Asphalt regenerant prepared from waste lubricating oil and preparation method for asphalt regenerant

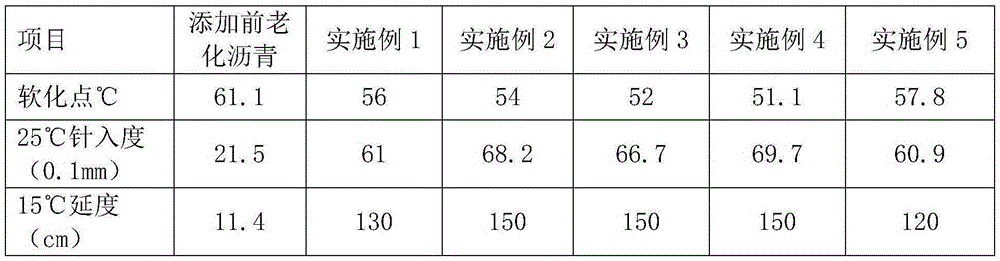

A technology for waste lubricating oil and asphalt rejuvenating agent, which is applied to the field of asphalt rejuvenating agent prepared from waste lubricating oil and its preparation, can solve the problems of high preparation components, high resource consumption, etc., achieves huge economic value, simple preparation method, Highlight the effect of environmental protection and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

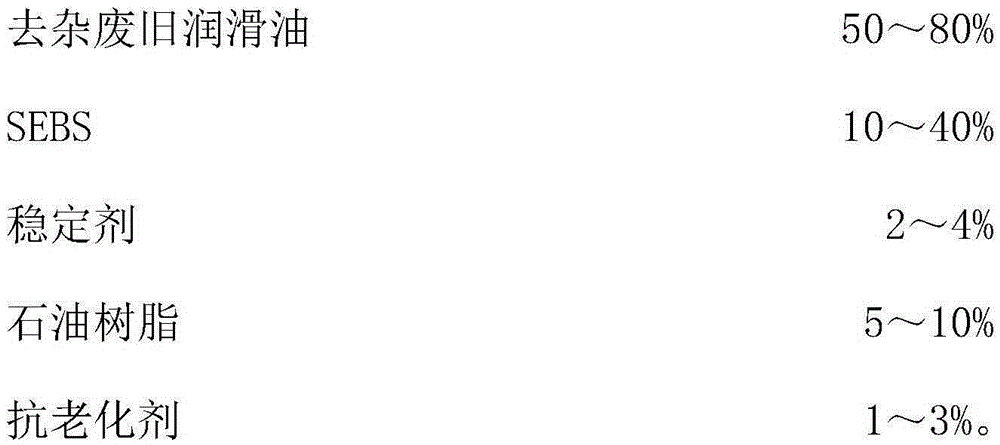

Method used

Image

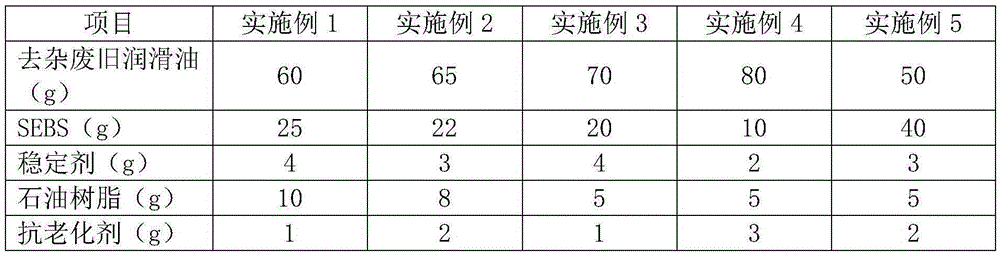

Examples

Embodiment 1

[0024] The bitumen regeneration agent that present embodiment uses waste lubricating oil to produce is by removing impurity waste automobile lubricating oil, SEBS (with polystyrene as the end section, with the ethylene-butene copolymer obtained by hydrogenation of polybutadiene as the middle elastic Block linear triembedded copolymer, which belongs to common materials of asphalt modifier), dicumyl peroxide, C9 hydrogenated petroleum resin and carbon black are prepared according to the formula quantity, and the specific formula quantity is shown in Table 1.

[0025] The concrete preparation method of the asphalt regeneration agent that above-mentioned produces with waste lubricating oil is realized by following steps:

[0026] (1) Add NaOH solution with a mass concentration of 60% to the waste automobile lubricating oil, the NaOH solution accounts for 3% of the mass of the waste automobile lubricating oil, stir evenly and let stand for 25 minutes, heat to 75°C, let stand and set...

Embodiment 2

[0030] The asphalt rejuvenator prepared from waste lubricating oil in this example is prepared from impurity-removed waste gear oil, SEBS, straight-chain aliphatic hydrocarbons, C5 hydrogenated petroleum resin, and slaked lime according to the formula quantity. The specific formula quantity is shown in Table 1.

[0031] The concrete preparation method of the asphalt regeneration agent that above-mentioned produces with waste lubricating oil is realized by following steps:

[0032] (1) Add a NaOH solution with a mass concentration of 60% to the waste gear oil, the NaOH solution accounts for 2% of the waste gear oil mass, stir evenly and let it stand for 20 minutes, heat it to 70°C, let it settle for 20 hours, and take the supernatant Obtain de-impured waste lubricating oil;

[0033] (2) Heat the old lubricating oil for impurities removal to 110°C, add the formulated amount of SEBS, and initially swell for 28 minutes, then cut at a speed of 19,000r / min for 50 minutes, and swell ...

Embodiment 3

[0036] The asphalt rejuvenating agent prepared by the waste lubricating oil in this embodiment is prepared according to the formula quantity by de-impurity waste hydraulic oil, SEBS, stabilizer, petroleum resin and anti-aging agent, wherein the stabilizer is dicumyl peroxide and direct The chain aliphatic hydrocarbons are mixed according to the mass ratio of 1:2. The petroleum resin is made by mixing C5 hydrogenated petroleum resin and C9 hydrogenated petroleum resin according to the mass ratio of 1:1. The anti-aging agent is thiodipropionic acid two lauryl esters. See Table 1 for specific formula quantities.

[0037] The concrete preparation method of the asphalt regeneration agent that above-mentioned produces with waste lubricating oil is realized by following steps:

[0038] (1) Add NaOH solution with a mass concentration of 60% to the waste hydraulic oil, the NaOH solution accounts for 5% of the waste hydraulic oil mass, stir evenly and let stand for 30min, heat to 80°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com