Cyclodextrin aqueous anticorrosive paint and preparation method thereof

An anti-corrosion coating and cyclodextrin technology, applied in cyclodextrin coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of poor barrier performance, stress cracking, protection defects, etc., to improve poor dispersion and improve barrier properties. performance, the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with specific examples.

[0020] This embodiment provides a cyclodextrin water-based anti-corrosion coating, which is composed of cyclodextrin-modified nano-inorganic filler, water-based epoxy resin, water-based curing agent, and water.

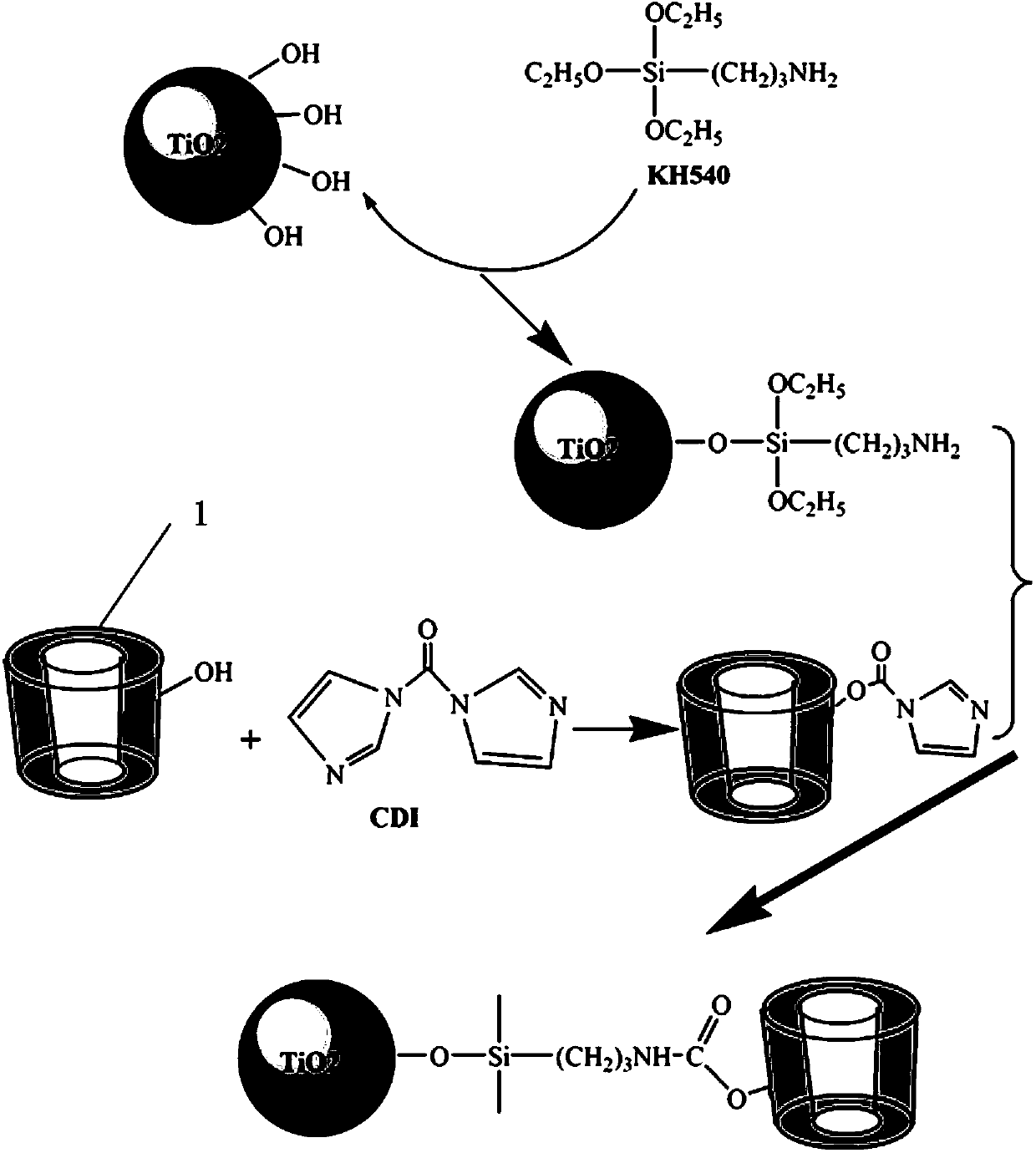

[0021] see figure 1 , this embodiment also provides a preparation method of cyclodextrin water-based anti-corrosion coating, including the following steps.

[0022] Step 1. Weigh 10g of nano-mesoporous titanium dioxide and 50mL of toluene into a clean three-necked flask, stir and reflux at room temperature for 40min; add 2g of silane coupling agent to the reaction system, stir and reflux at 100°C After 6 hours, the ammonium propyl group can be introduced on the surface of the nano-inorganic filler, and then centrifuged, and washed 3 times with toluene solution, acetone solution and distilled water respectively; the obtained solid is dried at 150°C for 6 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com