Textile fluoride-free waterproofing agent and preparation method thereof and textile

A fluorine-free water repellent, textile technology, applied in textiles and papermaking, fiber processing, liquid repellent fibers, etc., to achieve the effect of reducing the requirements of preparation equipment, good compatibility, and simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of chemically modified chitosan:

[0053] Add 20g of chitosan, 60mL of dimethylformamide (DMF) and 20mL of pyridine to a 250mL round-bottomed flask and stir thoroughly, then add 40g of toluene diisocyanate, place the reaction bottle in an oil bath and heat to reflux. The reaction was carried out for 10 hours at a temperature of 85°C. After the reaction was completed, it was cooled to room temperature, washed and dried to obtain chemically modified chitosan. It can be seen that the mass ratio of modifier and chitosan is 2:1 in the present embodiment.

[0054] Prepare waterproofing agent:

[0055] Take 8g behenyl acrylate, 8g behenyl methacrylate, 2g styrene, 5g dipropylene glycol, 3g chemically modified chitosan, 1g glycidyl acrylate, 0.2g acetic acid, 30g (modified) polyethylene Wax emulsion (particle size 150nm), 42.6g of water, heating up to 85°C, high-speed emulsification for 60 minutes to obtain a pre-emulsion; and nitrogen gas for 30 minutes, while co...

Embodiment 2

[0058] Preparation of chemically modified chitosan:

[0059] Except that the mass ratio of modifier and chitosan is 0.05:1, other raw material consumption and method are the same as in Example 1.

[0060] Prepare waterproofing agent:

[0061] The preparation method and the control of parameters such as temperature and emulsification time during the preparation process are the same as in Example 1.

[0062] The addition amount of each component is as follows:

[0063] 2g behenyl acrylate, 2g behenyl methacrylate, 0.5g styrene, 1.25g dipropylene glycol, 15g chemically modified chitosan, 5g (modified) polyethylene wax emulsion (particle size 150nm), 0.25 g glycidyl acrylate, 0.05 g acetic acid, 73.6 g water, 0.1 g azobisisobutylamidine hydrochloride, 0.25 g vinyl chloride.

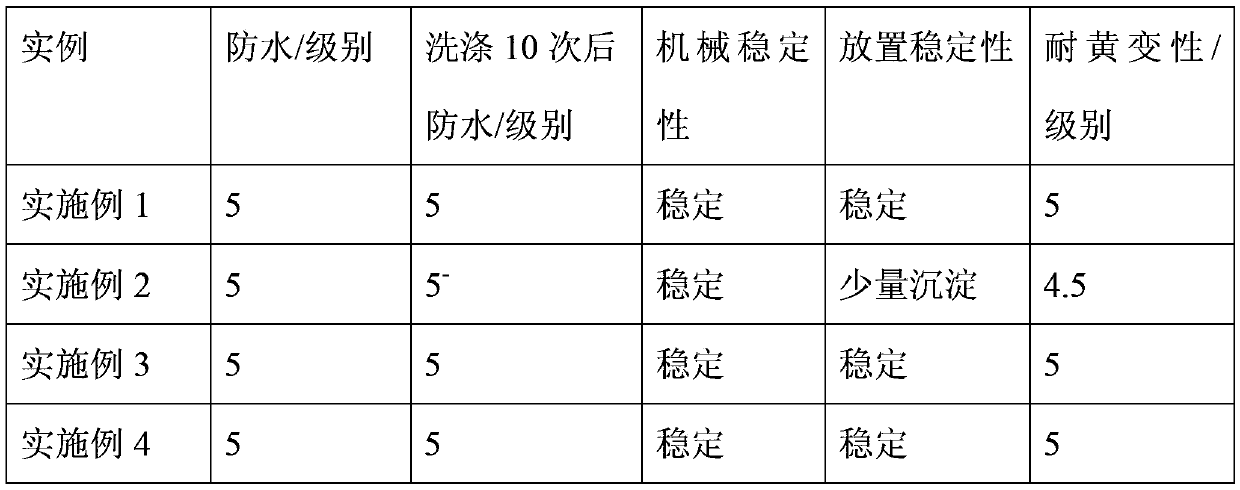

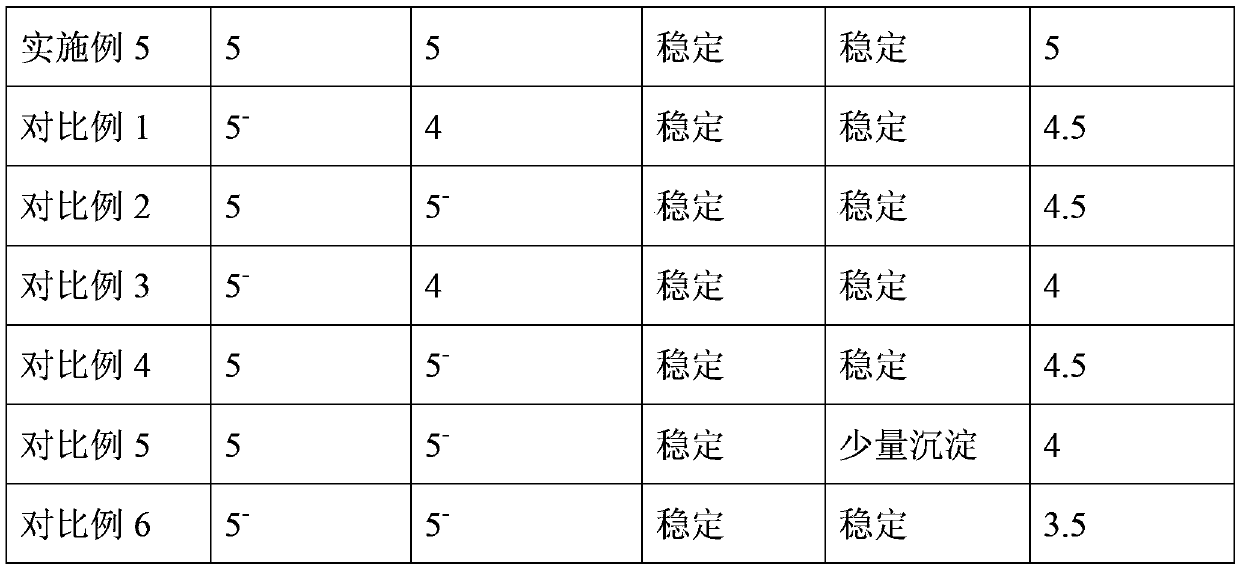

[0064] The performance test of the prepared fluorine-free waterproofing agent was carried out, and the test results are listed in Table 1.

Embodiment 3

[0066] Preparation of chemically modified chitosan:

[0067] Except that the mass ratio of modifier to chitosan is 1:1, the dosage and method of other raw materials are the same as in Example 1.

[0068] Prepare waterproofing agent:

[0069] The preparation method and the control of parameters such as temperature and emulsification time during the preparation process are the same as in Example 1.

[0070] The addition amount of each component is as follows:

[0071] 12g behenyl acrylate, 15g (modified) polyethylene wax emulsion (particle size 150nm), 12g behenyl methacrylate, 1.5g glycidyl acrylate, 0.3g acetic acid, 3g styrene, 7.5g dipropylene glycol , 10g chemically modified chitosan, 36.65g water, 1.5g vinyl chloride, 0.3g azobisisobutylamidine hydrochloride, 0.25g vinyl chloride.

[0072] The performance test of the prepared fluorine-free waterproofing agent was carried out, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com