Waterborne polyurethane wallpaper glue

A water-based polyurethane and wallpaper adhesive technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of high formaldehyde and benzene content, unstable storage of wallpaper adhesives, water resistance, and cold resistance of the adhesive layer And problems such as poor temperature resistance, to achieve the effect of no formaldehyde release, easy control, and high bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

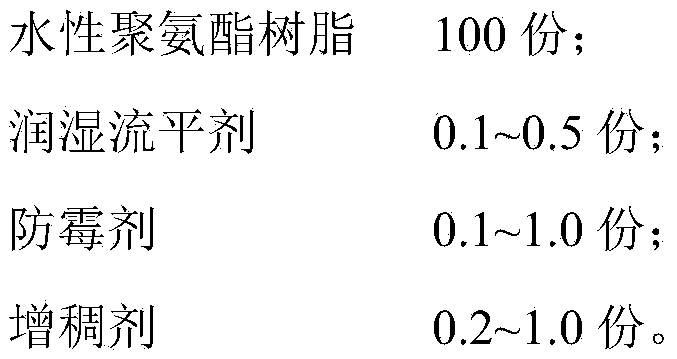

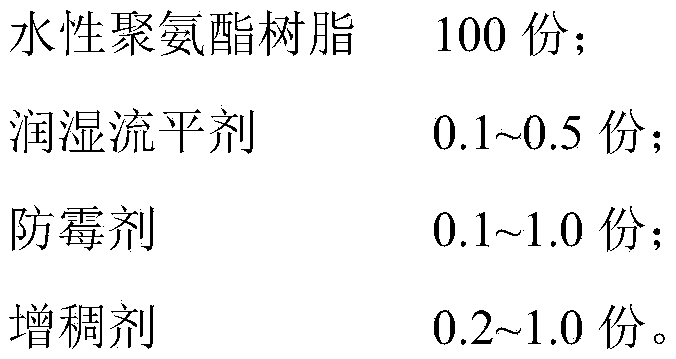

[0044] The water-based PU resin in Example 1 is the KT703B water-based PU resin of Hefei Ketian Chemical Co., Ltd., the solid content of the water-based PU resin is 35-37%, the viscosity is 1000CPS-2000CPS, the breaking strength is 12-17MPa, and the elongation is 500-600%, the wetting and leveling agent is TEGO270 organic silicon leveling agent from Germany, and the anti-mold agent is OIT-W heterocyclic (zinc pyrithione) anti-mold additive of Guangzhou Runhong Chemical Company, thickening The agent is Rohm and Haas RM2020 associative thickener.

[0045] Take 100g of Hefei Ketian Chemical Co., Ltd. KT703B water-based PU resin and place it in a 500ml beaker, then slowly add 0.1g of wetting and leveling agent, 0.1g of antifungal agent and 0.2g of thickener while stirring at a low speed, and defoam Finally, water-based polyurethane wallpaper glue is obtained.

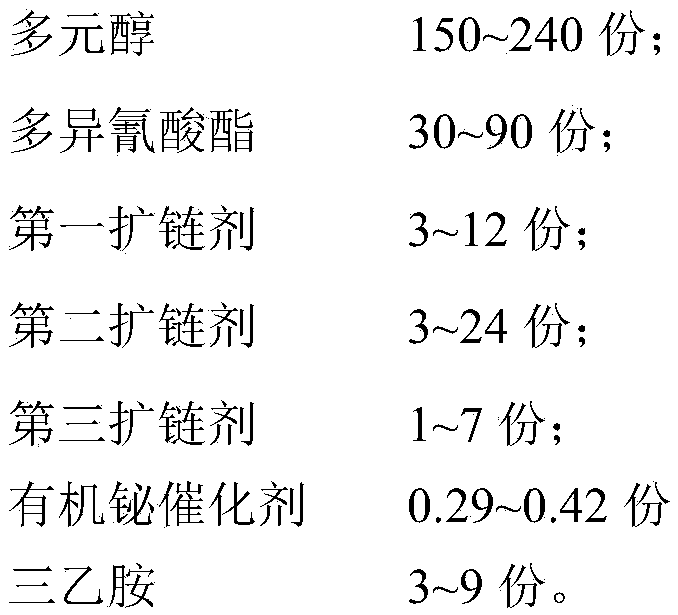

[0046] Among them, the preparation process of KT703B water-based PU resin of Hefei Ketian Chemical Co., Ltd. includes th...

Embodiment 2

[0048] The water-based PU resin in Example 2 is the KT703B water-based PU resin of Hefei Ketian Chemical Co., Ltd., the solid content of the water-based PU resin is 35-37%, the viscosity is 1000CPS-2000CPS, the breaking strength is 12-17MPa, and the elongation is 500-600%, the wetting and leveling agent is TEGO270 organic silicon leveling agent from Germany, and the anti-mold agent is OIT-W heterocyclic (zinc pyrithione) anti-mold additive of Guangzhou Runhong Chemical Company, thickening The agent is Rohm and Haas RM2020 associative thickener.

[0049] Take 100g of Hefei Ketian Chemical Co., Ltd. KT703B water-based PU resin and place it in a 500ml beaker, then slowly add 0.4g of wetting and leveling agent, 0.7g of antifungal agent and 0.8g of thickener while stirring at a low speed, and defoam Finally, water-based polyurethane wallpaper glue is obtained.

Embodiment 3

[0051] The water-based PU resin in Example 3 is the KT703B water-based PU resin of Hefei Ketian Chemical Co., Ltd., the solid content of the water-based PU resin is 35-37%, the viscosity is 1000CPS-2000CPS, the breaking strength is 12-17MPa, and the elongation is 500-600%, the wetting and leveling agent is TEGO270 organic silicon leveling agent from Tego, Germany, and the anti-mold agent is OIT-W heterocyclic (zinc pyrithione) anti-mold additive of Guangzhou Runhong Chemical Company. The thickener is Rohm and Haas RM2020 associative thickener.

[0052] Take 100g of Hefei Ketian Chemical Co., Ltd. KT703B water-based PU resin and place it in a 500ml beaker, then slowly add 0.3g of wetting and leveling agent, 0.5g of antifungal agent and 0.6g of thickener while stirring at a low speed, and defoam Finally, water-based polyurethane wallpaper glue is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com