A freeze-dried composite fruit and vegetable granule with high nutritional value and rapid disintegration

A nutritional value, fruit and vegetable technology, applied in the field of freeze-dried fruit and vegetable solid food, can solve the problems of unable to swallow solid food normally, less development of fruit and vegetable solid food, defective chewing function, etc., and achieve strong anti-oxidation ability, strong disintegration ability, Ease of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

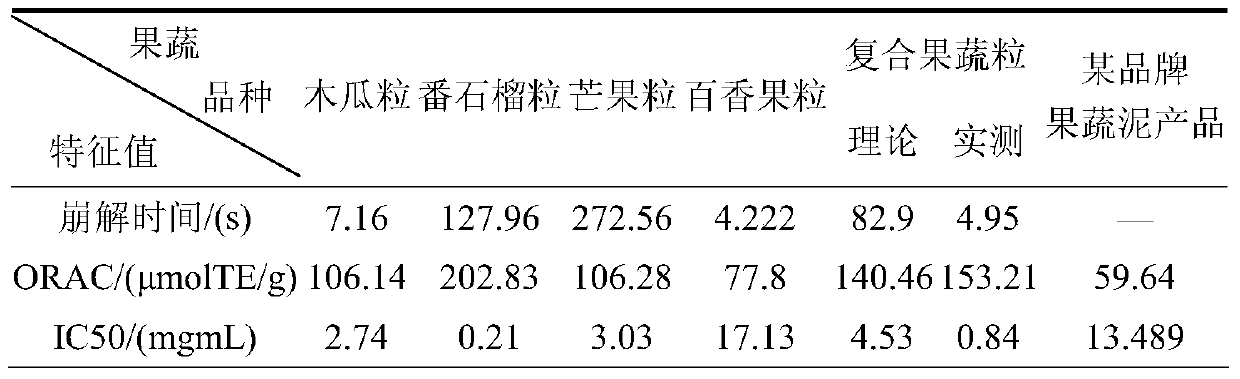

Embodiment 1

[0031] A method for processing freeze-dried composite fruit and vegetable granules with high nutritional value and rapid disintegration, comprising the following steps:

[0032] (1) Preparation of fruit and vegetable puree:

[0033] Select fresh and high-quality papaya, guava, mango and passion fruit that are free from pests and have not deteriorated, peeled and pitted to obtain the edible parts of the fruits and vegetables, and then use a beater to crush them separately to obtain papaya puree, guava puree, Mango puree and passion fruit puree;

[0034] (2) Mixing:

[0035] In parts by weight, 29.3 parts of papaya puree, 41.2 parts of guava puree, 10.0 parts of mango puree and 19.5 parts of passion fruit puree were uniformly mixed to obtain fruit and vegetable mixed pulp;

[0036] (3) Forming of fruit and vegetable granules:

[0037] Pour the mixed fruit and vegetable slurry into the mold, freeze and form it quickly to obtain composite fruit and vegetable granules;

[0038]...

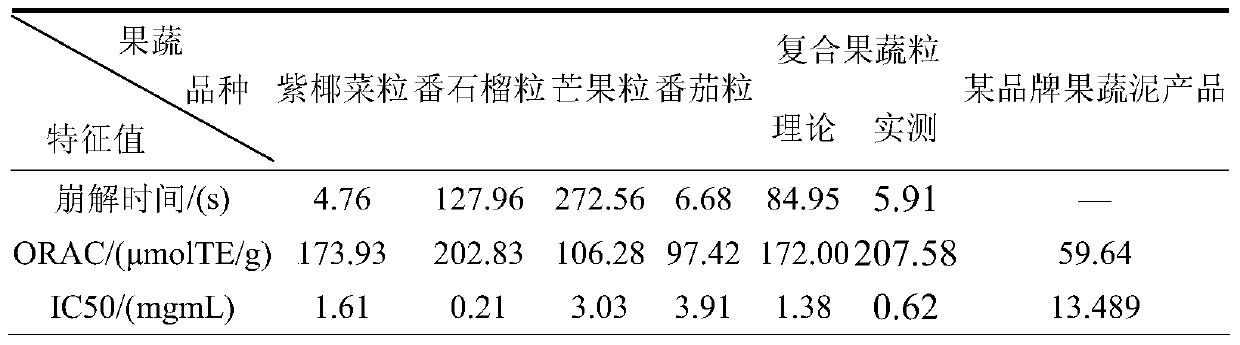

Embodiment 2

[0055] A method for processing freeze-dried composite fruit and vegetable granules with high nutritional value and rapid disintegration, comprising the following steps:

[0056] (1) Preparation of fruit and vegetable puree:

[0057] Select fresh and high-quality papaya, purple cabbage, tomato, guava, mango, and passion fruit that are free from pests and have not deteriorated, peeled and pitted to obtain the edible parts of fruits and vegetables, and then use a beater to crush them separately to obtain papaya puree , purple cabbage puree, tomato puree, guava puree, mango puree and passion fruit puree;

[0058] (2) Mixing:

[0059] According to parts by weight, 70 parts of papaya puree, 70 parts of purple cabbage puree, 60 parts of tomato puree, 60 parts of guava puree, 60 parts of mango puree and 60 parts of passion fruit puree are mixed uniformly to obtain mixed fruit and vegetable pulp;

[0060] (3) Forming of fruit and vegetable granules:

[0061] Pour the mixed fruit an...

Embodiment 3

[0076] The step (2) compounding of this implementation:

[0077] In parts by weight, 20 parts of papaya puree, 20 parts of purple cabbage puree, 10 parts of tomato puree, 10 parts of guava puree, 10 parts of mango puree and 10 parts of passion fruit puree are mixed evenly to obtain mixed fruit and vegetable pulp;

[0078] The specific operation of the described step (4) of this implementation is as follows:

[0079] Pre-freezing: When the temperature of the cold trap of the lyophilizer reaches -35°C, put the tray containing fruit and vegetable granules into the freezing area of the lyophilizer for pre-freezing, and the pre-freezing time is 3 hours;

[0080] Drying: Move the pre-frozen tray to the drying area, turn on the vacuum pump, and when the vacuum degree of the drying room is lower than 100Pa, turn on the heating plate, and perform freeze-drying according to the heating program of 70°C 5h—60°C 8h—50°C 4h.

[0081] Other steps and parameters in this embodiment are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com