Small-molecular clean fracturing fluid and preparation method and application thereof

A technology for cleaning fracturing fluid and fracturing fluid, applied in the field of fracturing fluid, can solve problems such as high price, filter cake damage, blockage, etc., and achieve the effects of complete gel breaking, small filtration loss and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing small molecule clean fracturing fluid, which comprises the following steps:

[0034] At room temperature, prepare 200 mL of an aqueous solution containing 0.5 wt % potassium chloride;

[0035] Dissolve 1.6g of octadecyltrimethylammonium chloride and 0.04g of fatty alcohol polyoxyethylene ether (AEO-3) in 4g of isopropanol, and mix uniformly to obtain a thickener solution;

[0036] At a constant temperature of 50°C, add the thickener solution to the prepared potassium chloride aqueous solution, continue stirring to form a uniform mixed solution, and then cool to room temperature;

[0037] Finally, 1.0 g of sodium salicylate was added to the above mixed solution, stirred until a uniform gel was formed, and aged at 35° C. for 24 hours to obtain a small-molecule clean fracturing fluid.

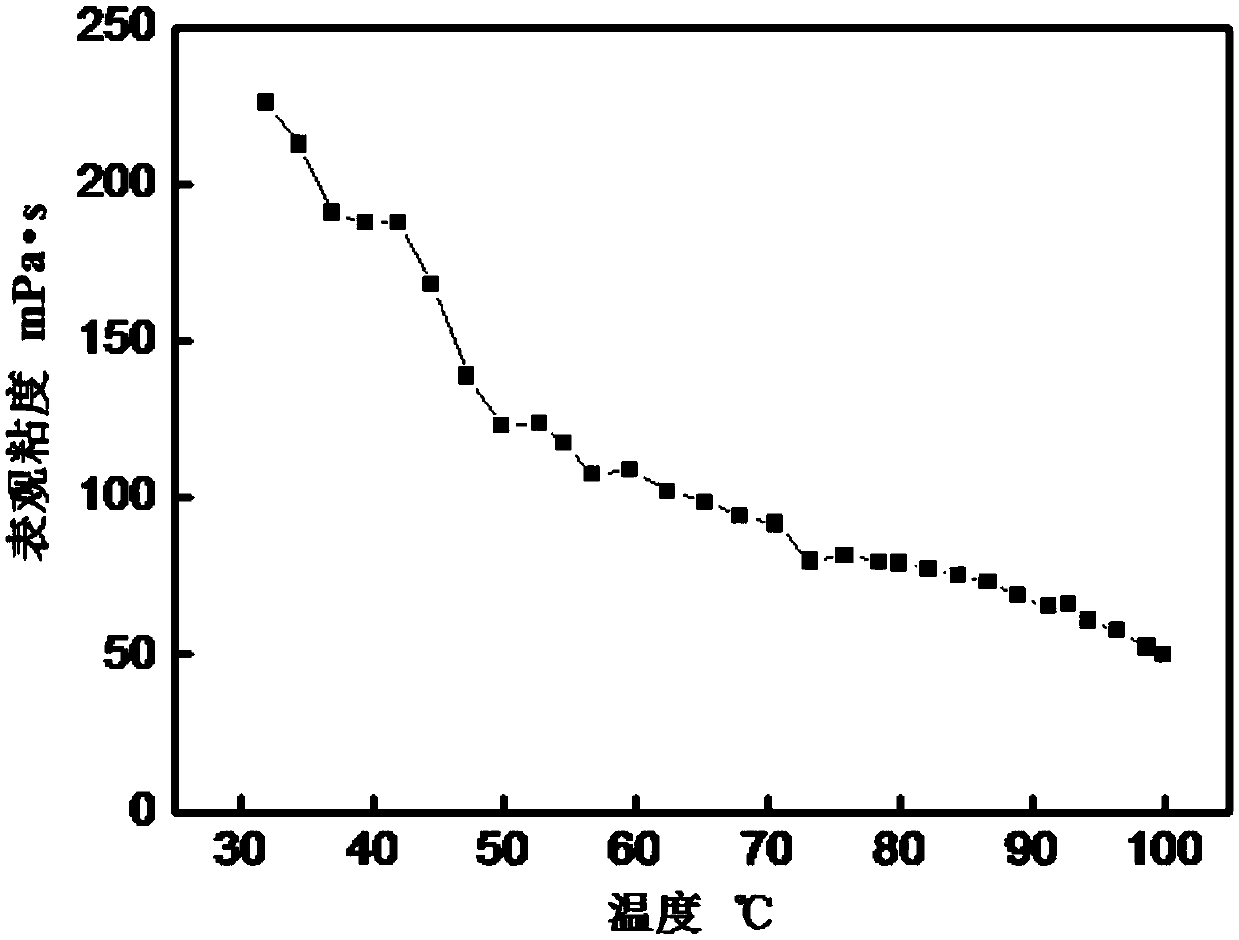

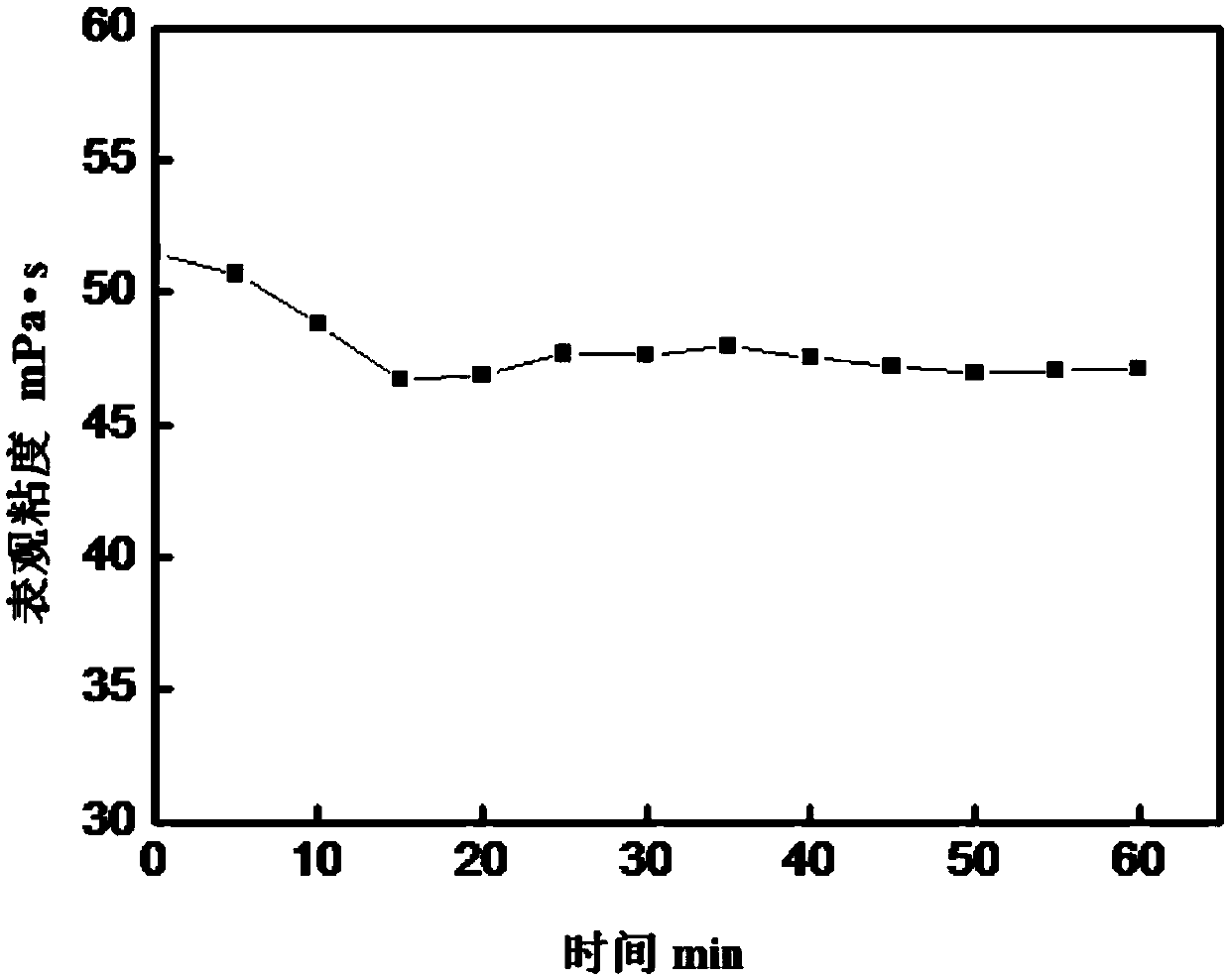

[0038] The small molecule clean fracturing fluid provided by this embodiment is in 170s -1 The viscosity-temperature curve under figure 1 ...

Embodiment 2

[0046] This embodiment provides a method for preparing small molecule clean fracturing fluid, which comprises the following steps:

[0047] At room temperature, prepare 200 mL of an aqueous solution containing 0.6 wt % potassium chloride;

[0048] Dissolve 3.6g of octadecyltrimethylammonium chloride and 0.06g of fatty alcohol polyoxyethylene ether (AEO-3) in 4g of isopropanol, and mix uniformly to obtain a thickener solution;

[0049] At a constant temperature of 50°C, add the thickener solution to the prepared potassium chloride aqueous solution; keep stirring to form a uniform mixed solution, and then cool to room temperature;

[0050] Finally, 2.0 g of sodium salicylate was added to the mixed solution, stirred until a uniform jelly was formed, and aged at room temperature for 24 hours to obtain a small-molecule clean fracturing fluid.

Embodiment 3

[0052] This embodiment provides a method for preparing small molecule clean fracturing fluid, which comprises the following steps:

[0053] At room temperature, prepare 200 mL of an aqueous solution containing 0.6 wt % potassium chloride;

[0054] Dissolve 5.6g behenyltrimethylammonium chloride and 0.07g fatty alcohol polyoxyethylene ether (AEO-3) in 6g isopropanol, and mix well to obtain a thickener solution;

[0055] At a constant temperature of 50°C, add the thickener solution into the prepared potassium chloride aqueous solution, continue stirring to form a uniform mixed solution, and then cool to room temperature;

[0056] Finally, 2.3 g of sodium salicylate was added to the above mixed solution, stirred until a uniform jelly was formed, and aged at room temperature for 24 hours to obtain a small-molecule clean fracturing fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com