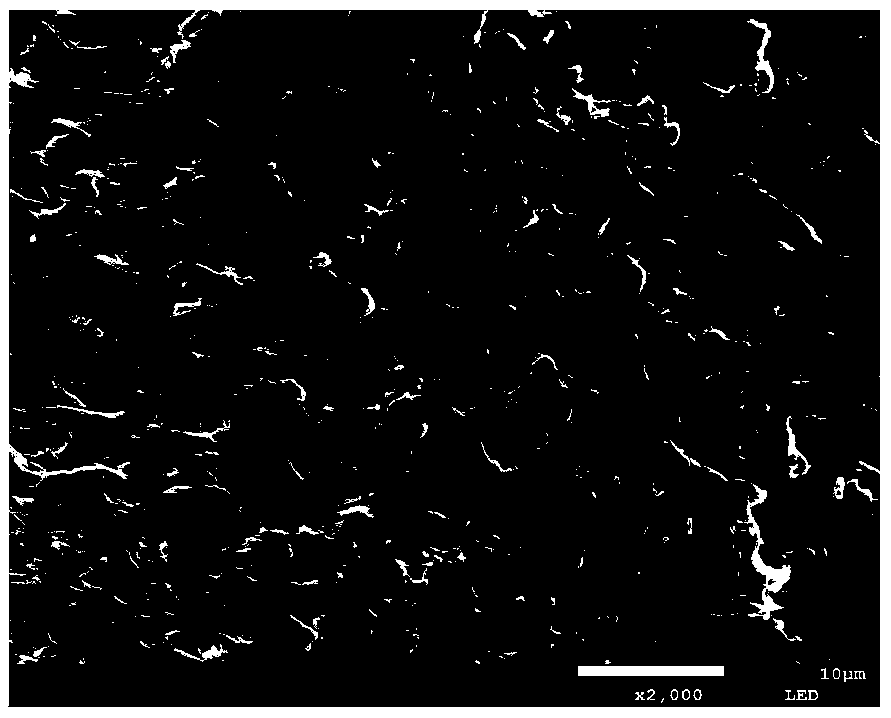

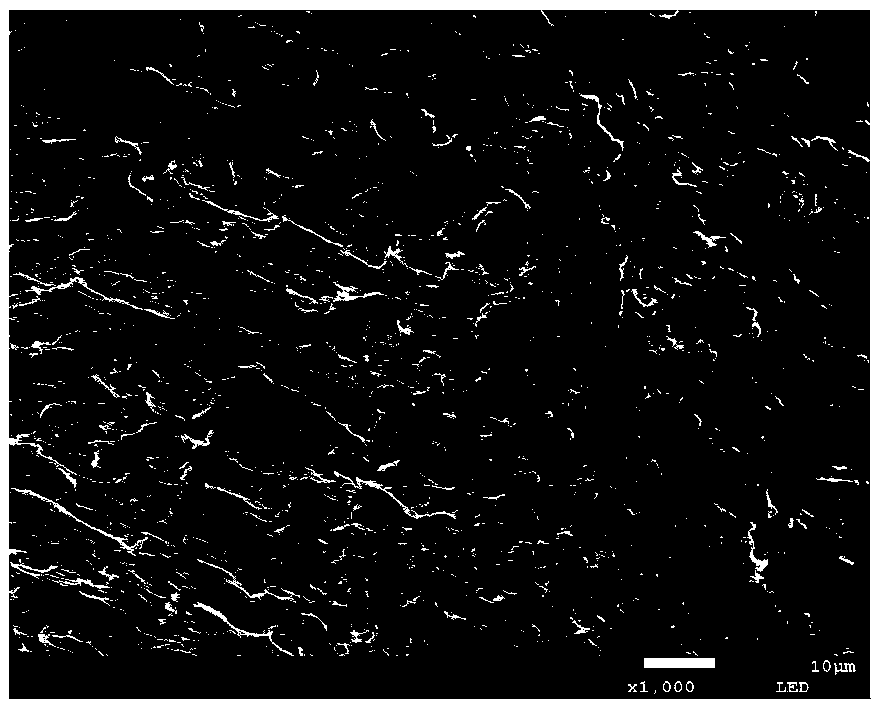

Image

Examples

Embodiment 1

[0031] SBS / SAN / nano CaCO3 The specific steps of the pressure-induced flow molding method of the system are as follows:

[0032] (1) The linear SBS (where S / B is 4 / 6), SAN and nano-CaCO 3 Dry at 70-80°C for 5 hours, then weigh according to the mass ratio of SAN:SBS=85 / 15 and add 0.1% of the total mass of SAN and SBS nano-CaCO 3 to mix. The ternary system is uniformly blended by high-strength shearing of the building-block twin-screw, and the temperature of the fourth stage of the twin-screw is set within the range of 150-235°C (zone 1: 150°C, zone 2: 200°C, zone 3: 230°C ℃, four zones: 235℃), and extruded through different die heads, preformed into wire or plate parisons with uniform thickness, and directly transported to the limited edge rolling through the temperature-controlled tunnel (temperature control is 80-130℃) device.

[0033] (2) Press the plate parison with a thickness of 4mm and a width of 5mm at 100°C with compression ratios of 1.0, 1.2 and 1.7, respectively, w...

Embodiment 2

[0040] SBS / SAN / nano CaCO 3 The specific steps of the pressure-induced flow molding method of the system are as follows:

[0041] (1) Thermoplastic elastomer (SBS is linear, wherein the ratio of S / B is 4 / 6), SAN and nano-CaCO 3 Dry 5 hours under the condition of 70-80 ℃, be SAN by mass ratio then: thermoplastic elastomer=85 / 15 and add the nano-CaCO of SAN and thermoplastic elastomer gross mass 1% 3 to mix. The ternary system is uniformly blended by high-strength shearing through the building-block twin-screw, and the temperature of the fourth stage of the twin-screw is set within the range of 150-235°C (zone 1: 150°C, zone 2: 200°C, zone 3: 230°C, zone 4 Zone: 235°C), extruded through different die heads, preformed into wire or plate parisons with uniform thickness, and directly transported to the edge-limiting rolling device through a temperature-controlled tunnel (temperature control is 80-130°C).

[0042] (2) Compress the plate parison with a thickness of 4mm and a width ...

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is that the compression ratio and the rigid particles of the third component are different. The compression ratio of this embodiment is 1.7, and pure SAN, Cu powder (Cu powder is 200 mesh), nano MMT, nano SiO 2 , Nano CaCO 3 , Nano TiO 2 And zeolite is added to the SBS / SAN system as rigid particles. As shown in Table 3, the data obtained from the impact test of the material sample strip prepared under the condition of SBS / SAN (15 / 85) 0.1% rigid particle ternary system parison at 100°C and the compression ratio of 1.7.

[0050] Table 3 Effect of adding different rigid particles on the performance of SBS / SAN(15 / 85) ternary system

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com