Method for evaluating microcrack initiation of magnesium alloy

A micro-crack, magnesium alloy technology, applied in the field of testing, can solve the problem of not considering the grain orientation around the grain boundary, and achieve the effect of improving the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following implementations. example.

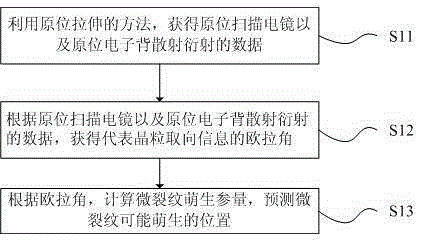

[0036] Combine Figure 1-Figure 3 , A detailed description of the method of the present invention for evaluating the initiation of magnesium alloy microcracks, such as figure 1 Shown as its flowchart, which includes the following steps:

[0037] S11: Use the in-situ stretching method to obtain in-situ scanning electron microscopy (SEM) and in-situ electron backscatter diffraction (EBSD) data;

[0038] S12: Obtain the Euler angle representing the orientation information of the crystal grains based on the in-situ scanning electron microscope (SEM) and in-situ electron backscatter diffraction (EBSD) data through OIM software;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com