Preparation method for fermentative production of marine peptides streptozotocin by using sea cucumber leftovers

A technology of leftovers and peptinomycin, applied in the field of food processing, can solve the problems of deep, fine and fine processing technology lag, waste of aquatic resources, pollution, etc., and achieve the effects of high production efficiency, high-value utilization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

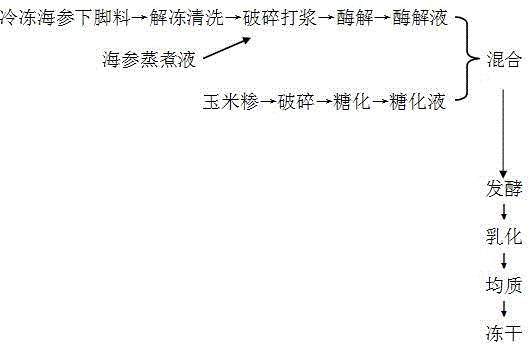

Method used

Image

Examples

Embodiment 1

[0024] (1) Raw material pretreatment: thaw the frozen sea cucumber scraps and wash them with water for 2-3 times. After thorough cleaning, send them to the pulverizer, add the sea cucumber cooking liquid to crush and beat the slurry, heat the slurry to 60°C and add the concentration of 1% by mass. % of commercially available papain was incubated for 14 hours, and then cooled to 28°C quickly after the enzymatic hydrolysis.

[0025] (2) Crushing of corn grits: select degerminated corn grits, wash them to remove iron and impurities, send them to the crusher, and crush them according to 0.3mm to make corn grits of 0.1-0.3mm.

[0026] (3) Saccharification: Mix corn grits and purified water according to the material-to-liquid ratio of 1:4 (w / v), put them into a mash tank, raise the temperature to 60°C and keep saccharification, and saccharify for 70 minutes. 28Brix stops saccharification, and the corn grits saccharification solution is cooled to 28°C for later use.

[0027] (4) Fer...

Embodiment 2

[0031] (1) Raw material pretreatment: thaw the frozen sea cucumber scraps and wash them with water for 2-3 times. After thorough cleaning, send them to the pulverizer, add sea cucumber cooking liquid to crush and beat the slurry, and heat the slurry to 62°C. Add the mass percent concentration to 1 % of commercially available papain was incubated for 14 hours, and then cooled to 29°C quickly after the enzymolysis.

[0032] (2) Crushing of corn grits: select degerminated corn grits, wash them to remove iron and impurities, send them to the crusher, and crush them according to 0.3mm to make corn grits of 0.1-0.3mm.

[0033] (3) Saccharification: Mix corn grits and purified water according to the material-to-liquid ratio of 1:4 (w / v), put them into a mash tank, raise the temperature to 62°C and keep saccharification, and saccharify for 65 minutes. 30Brix stops saccharification, and the corn grits saccharification solution is cooled to 29°C for later use.

[0034] (4) Fermentation...

Embodiment 3

[0038] (1) Raw material pretreatment: thaw the frozen sea cucumber scraps and wash them with water for 2-3 times. After thorough cleaning, send them to the pulverizer, add the sea cucumber cooking liquid to crush and beat the slurry, and heat the slurry to 65°C and add the concentration of 1% by mass. % of commercially available papain was incubated for 14 hours, and then rapidly cooled to 30°C after enzymatic hydrolysis.

[0039] (2) Crushing of corn grits: select degerminated corn grits, wash them to remove iron and impurities, send them to the crusher, and crush them according to 0.3mm to make corn grits of 0.1-0.3mm.

[0040] (3) Saccharification: Mix corn grits and purified water according to the material-to-liquid ratio of 1:4 (w / v), put them into a mash tank, raise the temperature to 65°C and keep saccharification, and saccharify for 60 minutes. 31Brix stops saccharification, and the corn grits saccharification solution is cooled to 30°C for later use.

[0041] (4) Fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com