Preparation method of leisure lotus root chips

A technology for lotus root and chips is applied in the field of preparation of lotus root leisure chips, which can solve the problems of low retention rate of nutrients, large energy consumption in production process, long hot air drying time, etc., and achieves long storage time, low production cost and easy operation The effect of long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

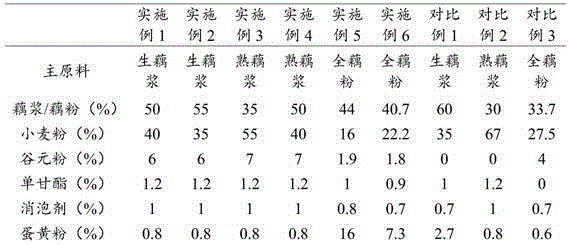

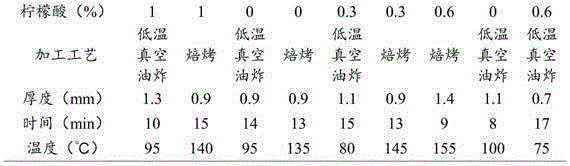

Embodiment 1

[0025] A production process of lotus root leisure crisp food: select fresh lotus root, wash and remove lotus root joints, add 33-37 kg of water per 100 kg of fresh lotus root, and use a beating machine to make lotus root pulp. The lotus root paste of 50 parts by weight, the wheat flour of 40 parts by weight, the gluten of 6 parts by weight, the monoglyceride of 1.2 parts by weight, the defoamer of 1.0 parts by weight, the citric acid of 1.0 parts by weight, the egg yolk of 0.8 parts by weight The flour is added to the mixer and mixed thoroughly to obtain a dough with good extensibility. The dough is uniformly extruded by a dough press at room temperature to prepare a rough dough sheet. The rough dough sheet was re-extruded, so that the thickness of the dough sheet after pressing was 1.3 mm, and then several round dough sheets were prepared by punching the dough sheet with a die, and the frying time was 10 minutes at a low temperature of 95 ℃. The paint is vacuum packed.

Embodiment 2

[0027] A production process of lotus root leisure crisp food: select fresh lotus root, wash and remove lotus root joints, add 33-37 kg of water per 100 kg of fresh lotus root, and use a beating machine to make lotus root pulp. The lotus root paste of 55 parts by weight, the wheat flour of 35 parts by weight, the gluten of 6 parts by weight, the monoglyceride of 1.2 parts by weight, the defoamer of 1.0 parts by weight, the citric acid of 1.0 parts by weight, the egg yolk of 0.8 parts by weight The flour is added to the mixer and mixed thoroughly to obtain a dough with good extensibility. The dough is uniformly extruded by a dough press at room temperature to prepare a rough dough sheet. The rough dough sheet was re-extruded so that the thickness of the dough sheet after pressing was 0.9 mm, and then several round dough sheets were prepared by punching the dough sheet with a die, baked at 140°C for 15 minutes, and finally vacuum-packed with paint. .

Embodiment 3

[0029] A production process of lotus root leisure crisp food: select fresh lotus root, wash and cook at 121 DEG C for 15 minutes, add 28-32 kg of water per 100 kg of fresh lotus root, and use a beater to make lotus root pulp. Add the lotus root paste of 35 parts by weight, the wheat flour of 55 parts by weight, the gluten of 7 parts by weight, the monoglyceride of 1.2 parts by weight, the defoamer of 1.0 parts by weight, the egg yolk powder of 0.8 parts by weight in the mixer and mix thoroughly. , a dough with good extensibility was obtained. The dough is uniformly extruded by a dough press at room temperature to prepare a rough dough sheet. The rough dough sheet was re-extruded, so that the thickness of the dough sheet after pressing was 0.9 mm, and then a number of circular dough sheets were prepared by punching the dough sheet with a die. The paint is vacuum packed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com